Method for preparing reduced isomaltooligosaccharide

A technology of isomalto-oligosaccharide and maltitol, which is applied in the field of preparation of isomalt-oligosaccharide, can solve the problems of Maillard reaction easily, isomalto-oligosaccharide not resistant to high temperature, etc., and achieve the reduction of intestinal toxic fermentation characteristics, Promoting significant proliferation, non-digestible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

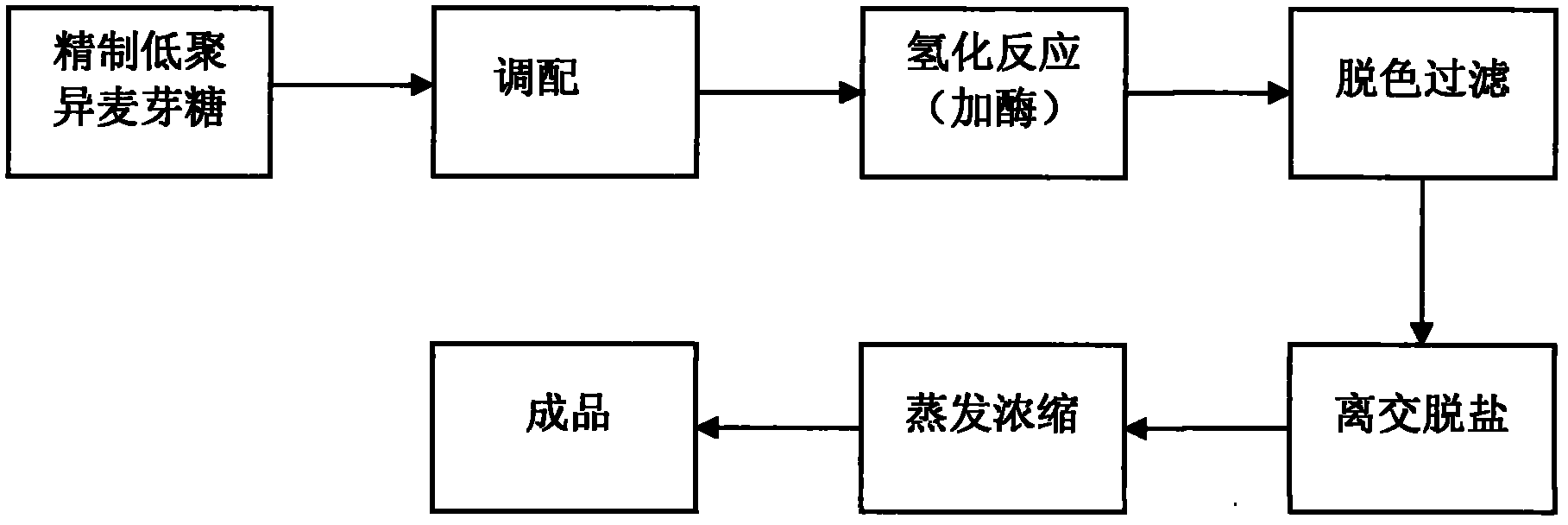

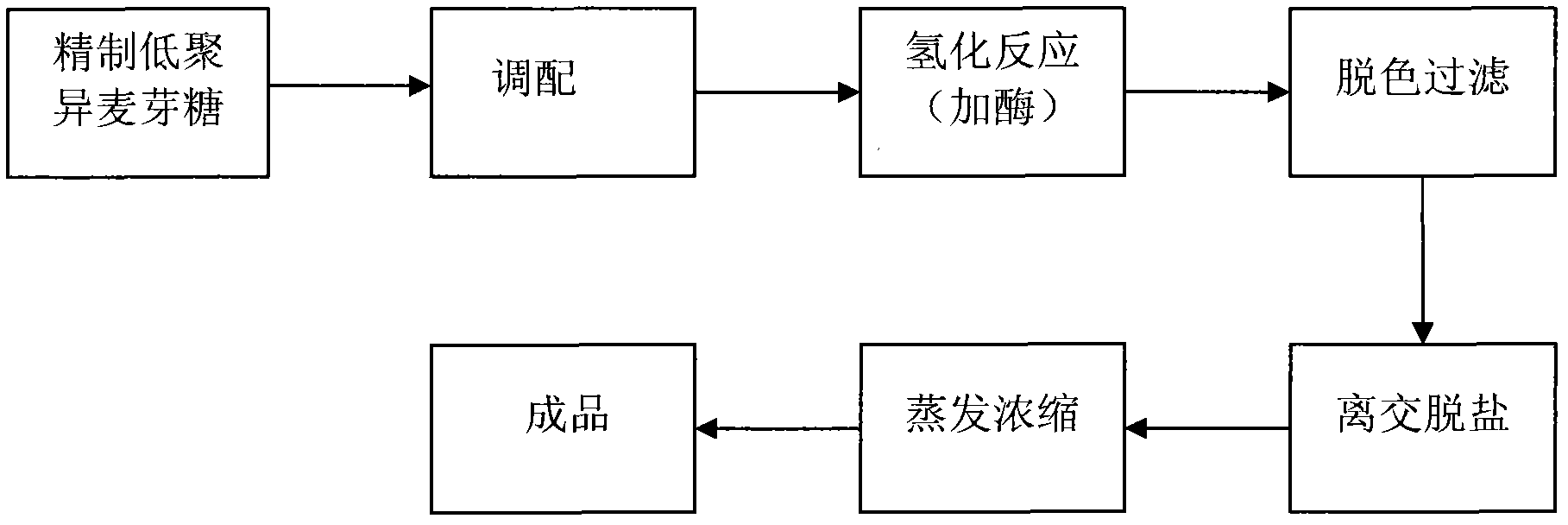

Method used

Image

Examples

Embodiment 1

[0029] Get the refined isomaltooligosaccharide syrup (DS40-50%), adjust the pH of the syrup with reagent grade sodium hydroxide to be 7.9, inject 2 / 3 volume of sugar solution in the reactor, remove the air 3 times with nitrogen, and then Exclude nitrogen with hydrogen to make the hydrogen concentration above 99%.

[0030] The solid content of the syrup is 42%, and the activated skeleton nickel catalyst is added according to 9% of the dry matter, the temperature is controlled at 136°C, the hydrogen pressure is 8.5MPa, the stirring is started, and the rotation speed is 220r / min, and hydrogen is continuously added to promote the hydrogenation reduction. After reacting for 2 hours, when the hydrogen gas was introduced and was no longer absorbed by the syrup, the reducing sugar content was measured by the 3.5-dinitrosalicylic acid colorimetric method. When the reducing sugar reached 0.2%, the reaction could be terminated, and the generated oligoiso Maltitol, after decolorization an...

Embodiment 2

[0032] Get the refined isomaltooligosaccharide syrup (DS40-50%), adjust the pH of the syrup with reagent grade sodium hydroxide to be 7.6, inject 2 / 3 volume of sugar solution in the reactor, remove the air 3 times with nitrogen, and then Exclude nitrogen with hydrogen to make the hydrogen concentration above 99%.

