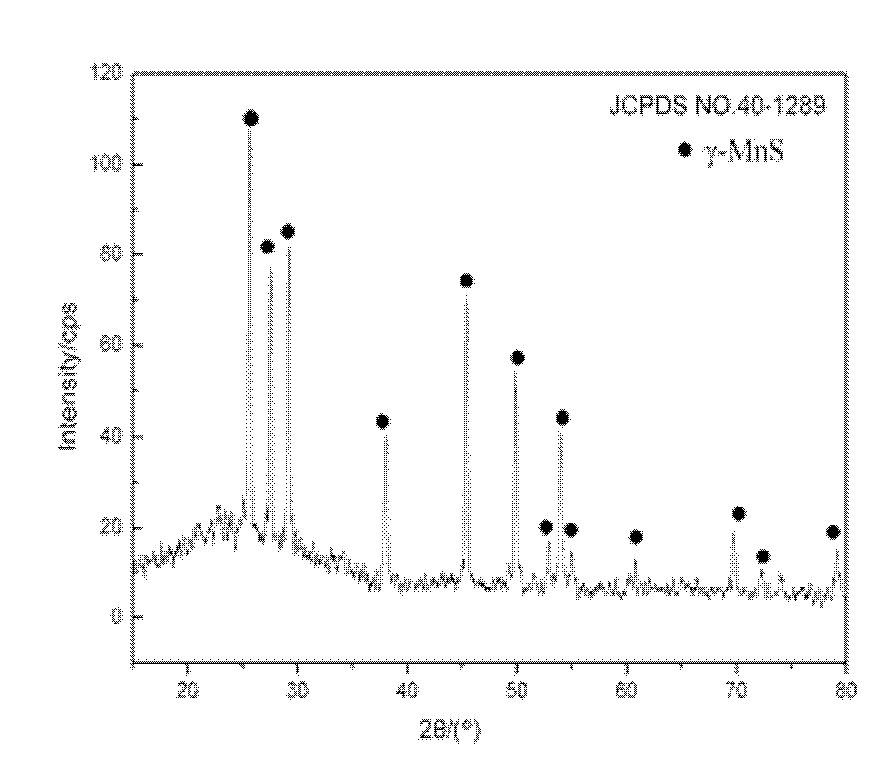

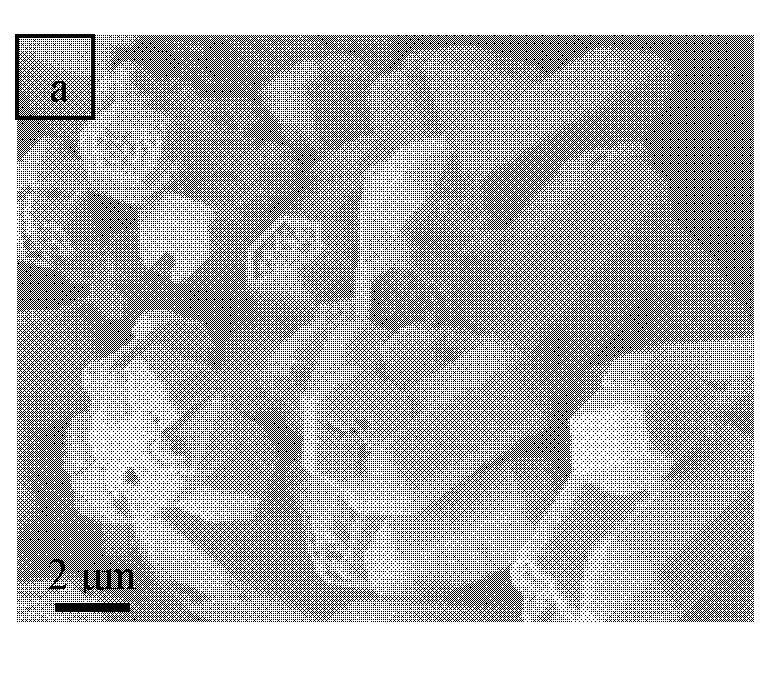

Preparation method of pencil-shaped gamma-MnS microcrystal

A pencil and microcrystalline technology, which is applied in the field of preparation of manganese sulfide, a wide bandgap semiconductor material, can solve problems such as difficult process control, low reaction rate, and complexity, and achieve the effects of short reaction cycle, reduced activation energy, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Analytical pure manganese chloride (MnCl 2 4H 2 O) added to deionized water to make Mn 2+ A transparent solution A with a concentration of 0.1mol / L;

[0017] 2) Add analytically pure thioacetamide (C 2 h 5 NS), so that the Mn in the solution 2+ / C 2 h 5 The molar ratio of NS is 1:0.8, and the solution is ultrasonically dispersed to obtain solution B;

[0018] 3) Pour solution B into a flask and seal it, then put the sealed flask into a microwave-ultraviolet-ultrasonic three-in-one synthetic extraction reaction apparatus, select the "temperature-time" working mode, set the temperature at 85°C, and the magnetic stirring speed 400r / min, add ultraviolet energy, the output power of the ultraviolet lamp is 300W, after reacting for 30min, solution C is obtained;

[0019] 4) Pour solution C into a microwave hydrothermal reactor with a filling degree of 55%, then seal the reactor, put it into a microwave hydrothermal reactor with temperature and pressure dual control,...

Embodiment 2

[0023] 1) Analytical pure manganese chloride (MnCl 2 4H 2 O) added to deionized water to make Mn 2+ A transparent solution A with a concentration of 0.3mol / L;

[0024] 2) Add analytically pure thioacetamide (C 2 h 5 NS), so that the Mn in the solution 2+ / C 2 h 5 The molar ratio of NS is 1:0.5, and the solution is ultrasonically dispersed to obtain solution B;

[0025] 3) Pour solution B into a flask and seal it, then put the sealed flask into a three-in-one microwave, ultraviolet, and ultrasonic three-in-one synthetic extraction reaction apparatus, select the "temperature-time" working mode, set the temperature at 80°C, and the magnetic stirring speed The temperature is 380r / min, add ultraviolet energy, the output power of the ultraviolet lamp is 300W, and the solution C is obtained after 40min of reaction;

[0026] 4) Pour solution C into a microwave hydrothermal reaction kettle with a filling degree of 50%, then seal the reaction kettle, put it into a microwave hydr...

Embodiment 3

[0029] 1) Analytical pure manganese chloride (MnCl 2 4H 2 O) added to deionized water to make Mn 2+ A transparent solution A with a concentration of 0.5mol / L;

[0030] 2) Add analytically pure thioacetamide (C 2 h 5 NS), so that the Mn in the solution 2+ / C 2 h 5 The molar ratio of NS is 1:2, and the solution is ultrasonically dispersed to obtain solution B;

[0031] 3) Pour solution B into a flask and seal it, then put the sealed flask into a three-in-one microwave, ultraviolet, and ultrasonic three-in-one synthetic extraction reaction apparatus, select the "temperature-time" working mode, set the temperature at 75°C, and the magnetic stirring speed 350r / min, add ultraviolet energy, the output power of the ultraviolet lamp is 300W, after reacting for 50min, solution C is obtained;

[0032] 4) Pour solution C into a microwave hydrothermal reactor with a filling degree of 45%, then seal the reactor, put it into a microwave hydrothermal reactor with temperature and pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com