Nanometer vanadyl phosphate as well as preparation method and application thereof

A vanadyl phosphate and nano-technology, applied in the field of nano-materials, can solve the problems of carbon deposition on the catalyst surface, reduced catalyst activity, excessive oxidation of raw materials, etc., and achieve the effects of small size, improved reactivity, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

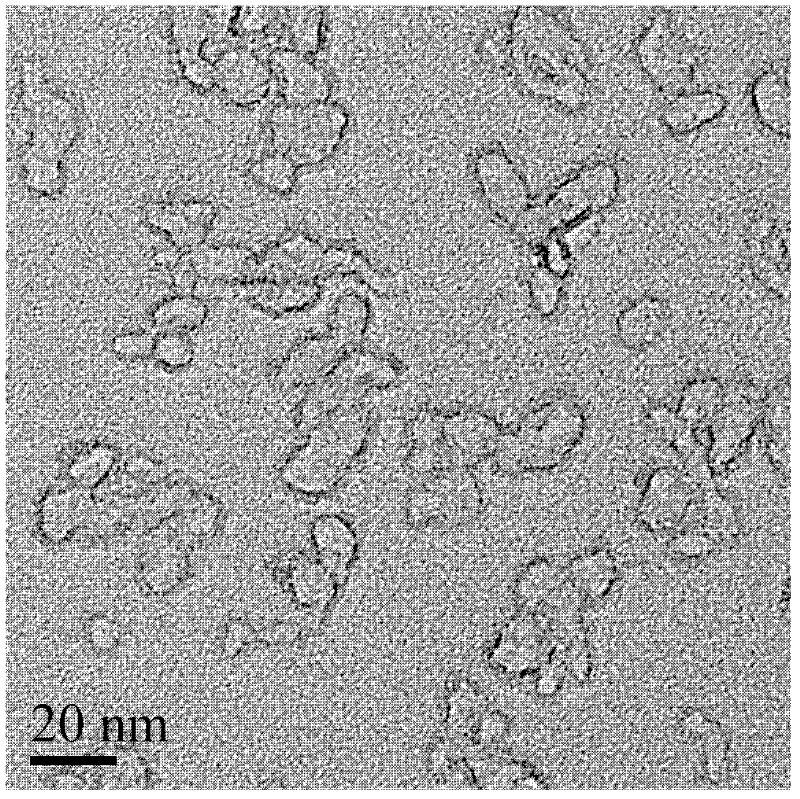

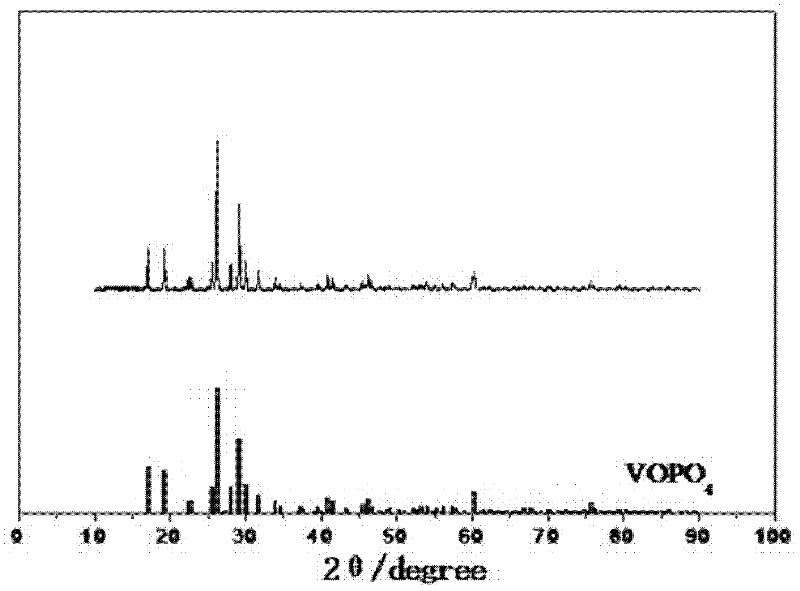

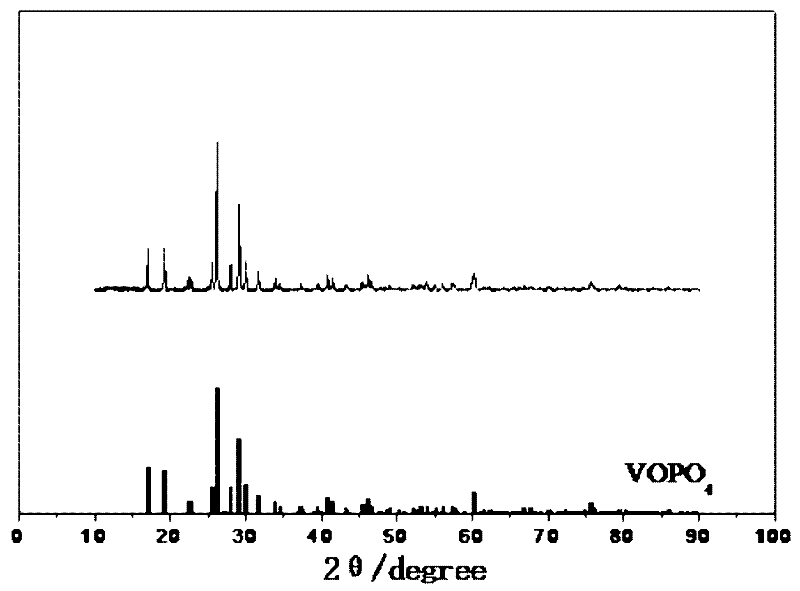

Embodiment 1

[0023] Weigh out the V of 1.0 2 o 5 and 0.54 g of H 3 PO 4 Put it in a 25ml hydrothermal reactor with a Teflon lining, add 18ml of methanol and mix well; after sealing, put the hydrothermal reactor into a resistance furnace and heat it to 180°C, using its own pressure to keep the temperature constant Hydrothermal treatment for 24 hours; after the reaction, the reaction kettle was naturally cooled to room temperature; the blue-green product in the reaction kettle was separated by suction filtration and washed repeatedly with distilled water and ethanol respectively, and then placed in vacuum drying at 60°C for 4 hours to obtain the vanadyl phosphate precursor The precursor is calcined at 600°C in a nitrogen atmosphere in a resistance furnace for 2 hours, and cooled to room temperature to obtain nano-β-phase vanadyl phosphate in a granular hollow structure, with a particle size of 10-20nm and a wall thickness of 1-3nm.

Embodiment 2