[0033] The solid content of the syrup is 45%, and the activated skeleton nickel catalyst is added according to the dry matter amount of 9.2%. The temperature is controlled at 135°C, the hydrogen pressure is 8.8MPa, the stirring is started, and the rotation speed is 230r / min, and hydrogenation is continuously added to promote the hydrogenation reduction. Reacted for 2.4 hours, when the hydrogen gas was introduced and was no longer absorbed by the syrup, the reducing sugar content was measured by the 3.5-dinitrosalicylic acid colorimetric method. When the reducing sugar reached 0.2%, the reaction could be terminated, and the generated oligomeric iso Maltitol, after de...

Embodiment 3

[0035] Get the refined isomaltooligosaccharide syrup (DS40-50%), adjust the pH of the syrup with reagent grade sodium hydroxide to be 7.7, inject 2 / 3 volume of sugar solution in the reactor, remove the air 3 times with nitrogen, and then Exclude nitrogen with hydrogen to make the hydrogen concentration above 99%.

[0036] The solid content of the syrup is 46%, and the activated skeleton nickel catalyst is added according to 9.4% of the dry matter, the temperature is controlled at 137°C, the hydrogen pressure is 9MPa, the stirring is started, and the rotation speed is 240r / min, and hydrogen is continuously added to promote hydrogenation reduction. After 2.6 hours, when the hydrogen is no longer absorbed by the syrup, use the 3.5-dinitrosalicylic acid colorimetric method to measure the reducing sugar content. When the reducing sugar reaches 0.2%, the reaction can be terminated, and the generated isomaltooligosaccharide Alcohol, after decolorization and filtration, separation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com