Special voice control bolt cutter for high-voltage live working robot

A working robot, high-voltage live technology, applied in computer control, general control systems, instruments, etc., can solve the problem that high-voltage live working robots cannot give full play to their advantages, restrict the application and promotion of live working robots, and cannot expand new fields, new applications, etc. problem, to achieve the effect of super anti-interference ability and reliability, increase operation safety and convenience, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

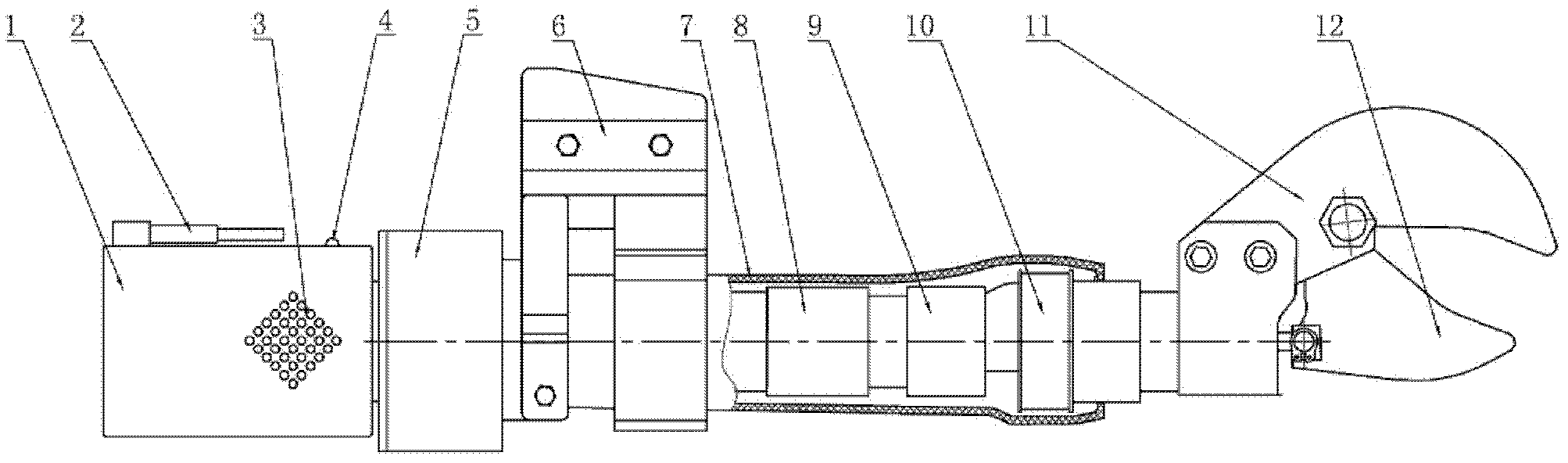

[0060] figure 1 Among them, the present invention consists of a bolt cutter main body, a sound-activated launching remote controller and a sound-activated assembly.

[0061] The voice control assembly housing 1 is fixed on the main housing 7 and includes an antenna 2 , a fan 3 and an indicator light 4 .

[0062] Wherein the bolt cutter main body is as figure 1 As shown, it includes a power supply 5, a manipulator engaging mechanism 6, a main housing 7, an electric motor 8, an oil pump 9, an oil cylinder 10, a fixed cutter 11, and a movable cutter 12.

[0063] The power supply 5 is assembled with the main casing 7 through a slot and a buckle. The manipulator engaging mechanism 6 is fixedly connected to the main casing 7, and is freely engaged and separated from the manipulator of the high-voltage live working robot. The motor 8 is assembled in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com