[0025] According to the molar ratio of vanadium to phosphorus of 1:1, the total mass of 2.2g of V 2 o 4 and P 2 o 5 Put it in a 100ml hydrothermal reaction kettle, add 50ml of glycerol and 30ml of distilled water and mix well. After sealing, put the reaction kettle into a resistance furnace and heat it to 280°C. After constant temperature reaction for 2 hours, cool naturally to room temperature. Filter the product in the reaction kettle and wash it repeatedly with distilled water and ethanol respectively, then dry it in vacuum at 60°C for 5h to obtain the vanadyl phosphate precursor, calcinate the precursor in a resistance furnace at 700°C for 3h, cool to room temperature, and obtain granular Nano β-phase vanadyl phosphate with a hollow structure, the particle size is 20-30nm, and the wall thickness is 2-5nm.

Embodiment 3

[0027] According to the molar ratio of vanadium to phosphorus of 1:1, the V 2 o 3 and (NH 4 ) 3 PO 4 Place in a 100ml autoclave, then add 20ml of acetaldehyde, 20ml of ethanol and 40ml of distilled water and mix well. After sealing, put the reaction kettle into a resistance furnace and heat it to 120°C. After constant temperature reaction for 200h, naturally cool to room temperature. Filter the product in the reaction kettle and wash it repeatedly with distilled water and ethanol respectively, then dry it in vacuum at 60°C for 5 hours to obtain the vanadyl phosphate precursor, which is calcined in a resistance furnace at 400°C for 8 hours, and cooled to room temperature to obtain a granular Nano β-phase vanadyl phosphate with a hollow structure, the particle size is 10-30nm, and the wall thickness is 1-4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com