Yb3+-doped vanadate up-conversion fluorescent material and preparation method thereof

A fluorescent material and vanadate technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that vanadate has not been reported in the literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

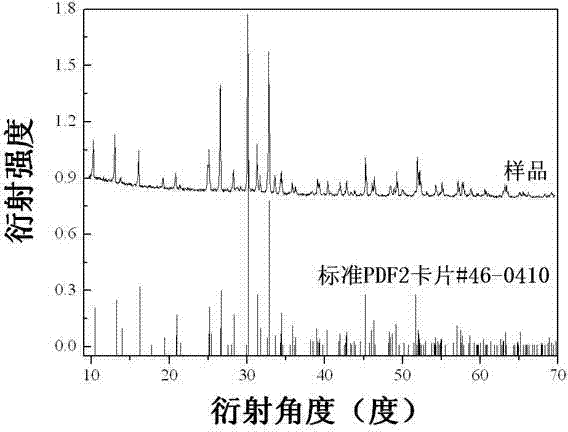

[0030] Preparation of upconversion luminescent material Ca 9 La 0.9 Yb 0.1 (VO 4 ) 7

[0031] Weigh calcium carbonate CaCO 3 : 4.5041 g, lanthanum oxide La 2 o 3 : 0.7331 g, ytterbium oxide Yb 2 o 3 : 0.1 g, and ammonium vanadate NH 4 VO 3 : 4.0943 grams, ground in an agate mortar and mixed evenly, select the air atmosphere for the first calcination, the temperature is 300 ℃, the calcination time is 3 hours, then cool to room temperature, take out the sample. After the first calcination of the raw materials, the mixture is fully mixed and ground again, and then sintered for the second time at 630°C in an air atmosphere. The sintering time is 5 hours, and cooled to room temperature; again, the mixture is fully mixed and ground evenly , in the air atmosphere, the third sintering at 1000 ° C, the sintering time is 6 hours, cooled to room temperature; that is, powdery Yb 3+ Doped rare earth calcium vanadate based up-conversion fluorescent material.

[0032] See attach...

Embodiment 2

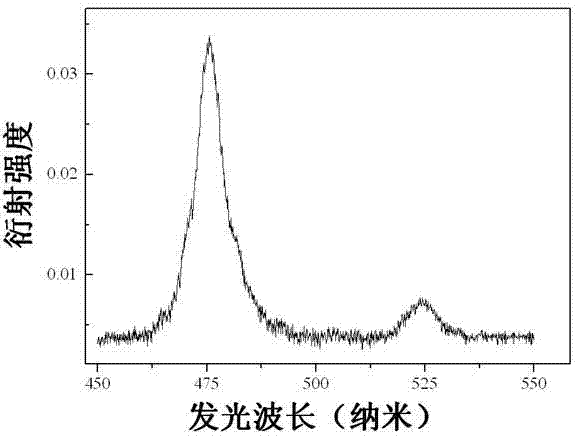

[0035] Preparation of upconversion luminescent material Ca 9 La 0.2 Yb 0.8 (VO 4 ) 7

[0036] Weigh calcium carbonate CaCO 3 : 4.5041 g, lanthanum oxide La 2 o 3 : 0.163 g, ytterbium oxide Yb 2 o 3 : 0.7882 g, and ammonium vanadate NH 4 VO 3 : 4.0943 grams, ground in an agate mortar and mixed evenly, select the air atmosphere for the first calcining, the temperature is 450 ℃, the calcining time is 5 hours, then cool to room temperature, take out the sample. After the raw material calcined for the first time, the mixture is fully mixed and ground again, and then sintered for the second time at 950°C in the air atmosphere. The sintering time is 10 hours, and cooled to room temperature; that is, powdery Yb is obtained. 3+ Doped rare earth calcium vanadate based up-conversion fluorescent material.

[0037] See attached image 3 , which is the up-conversion luminescence spectrum diagram of the sample prepared according to the technical scheme of this embodiment under t...

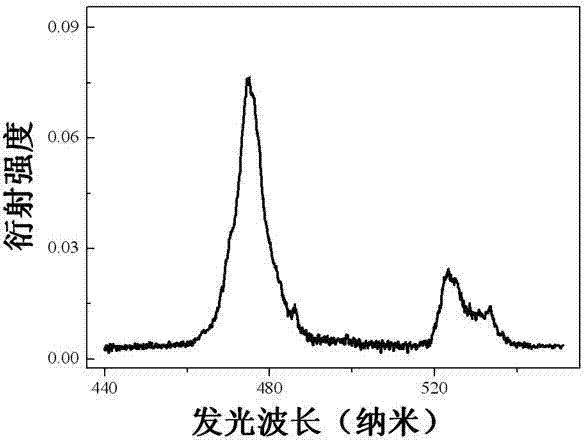

Embodiment 3

[0039] Preparation of upconversion luminescent material Ca 9 Gd 0.2 Yb 0.8 (VO 4 ) 7

[0040] Weigh calcium carbonate CaCO 3 : 4.5041 g, gadolinium oxide Gd 2 o 3 : 0.1813 g, ytterbium oxide Yb 2 o 3 : 0.7882 g, and ammonium vanadate NH 4 VO 3 : 4.0943 grams, after grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first calcination, the temperature is 500 ° C, the calcination time is 6 hours, then cooled to room temperature, and the sample is taken out. Mix and grind the mixture thoroughly again, and sinter for the second time at 1050°C in an air atmosphere. The sintering time is 7 hours, and cooled to room temperature; that is, powdery Yb is obtained. 3+ Doped rare earth calcium vanadate based up-conversion fluorescent material. The up-conversion luminescence spectrum of the sample prepared by the technical scheme of this embodiment is similar to that of Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com