Photon stimulated cell desorption method and cell culture implement used by same

A cell culture and in vitro cell culture technology, applied in the field of tissue engineering, can solve the problems of damaged cells and long time, and achieve the effects of small cell damage, high efficiency and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

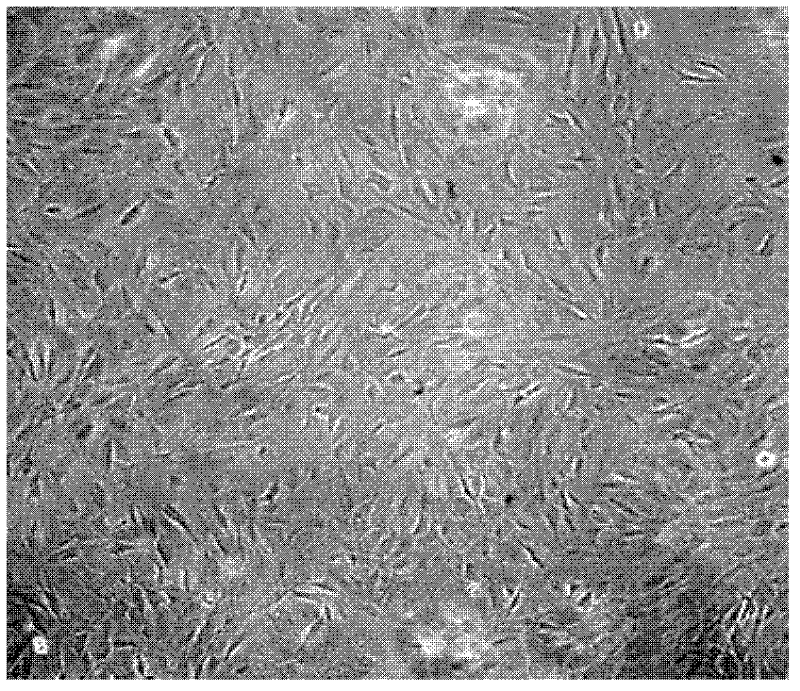

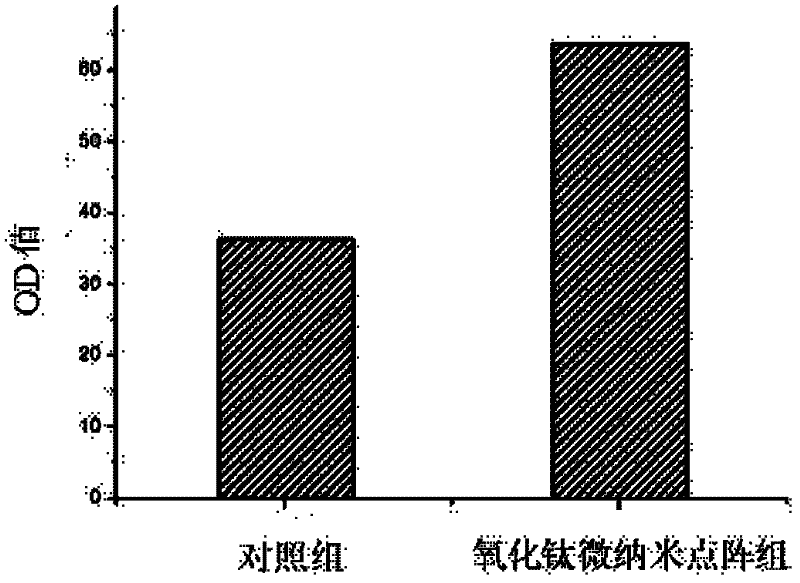

[0029] Titanium oxide micro-nano lattices were prepared on the cell contact surface of quartz glass cell culture vessels by phase-splitting self-assembly method, the process is as follows: according to the preparation of ethanol: deionized water: acetylacetone = 0.3: 1: 1 (in molar ratio) solution, and add tetra-n-butyl titanate by 0.02mol / L, and add polyvinylpyrrolidone (K-30) by 40g / L to form a precursor solution, which is added dropwise on the cell contact surface of the quartz glass cell culture vessel, Spin coating at a speed of 6000 rpm for 40 s, and then heat-treat at 500 °C for two hours to obtain titanium oxide micro-nano lattices as a cell culture surface. The density of nano-dots in the titanium oxide micro-nano lattice is 1.0×10 10 / cm 2 , The dot size is 200nm ~ 500nm.

[0030] Bone cells were cultured in vitro on the cell culture surface of the above-mentioned quartz glass cell culture vessel. After three days of culture, ultraviolet light with a wavelength of ...

Embodiment 2

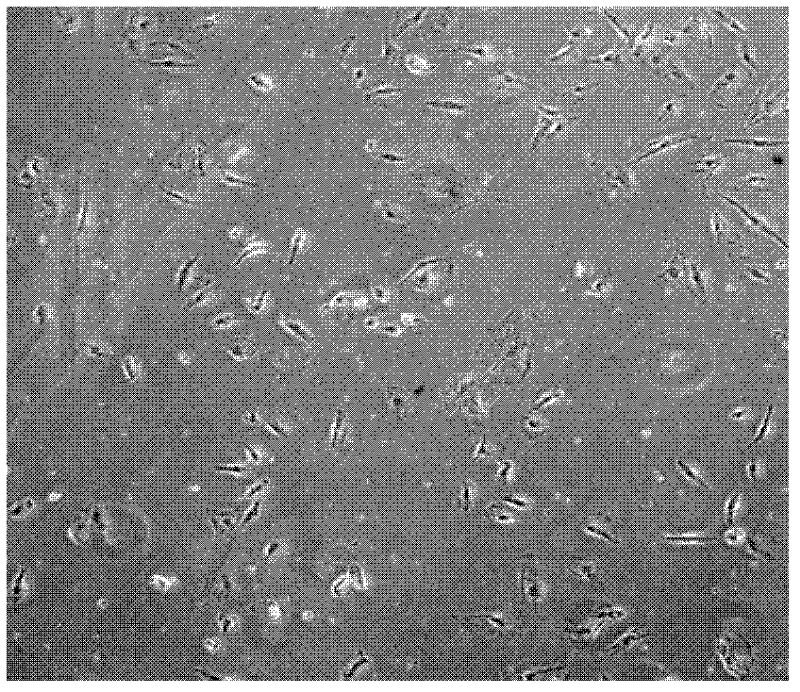

[0036] A zinc oxide thin film is prepared on the cell contact surface of a silicate glass cell culture vessel by a chemical vapor deposition method as a cell culture surface, the grain size of the zinc oxide thin film is 2-10nm, and the thickness is 50nm.

[0037] Fibroblasts were cultured in vitro on the cell culture surface of the above-mentioned silicate glass cell culture vessel. After culturing for three days, ultraviolet light with a wavelength of 300 nanometers was incident from the bottom of the cell culture vessel and irradiated for 1 minute to make 70% of the cells from Surface detachment.

Embodiment 3

[0039] A titanium oxide thin film is prepared on the cell contact surface of the polylactic acid cell culture vessel by a physical vapor deposition method as the cell culture surface, the grain size of the titanium oxide thin film is 10-30nm, and the thickness is 1000nm.

[0040] Fibroblasts were cultured in vitro on the cell culture surface of the above-mentioned polylactic acid cell culture vessel. After three days of culture, ultraviolet light with a wavelength of 365 nanometers was incident from the bottom of the cell culture vessel and irradiated for 25 minutes to detach 74% of the cells from the surface. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com