Method for separating and purifying puerarin monomers

A technology for separation and purification of puerarin, applied in the direction of organic chemistry, can solve the problems of low sample purity, cumbersome operation steps, and low sample recovery rate, and achieve the effect of high product purity, advanced technology and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix ethyl acetate, n-butanol and water in a volume ratio of 12:3:15, place in a separatory funnel, shake fully and let stand to separate layers, take the upper layer solution as the stationary phase and the lower layer solution as the mobile phase , for subsequent use; the puerarin crude product of 150mg (puerarin purity is 50%) is dissolved in 10mL lower floor solution, for subsequent use;

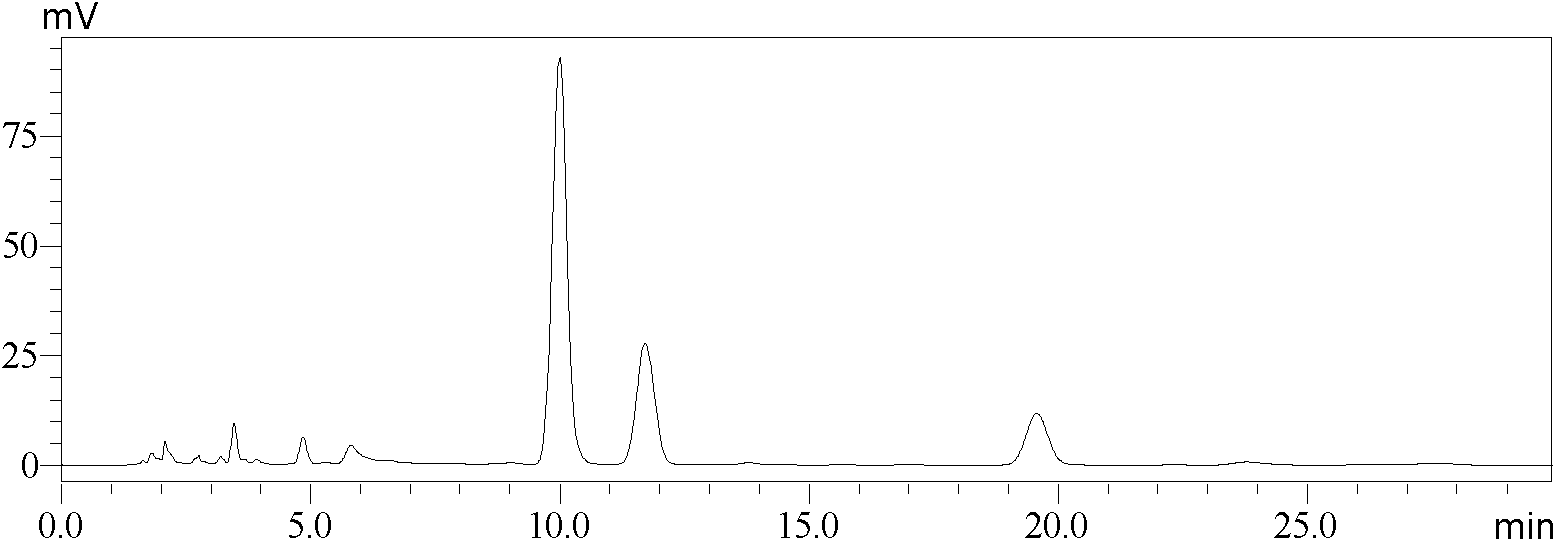

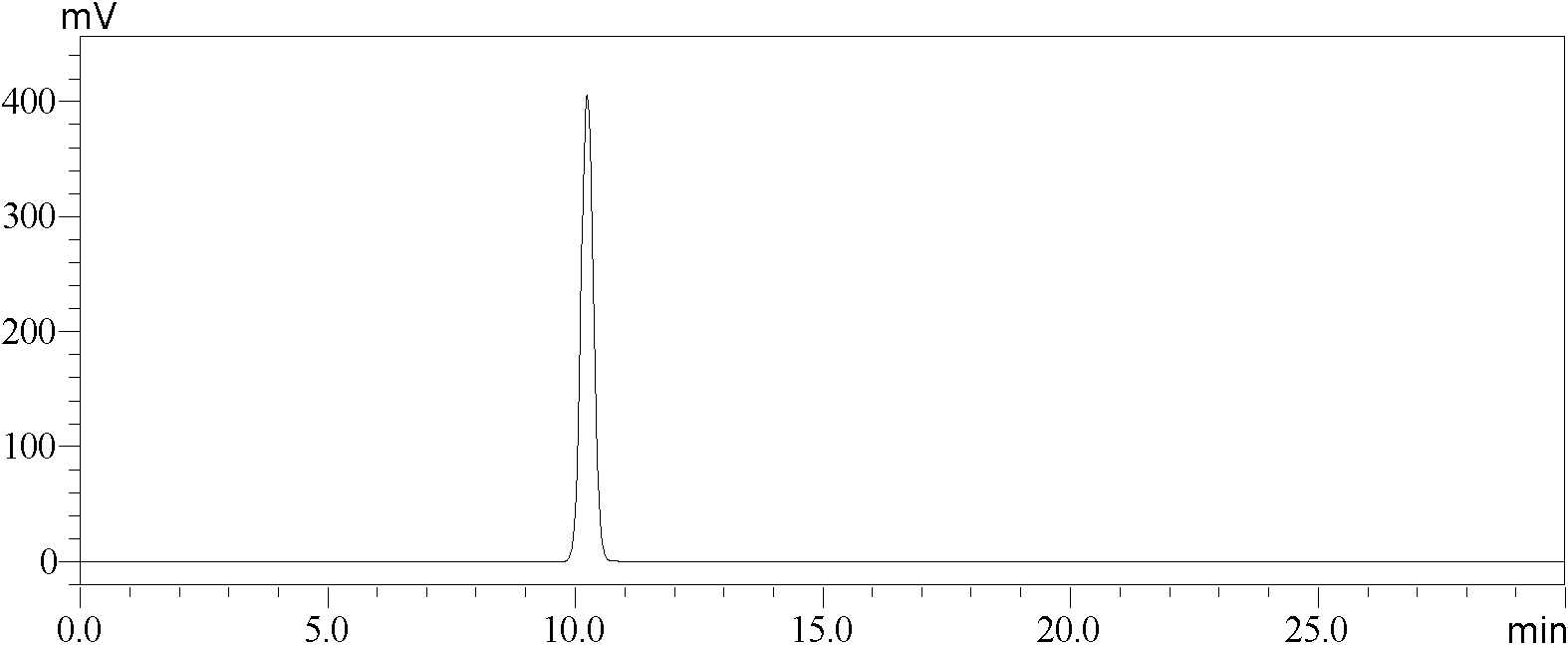

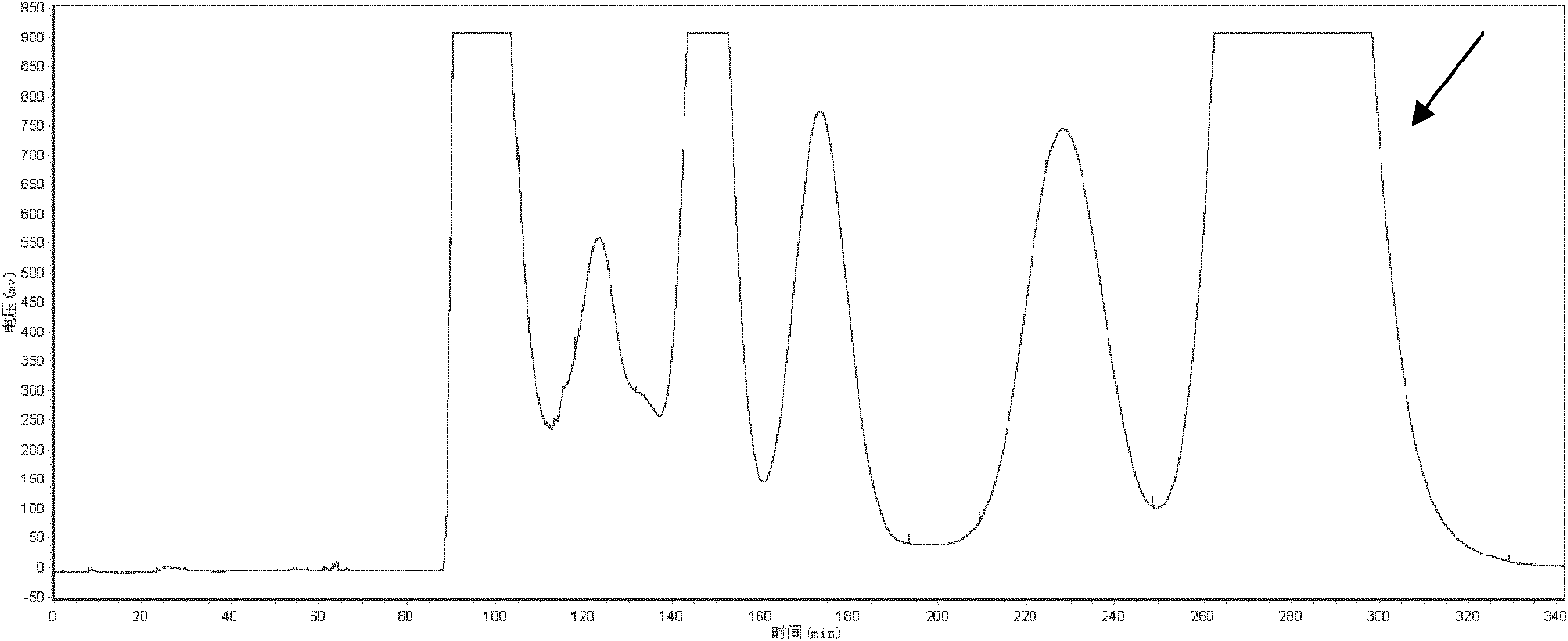

[0027] (2) Use semi-preparative high-speed countercurrent chromatograph, the ternary solvent system that above-mentioned ethyl acetate, n-butanol and water are formed is as separation solvent system; In the chromatographic column of high-speed countercurrent chromatograph, be full of