Method for preparing carbon-coated spherical nano lithium iron phosphate by liquid phase method

A lithium iron phosphate, nanotechnology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of complex process and long precursor processing time, achieve uniform particle size, excellent high-current discharge performance, and improve tap density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

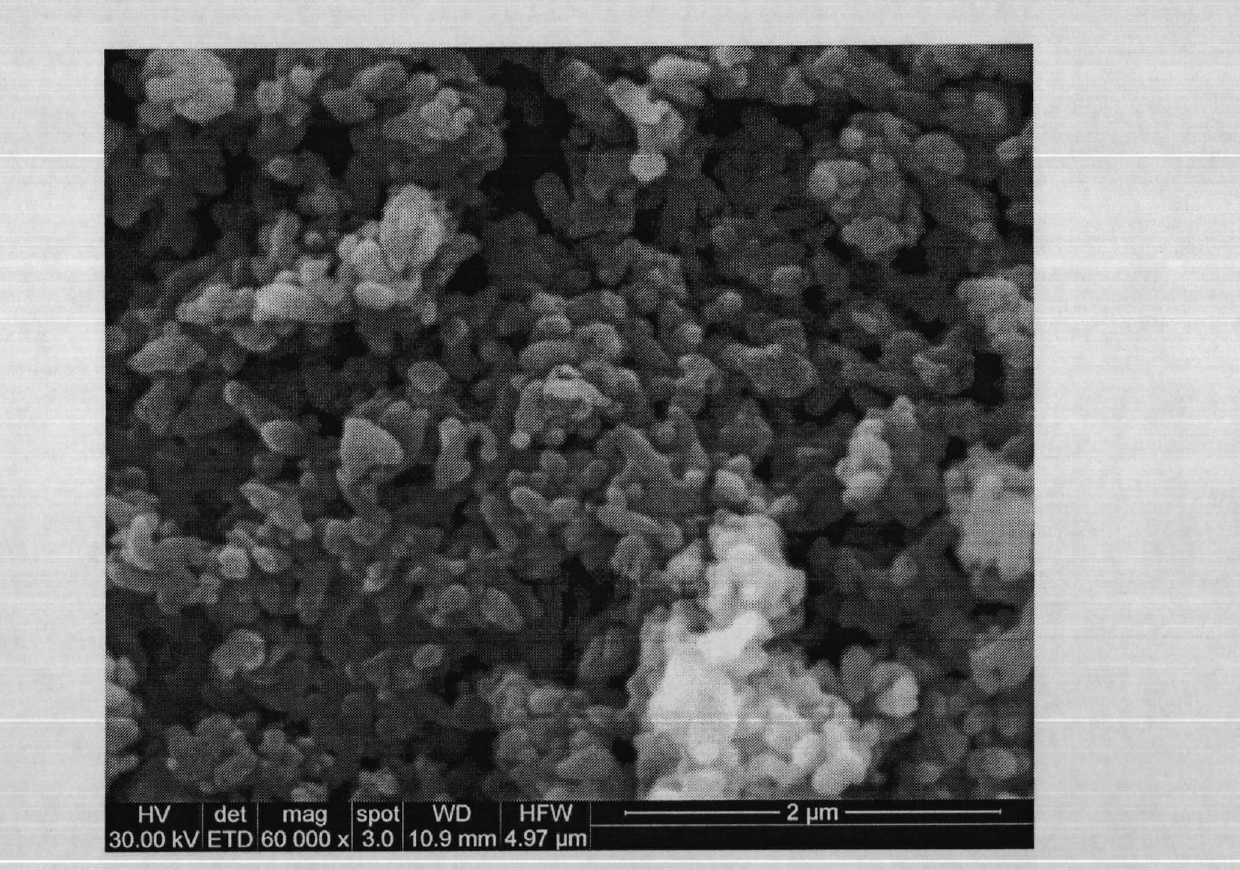

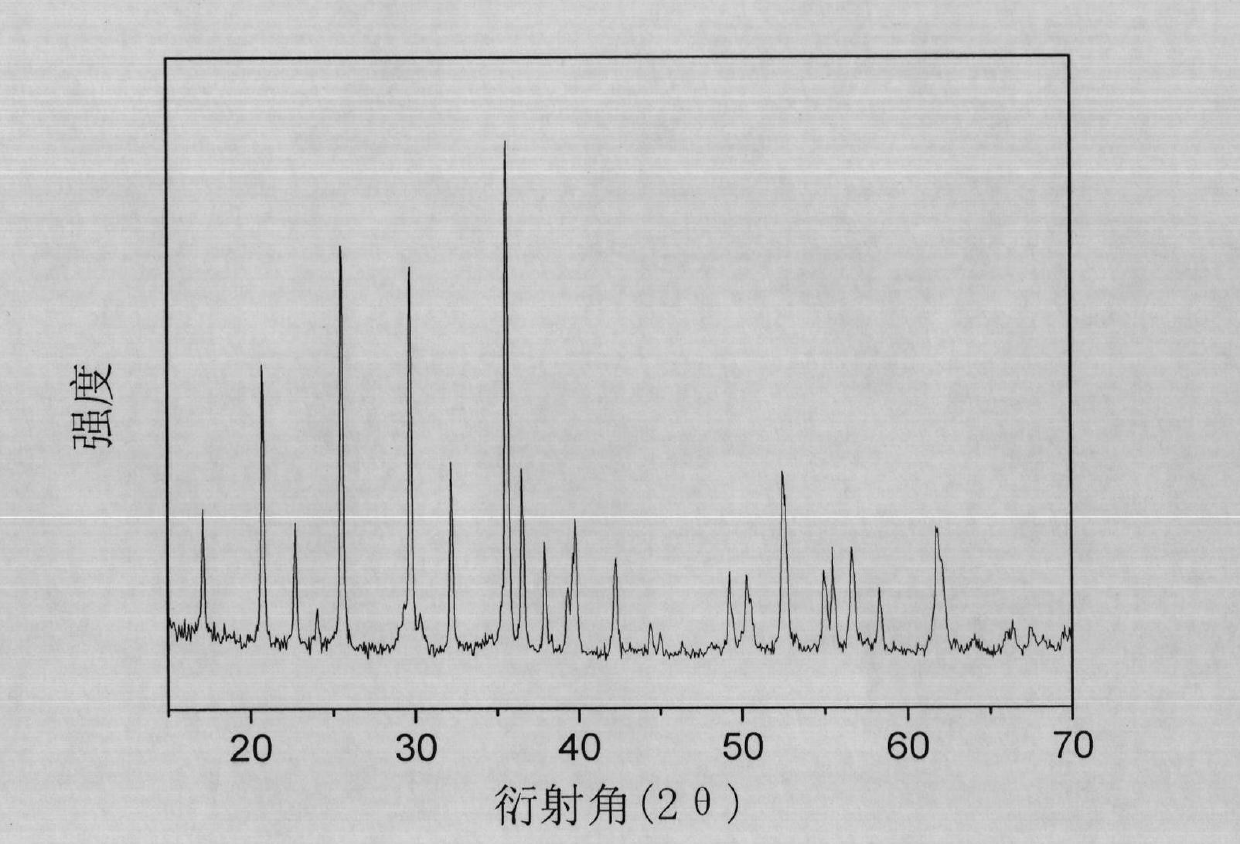

[0023] Prepare 1mol.L according to Fe:P molar ratio of 1:1 -1 100ml of mixed aqueous solution of ferrous sulfate and phosphoric acid, put the mixed solution in a 500ml reaction vessel with a reflux condenser device, add 100ml of dimethyl sulfoxide and 10ml of 2% polyacrylamide solution successively, slowly add 3mol .L -1 Lithium hydroxide solution until the pH of the reaction solution was 7, then heated to the boiling point of the solution (108°C) for 2 hours, the product was filtered, washed with deionized water and absolute ethanol, and dried in vacuum at 100°C for 10 hours to obtain pure phase nano-lithium iron phosphate powder. The obtained powder is mixed with 20% glucose and placed in a tube furnace, carbonized and spheroidized at 600° C. for 3 hours under the protection of nitrogen, and the product of the present invention is obtained after cooling. The obtained product has a spherical appearance and a particle size of 50-200 nm ( figure 1 ), detected by XRD powder di...

