Soil conditioner and preparation method and application thereof

A soil improver and soil technology, applied in the field of soil improver, can solve the problems of unsatisfactory decomposition effect, time-consuming and low utilization rate, so as to improve utilization rate and add economic value, prevent odor generation, and accelerate decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 The preparation process of the soil conditioner is as follows: take 100 kg of soil by crossing different soil layers from the cross section, then calcinate at 1050-1250 ° C, and naturally cool at room temperature for 8 hours to obtain the target product 95 Kilogram.

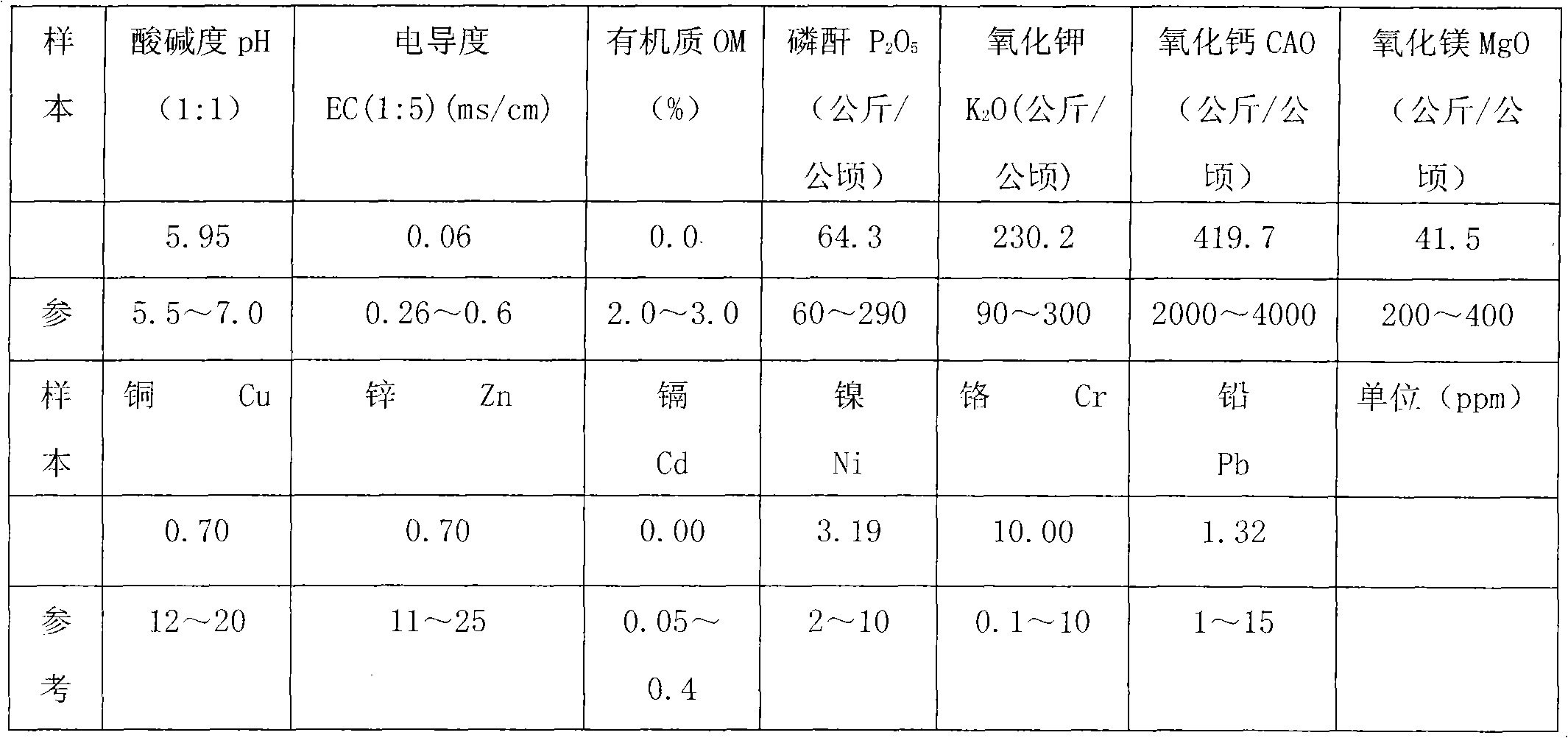

[0022] The average emissivity of far-infrared light at 3-14 μm of the soil conditioner at 50° C. is 0.869; and the fertility analysis results of the soil conditioner are shown in Table 1 below.