stationary phase, then adjust rotating speed 850r / min to make the host rotate, set the temperature of the constant temperature water bath to 30°C, set the detection wavelength of the ultraviolet detector to 254nm, and then pump the mobile phase into the chromatographic column at 1.5mL / min; Enter p...

Embodiment 2

[0033] (1) Mix ethyl acetate, n-butanol and water in a volume ratio of 5:3:8, place in a separatory funnel, shake fully and let stand to separate layers, take the upper layer solution as the stationary phase and the lower layer solution as the mobile phase , for subsequent use; 200mg puerarin crude product (the purity of puerarin is 65%) was dissolved in 15mL lower layer solution, for subsequent use;

[0034] (2) Use semi-preparative high-speed countercurrent chromatograph, with the ternary solvent system that above-mentioned ethyl acetate, n-butanol and water form as separation solvent system; In the chromatographic column of high-speed countercurrent chromatograph, be full of stationary phase, then adjust rotating speed 950r / min to make the host rotate, set the temperature of the constant temperature water bath to 25°C, set the detection wavelength of the ultraviolet detector to 254nm, and then pump the mobile phase into the chromatographic column at 2mL / min; Crude product ...

Embodiment 3

[0036] (1) Mix ethyl acetate, n-butanol and water in a volume ratio of 7:3:10, place in a separatory funnel, shake fully and let stand to separate layers, take the upper layer solution as the stationary phase and the lower layer solution as the mobile phase , for subsequent use; 250mg puerarin crude product (the purity of puerarin is 80%) is dissolved in 20mL lower layer solution, for subsequent use;

[0037] (2) Use semi-preparative high-speed countercurrent chromatograph, with the ternary solvent system that above-mentioned ethyl acetate, n-butanol and water are formed as separation solvent system; In the chromatographic column of high-speed countercurrent chromatograph, be full of stationary phase, then adjust rotating speed 800r / min to make the host rotate, set the temperature of the constant temperature water bath to 20°C, set the detection wavelength of the ultraviolet detector to 254nm, and then pump the mobile phase into the chromatographic column at 1.5mL / min; Enter pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com