A carbon microsphere as a transition layer titanium carbide in-situ growth cnts three-dimensional composite material and its preparation method

A composite material and in-situ growth technology, applied to structural parts, electrical components, battery electrodes, etc., can solve the problem of high price, achieve low equipment requirements, realize industrialized mass production, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

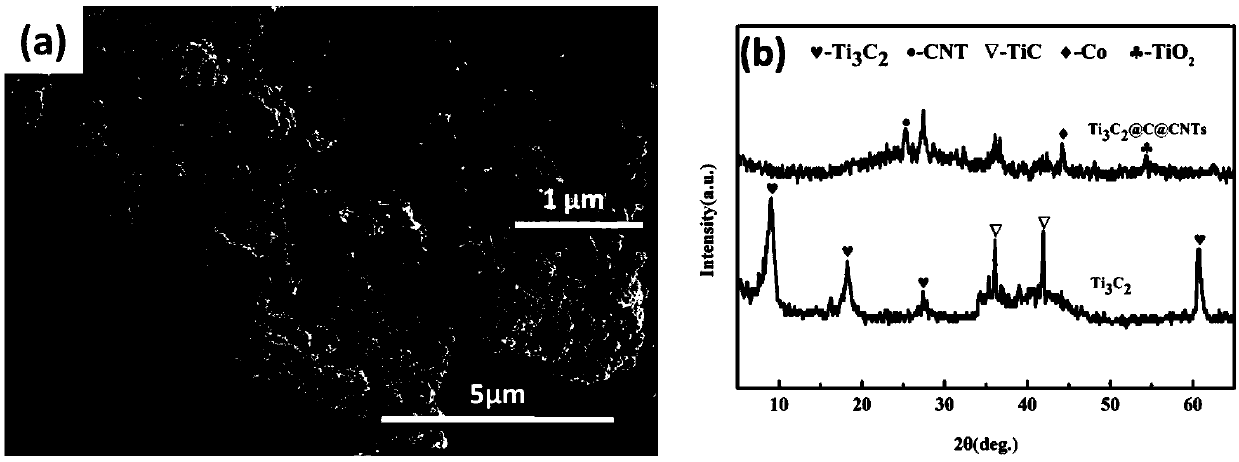

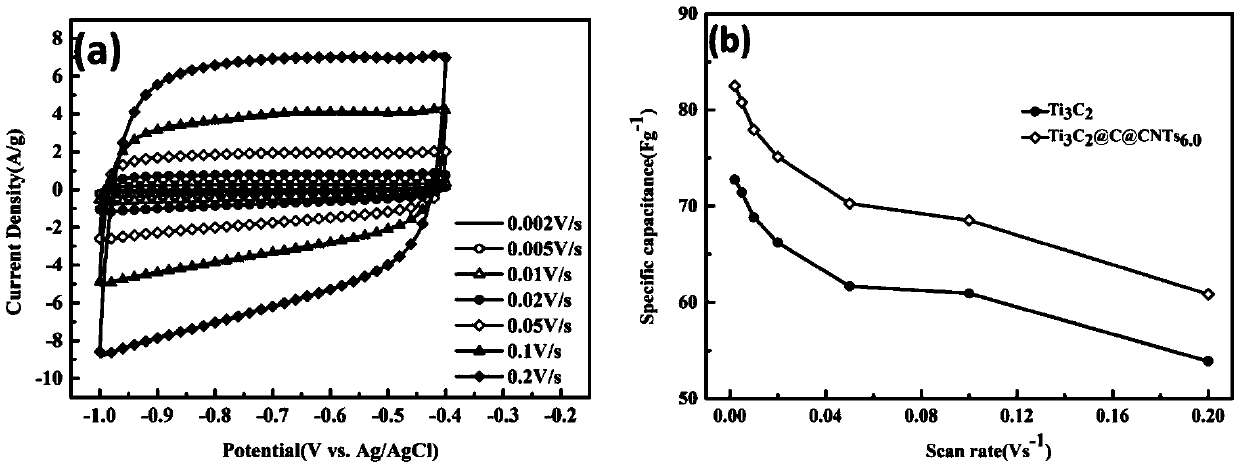

[0038] (1) Ti 3 C 2 Preparation of @C composite materials;

[0039] First, 100mg of Ti 3 C 2 Add the nano powder into 60mL ultrapure water, ultrasonically disperse for 30min; then, add 0.4g glucose, stir at room temperature for 30min; secondly, transfer it to a 100mL hydrothermal kettle, and react at 180℃ for 10h to obtain Ti 3 C 2 @C Composite.

