Method for preparing bioactive composite film layer containing hydroxyapatite on titanium metal surface

A technology of hydroxyapatite and composite film, which is applied in the medical field, can solve the problems of low HA content in the film layer, complicated preparation process, and reduced bonding force of the film base, and achieves simple method, simplified process, and good film bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

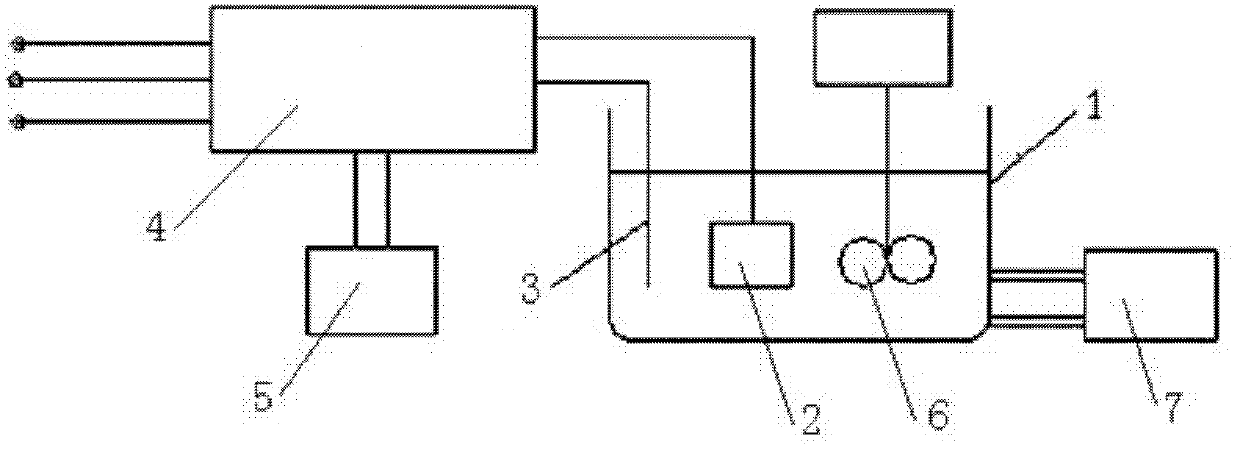

[0035] The method for preparing a biologically active composite film layer containing hydroxyapatite on the surface of titanium metal, the specific operations are as follows:

[0036] Step 1, prepare the electrolytic solution in the oxidation tank:

[0037] Mix the calcium glycerophosphate with a concentration of 4g / L and the calcium acetate with a concentration of 25g / L to obtain a mixture A, and the solvent in the mixed solution A is distilled water; then add sodium hydroxide to the mixture A to adjust its pH to 11 , to obtain a mixed solution B; finally add hydroxyapatite to the mixture B in an amount of 12g / L to obtain an electrolyte solution;

[0038] Step 2,

[0039] First surface treatment of pure titanium (purity 99.9%): first polished, then cleaned and degreased;

[0040] Then put the titanium metal sample into the electrolytic solution prepared in step 1, connect the titanium metal sample to the positive pole of the power supply, connect the stainless steel plate t...

