Quantum dot/polymer composite nitric oxide fluorescent probe and preparation method thereof

A technology of nitric oxide and fluorescent probes, which is applied in the field of analysis and detection, can solve the problems that have not yet been reported on the research of composite nitric oxide fluorescent probes, and cannot solve the problems of quantum dot dispersion, poorness and agglomeration, and achieve stable fluorescence Long time, easy to popularize and apply, and quickly detect the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

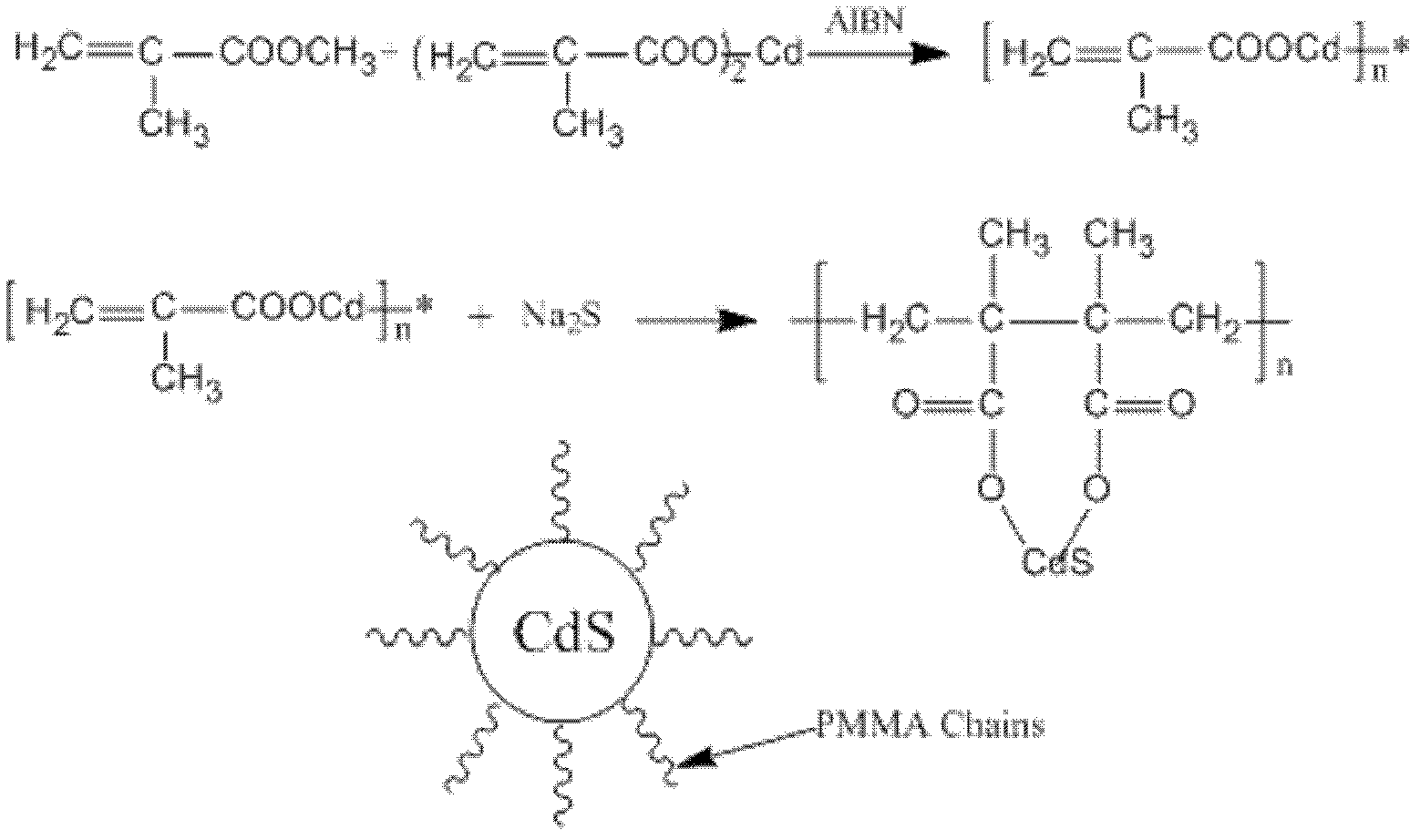

[0032] Weigh 0.1387g of cadmium acetate (C 4 h 6 CdO 4 2H 2 O) 0.00052 and 0.038g of azobisisobutyronitrile were dissolved in a three-necked flask filled with 8ml of methyl methacrylate and 1ml of methacrylic acid, stirred under nitrogen protection, and heated to 70~90°C for prepolymerization , observe the viscosity of the system during the prepolymerization process, and stop heating immediately when the viscosity of the prepolymer is close to the viscosity of glycerin;

[0033] Weigh 0.15g of sodium sulfide (Na 2 S·9H 2 O) Dissolve in 1.5mL of deionized water, add it dropwise to a three-necked flask, and simultaneously with vigorous stirring, the mixture quickly turns bright yellow;

