Halloysite carbon dioxide adsorbent and preparation method thereof

A technology based on carbon dioxide and halloysite, applied in chemical instruments and methods, through adsorption, separation methods, etc., can solve the problems of temperature change sensitivity and poor selectivity of adsorbents, and achieve strong adsorption capacity, strong gas adsorption capacity, high The effect of adsorption performance and adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

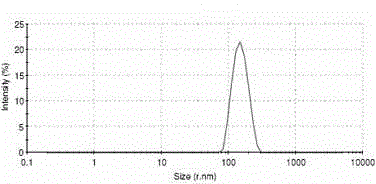

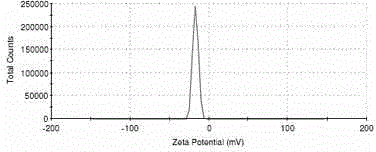

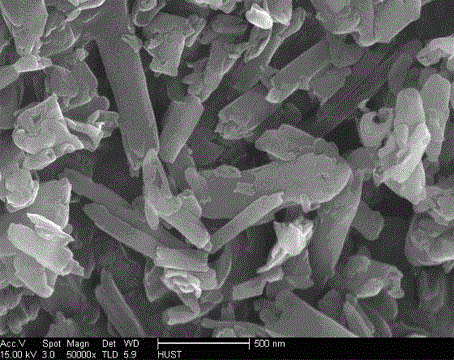

[0031] Add 10g of halloysite nanotubes and 300ml of methanol into a 500ml clean and dry three-necked bottle and mechanically stir to obtain a methanol dispersion of halloysite nanotubes, and then weigh 5g of polyethyleneimine (Mw=17000) and dissolve it in 60ml of methanol , obtain a methanol solution of polyethyleneimine, and then add it dropwise to the methanol dispersion of halloysite nanotubes while stirring, continue stirring for 3 hours, then stop stirring, and evaporate the methanol solvent by rotary evaporation at 50 ° C to obtain block Solid, finely ground, dried at 80°C and stored in vacuum to obtain halloysite-based carbon dioxide adsorbent. The specific particle size distribution diagram, SEM image and isoelectric point test diagram of the rockite nanotubes are shown in figure 1 , figure 2 and image 3 .

Embodiment 2

[0033]Add 10g of halloysite nanotubes and 300ml of ethanol into a 500ml clean and dry three-necked bottle and mechanically stir to obtain an ethanol dispersion of halloysite nanotubes, and then weigh 8g of polyacrylamide (Mw=1 million) and dissolve it in 20ml of methanol , to obtain an alcohol solution of polyacrylamide, and then add it to the methanol dispersion of halloysite nanotubes under ultrasonication, continue stirring for a period of time until the system is uniformly mixed, then stop stirring, and vacuum dry at 70°C to remove alcohol Solvent, to obtain blocky solid, grind it at 90°C, dry it and store it in vacuum to obtain halloysite-based carbon dioxide adsorbent.

Embodiment 3

[0035] Add 20g of halloysite nanotubes and 300ml of methanol into a 500ml clean and dry three-necked bottle and mechanically stir to obtain a methanol dispersion of halloysite nanotubes, and then weigh 5g of polyethyleneimine (Mw=900) and dissolve it in 60ml of ethanol , prepare the ethanol solution of polyethyleneimine, then add the ethanol solution of polyethyleneimine into the methanol solution of halloysite nanotubes while stirring, continue stirring for 3 hours, stop stirring, and evaporate the alcohol by rotary evaporation at 70 °C Solvent, to obtain blocky solid, grind it at 100°C, dry it and store it in vacuum to obtain halloysite-based carbon dioxide adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com