Embodiment 2

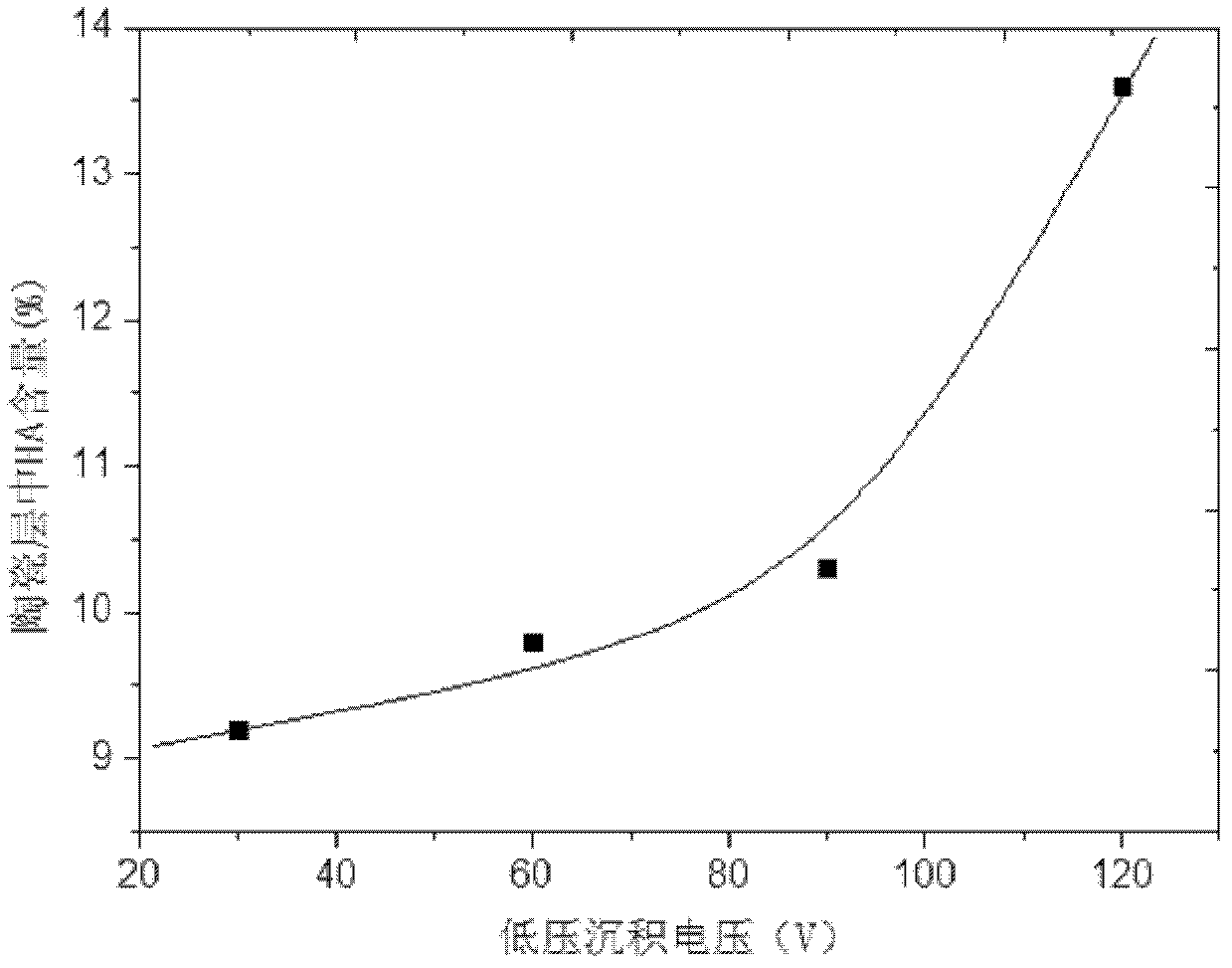

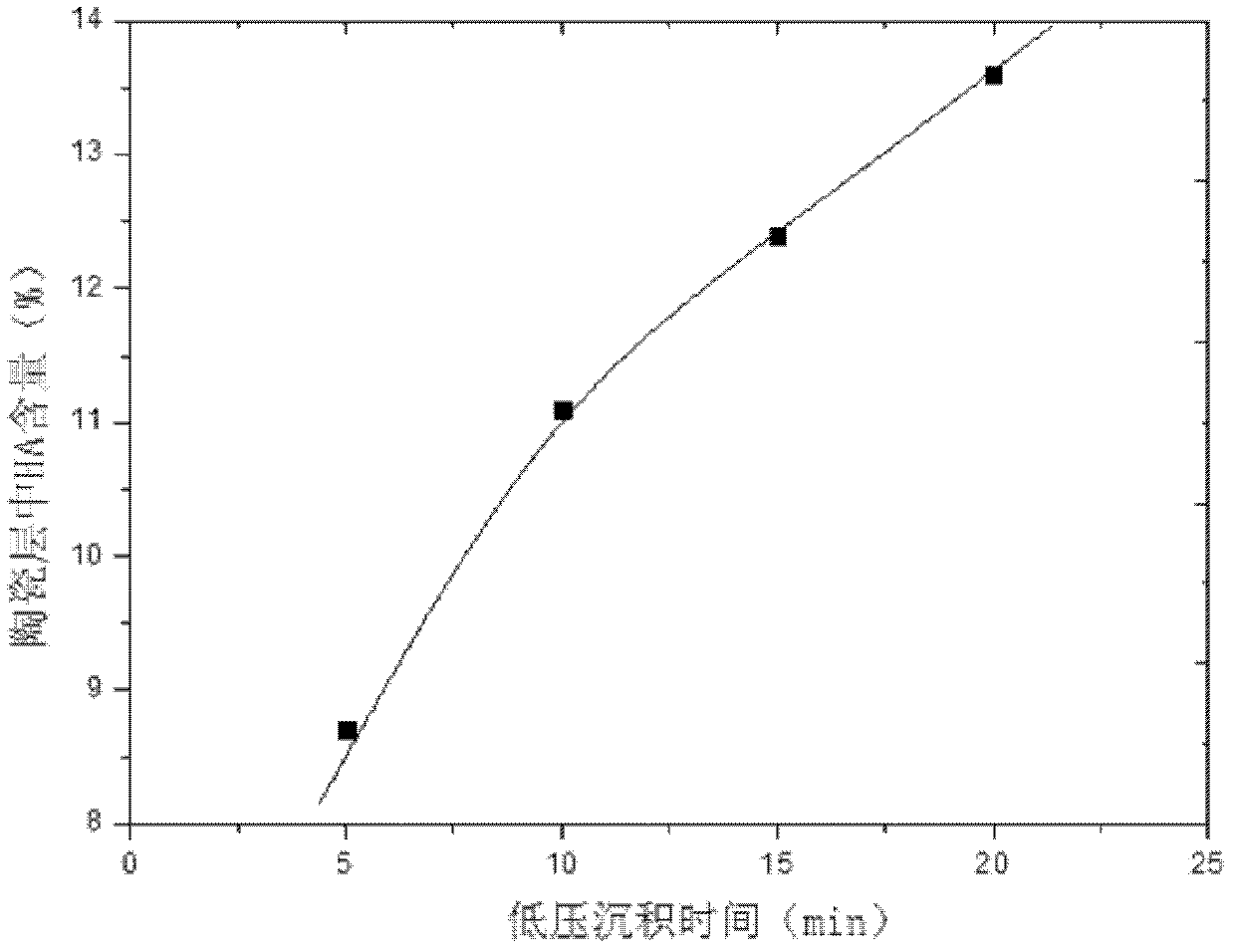

[0046]The difference from Embodiment 1 is that only the control voltage of the low-voltage deposition stage is different, the voltage is 90V, and the rest are the same as Embodiment 1.

[0047] After testing, HA-TiO 2 The HA content in the composite ceramic layer is 10.3%.

Embodiment 3

[0049] The difference from Embodiment 1 is that only the control voltage of the low-voltage deposition stage is different, the voltage is 60V, and the rest are the same as Embodiment 1.

[0050] After testing, HA-TiO 2 The HA content in the composite ceramic layer was 9.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com