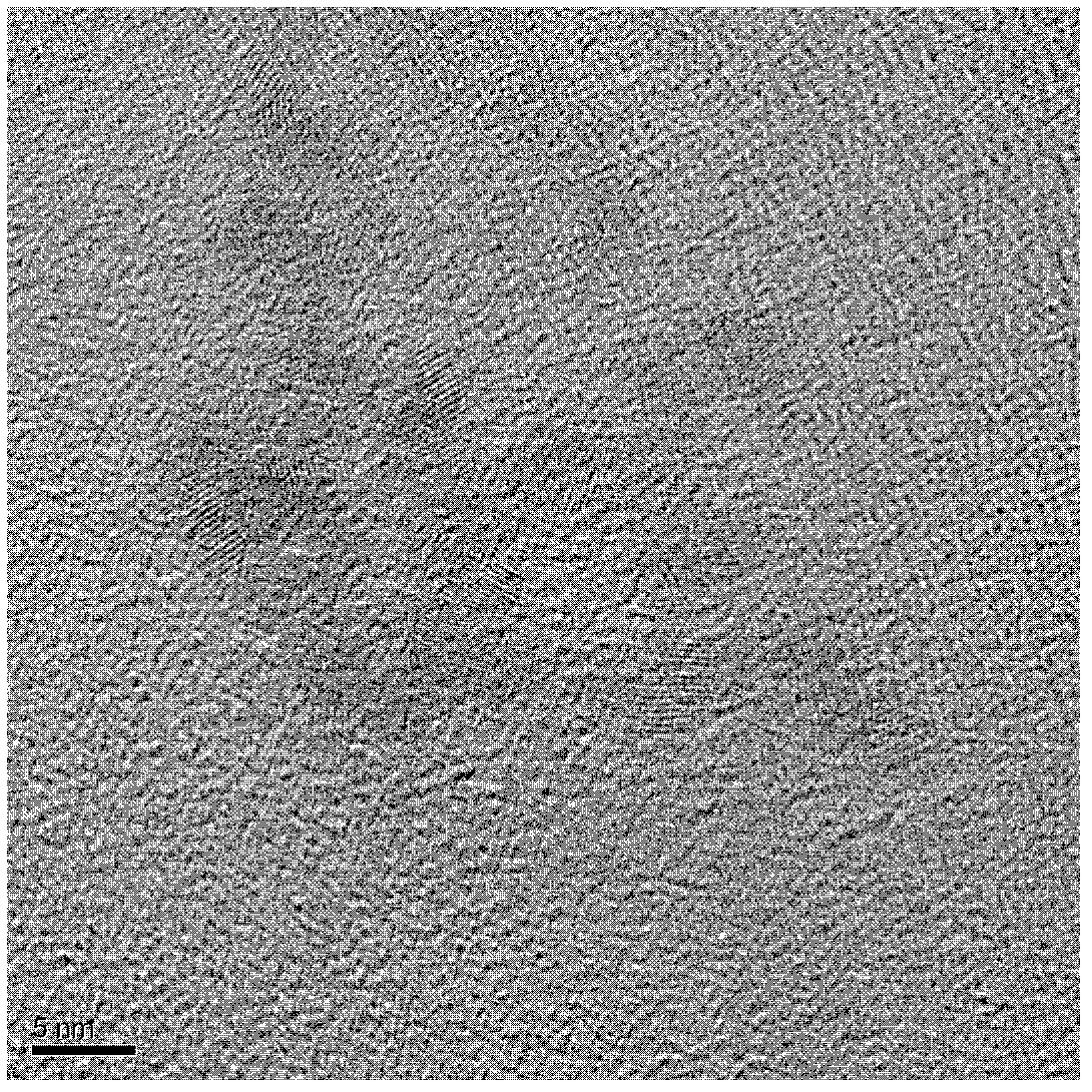

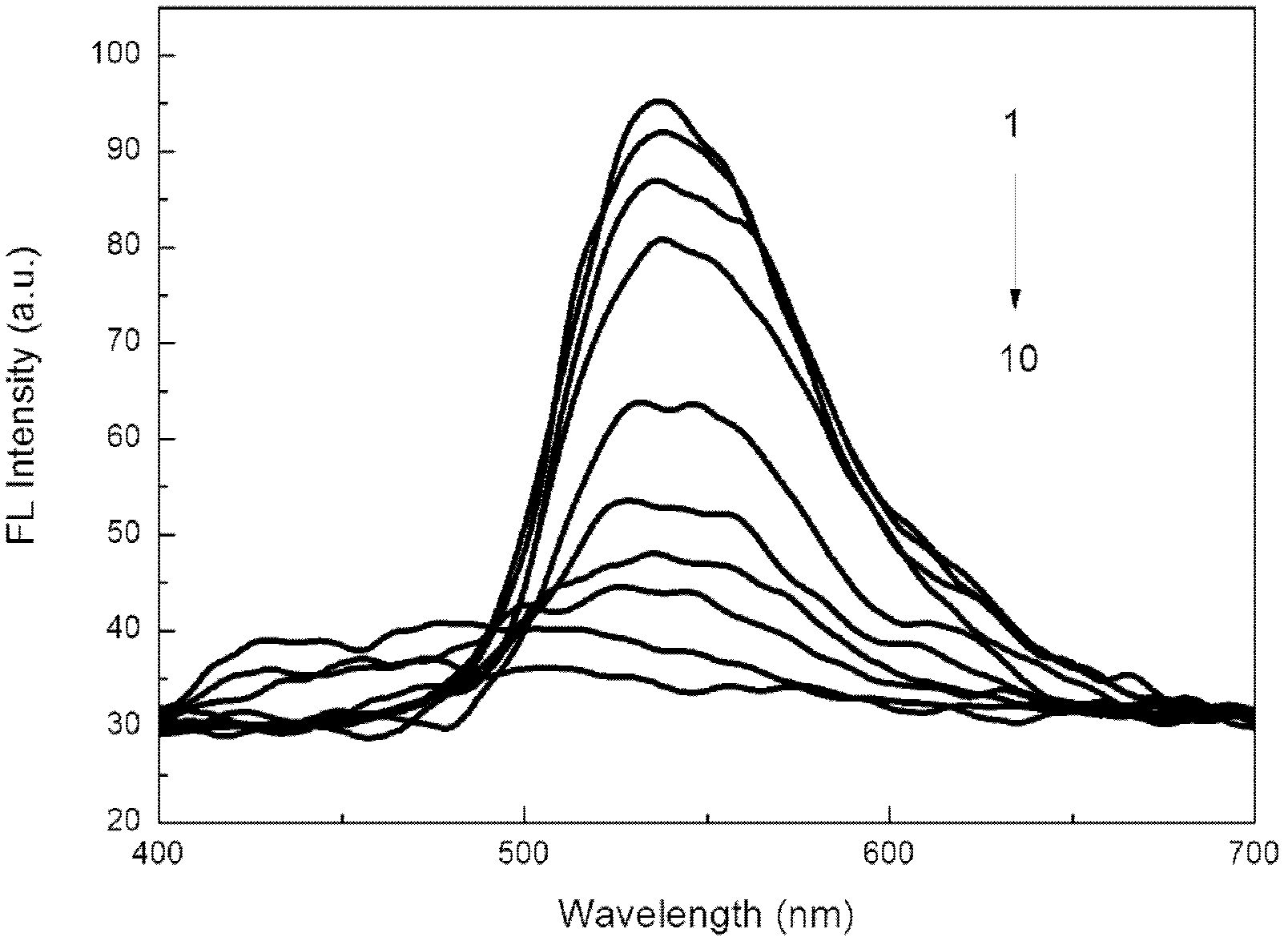

[0034] Transfer the mixture to a one-necked flask, put it in an oven, and polymerize at 60°C for 20 hours to obtain a CdS / PMMA composite nitric oxide fluorescent probe, see figure 1 . The CdS / PMMA composite NO fluorescent probe is shown in figure 2 . Depend on figure 2 It can be obta...

Embodiment 2

[0039] Example 2 is the same as Example 1, except that in step (2) of Example 1, "weigh 0.15g of sodium sulfide and dissolve it in 1.5mL of deionized water" is replaced by "weigh 0.164g Na 2 SeO 3 ·5H 2 O, 0.8 g NaOH and 3 mL N 2 h 4 ·H 2 O dissolved in 5mL deionized water"; the "polymerization at 60°C for 20h" in step (3) of Example 1 was replaced with "polymerization at 50°C for 12h" to obtain a CdSe / PMMA composite nitric oxide fluorescent probe. It was tested by TEM : CdSe is evenly distributed in the matrix material PMMA, and the spherical nanoparticles with a size of CdSe between about 5nm.

Embodiment 3

[0041] Example 3 is the same as Example 1, except that in step (2) of Example 1, "weigh 0.15 g of sodium sulfide and dissolve it in 1.5 mL of deionized water" is replaced by "5 mL of freshly prepared sodium hydride telluride (NaHTe) solution ", replace the "polymerization at 60°C for 20h" in step (3) of Example 1 with "polymerization at 70°C for 15h" to obtain a CdTe / PMMA composite nitric oxide fluorescent probe. The TEM test shows that: CdTe is evenly distributed in the matrix material PMMA, and the CdTe is spherical nanoparticles with a size of about 5 nm.

[0042] Preparation of NaHTe solution: take 79.75 mg Te powder, 56.7 mg NaBH 4 Add 5ml of deoxygenated ultrapure water into a flask filled with nitrogen, and heat it to about 70~90°C under constant stirring, and bubbles can be observed. The reaction was completed when no obvious bubbles emerged, and the pink solution obtained at this time was the NaHTe solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com