[0040] (2) Ti 3 C 2 Preparation of @C@CNTs three-dimensional composite materials;

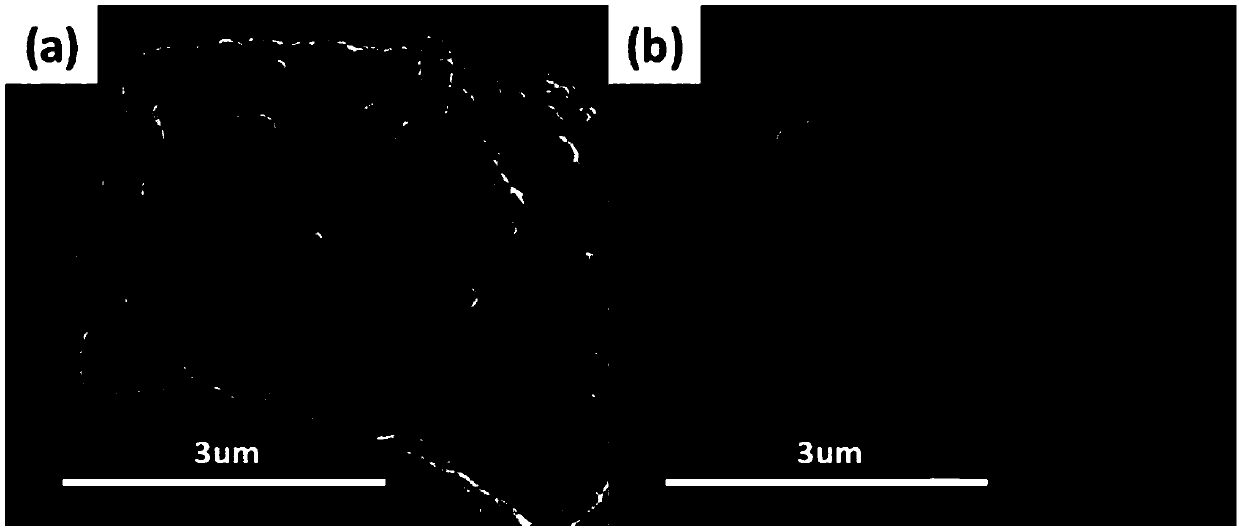

[0041] First, 300mg of Ti 3 C 2 @C Nanopowder, add into 200mL ultrapure water, ultrasonically disperse for 30min; then, add 0.29g Co(NO 3 ) 2 ·6H 2 O, stirred at room temperature for 4 hours; secondly, 6.0 g of urea was added, and the above mixed solution was continuously stirred at a constant temperature of 80 °C to evaporate water to obtain a gray precursor; finally, the precursor powder was ground with an agate mortar, and transferred to In an Ar atmosphere tube furnace, heat up to 900°C at a heating rate of 4°C / min, pyrolyze for 1 hou...

Embodiment 2

[0046] (1) Ti 3 C 2 Preparation of @C composite materials;

[0047] First, 100mg of Ti 3 C 2 Add the nano powder into 60mL ultrapure water, ultrasonically disperse for 30min; then, add 0.3g glucose, stir at room temperature for 30min; secondly, transfer it to a 100mL hydrothermal kettle, and react at 180℃ for 10h to obtain Ti 3 C 2 @C Composite.

[0048] (2) Ti 3 C 2 Preparation of @C@CNTs three-dimensional composite materials;

[0049] First, 300mg of Ti 3 C 2 @C Nanopowder, add into 200mL ultrapure water, ultrasonically disperse for 30min; then, add 0.29g Co(NO 3 ) 2 ·6H 2O, stirred at room temperature for 4 hours; secondly, 6.0 g of urea was added, and the above mixed solution was continuously stirred at a constant temperature of 80 °C to evaporate water to obtain a gray precursor; finally, the precursor powder was ground with an agate mortar, and transferred to In an Ar atmosphere tube furnace, heat up to 900°C at a heating rate of 4°C / min, pyrolyze for 1 hour...

Embodiment 3

[0051] (1) Ti 3 C 2 Preparation of @C composite materials;

[0052] First, 100mg of Ti 3 C 2 Add nano powder into 60mL ultra-pure water, ultrasonically disperse for 30min; then, add 0.2g glucose, stir at room temperature for 30min; secondly, transfer to 100mL hydrothermal kettle, react at 180℃ for 10h, you can get Ti 3 C 2 @C Composite.

[0053] (2) Ti 3 C 2 Preparation of @C@CNTs three-dimensional composite materials;

[0054] First, 300mg of Ti 3 C 2 @C Nanopowder, add into 200mL ultrapure water, ultrasonically disperse for 30min; then, add 0.29g Co(NO 3 ) 2 ·6H 2 O, stirred at room temperature for 4 hours; secondly, 6.0 g of urea was added, and the above mixed solution was continuously stirred at a constant temperature of 80 °C to evaporate water to obtain a gray precursor; finally, the precursor powder was ground with an agate mortar, and transferred to In an Ar atmosphere tube furnace, heat up to 900°C at a heating rate of 4°C / min, pyrolyze for 1 hour, cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com