Water-soluble polysaccharide extracted from black fungus and preparation method thereof

A technology of water-soluble polysaccharide and black fungus is applied in the fields of natural macromolecules and food to achieve the effects of low cost, improved immunity and easy gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

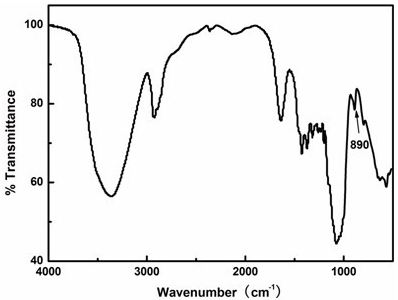

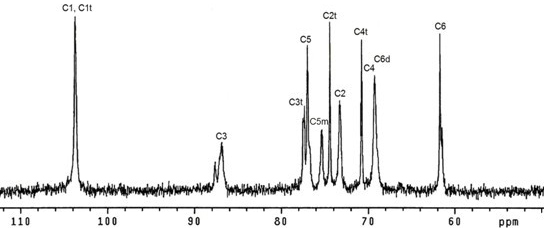

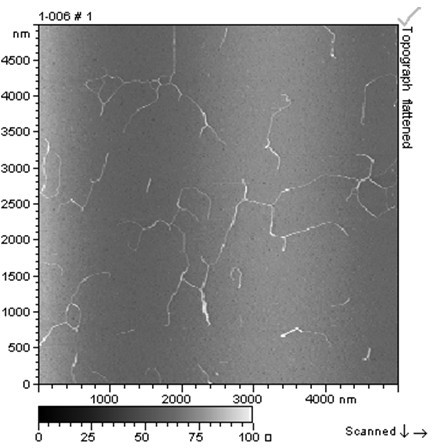

[0020] Purchase commercially available black fungus fruiting bodies from Fang County, Hubei Province, degrease the dried black fungus fragments with ethyl acetate and acetone for 4 hours, and then soak the dried fragments in a mixed solvent of ethanol / water with a volume ratio of 70 / 30 overnight. Separate the residue, soak in 0.9wt% NaCl aqueous solution, stir at 100°C for 2-4 hours, then continue to stir at room temperature for 20-22 hours, centrifuge, collect the supernatant, repeat this step three times; 30wt%H 2 o 2 Decolorize to light yellow, remove free protein with Sevag method, this method is based on the characteristics of protein denaturation in organic solvents such as chloroform, mix chloroform and n-butanol mixture (its volume ratio is 5: 1) with polysaccharide solution, vigorously After shaking for 20 minutes, centrifuge to remove the denatured protein at the junction of the water layer and the solvent layer. Repeat 6-10 times until there is no protein absorpt...

Embodiment 2

[0034] Purchase commercially available black fungus fruiting bodies produced in Fang County, Hubei Province, perform Soxhlet extraction on the dried black fungus fragments with ethyl acetate and acetone for 4 hours each, and then soak in 70vol% ethanol aqueous solution overnight. The residue was extracted with 0.9% NaCl aqueous solution at 70°C for 2-4 hours, then extracted at room temperature until 20-22 hours, centrifuged, and the supernatant was collected. This step was repeated three times; the supernatant was extracted with 30wt% H 2 o 2Decolorize to light yellow, remove free protein by Sevag method, repeat 6-10 times until there is no protein absorption peak at 280nm by UV detection. Then, tap water and distilled water were respectively dialyzed through a regenerated cellulose membrane dialysis bag (Mw cut-off8000, Union Carbide, NJ, USA) for 5 days and 3 days, concentrated, and freeze-dried to obtain black fungus crude polysaccharide. This crude polysaccharide contains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Zero shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com