[0023] The characteristics of the soil conditioner are as follows:

[0024] (1) When calcined at high temperature, the original aluminum element contained in rice, sawdust and soil will disappear due to high temperature combustion, so this product is porous soil, which is obviously different from ordinary fire soil in shape and function.

[0025] (2) General brick kilns, brick kilns for firing pottery, and automatic kilns can be used for calcination, which can be mass-produced, suitable for agricultural...

Embodiment 2

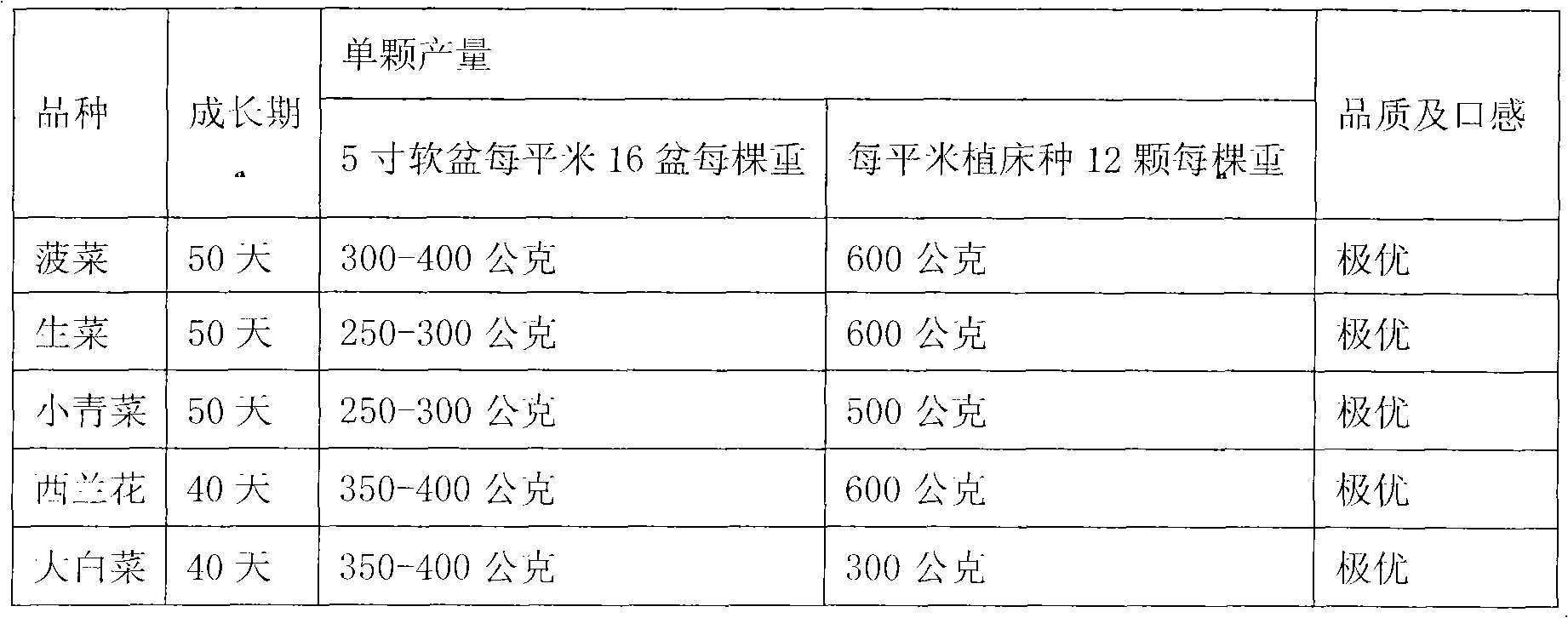

[0027] Embodiment 2 Get the soil improver obtained in the above-mentioned embodiment 1, spread it into a planting bed or a potted plant on the cement floor, and plant leafy vegetables. Under the condition of watering and no longer using topdressing, its output and quality all have excellent performances. Refer to Table 2, compared with the common soil cultivated in the same way but using chemical fertilizers or general organic fertilizers, the yield of the soil improver can be increased by more than 50%.

Embodiment 3

[0028] Embodiment 3 is used to make the soil of the soil improver described in embodiment 1 and takes place with general traditional cultivation method, and only uses this improved soil improver as base manure and topdressing in growth period, the cabbage dish produced between June, The yield is high and the quality is good, not inferior to those produced in high-cold areas, and far better than those produced in soils that have not been applied with improved soil amendments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com