example 2

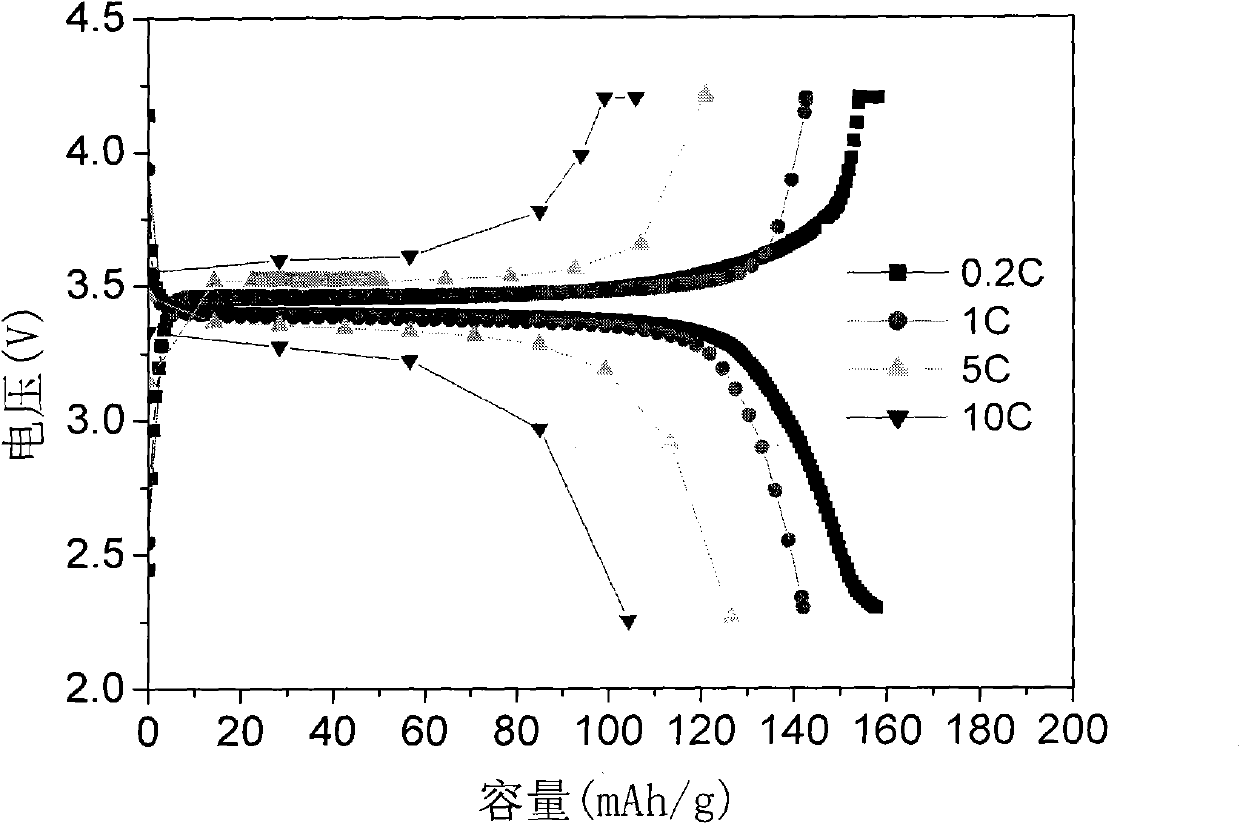

[0026] Prepare 1mol.L according to Fe:P molar ratio of 1:1 -1100ml of mixed aqueous solution of ferrous sulfate and phosphoric acid, put the mixed solution in a 500ml reaction vessel with a reflux condenser device, add 200ml of dimethyl sulfoxide and 1g of sodium dodecylbenzenesulfonate successively, and slowly add 2mol.L -1 Lithium hydroxide solution until the pH of the reaction solution is 7, then heated to the boiling point of the solution (115°C) and reacted for 1 hour, the product was filtered, washed with deionized water and absolute ethanol, and dried in vacuum at 100°C for 10 hours to obtain nano Lithium iron phosphate powder, mix the obtained nano-powder with 15% sucrose and place it in a tube furnace at 95N 2 and 5%H 2 Under the protection of mixed gas, crystallize at a high temperature of 600°C for 2 hours, cool and pulverize to obtain the product of the present invention. The shape of the obtained sample is spherical, and the particle size is 80-250nm. 1C and 1...

example 3

[0028] Prepare 1mol.L according to Fe:P molar ratio of 1:1 -1 100ml of mixed aqueous solution of ferrous chloride and phosphoric acid, put the mixed solution in a 500ml reaction vessel with a reflux condenser device, add 100ml of ethylene glycol and 0.5g of cetyltrimethylammonium bromide successively, stir slowly Slowly add 2mol.L -1 Lithium hydroxide solution until the pH of the reaction solution is 6.5, then heated to the boiling point of the solution (106°C) for 2 hours, the product was filtered, washed with deionized water and absolute ethanol, and dried in vacuum at 100°C for 10 hours to obtain nano Lithium iron phosphate powder. The resulting nanopowder was mixed with 10% glucose and placed in a tube furnace at 95N 2 and 5%H 2 Under the protection of mixed gas, carbonize and spheroidize at 550°C for 3 hours, cool and pulverize to obtain the product of the present invention. The shape of the obtained sample is spherical, the particle size is 50-200nm, and the sample i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com