Method for preparing rosin modified organic silicon resin

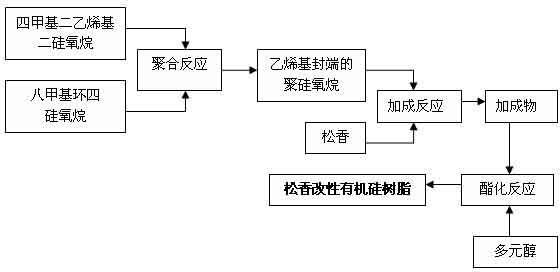

A technology of rosin modification and organosilicon, which is applied in the field of preparation of rosin-modified silicone resin, can solve problems such as no public reports on the preparation method of rosin-modified silicone resin, and achieves the promotion of industrial development and the improvement of adhesion. , the effect of improving heat resistance and electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

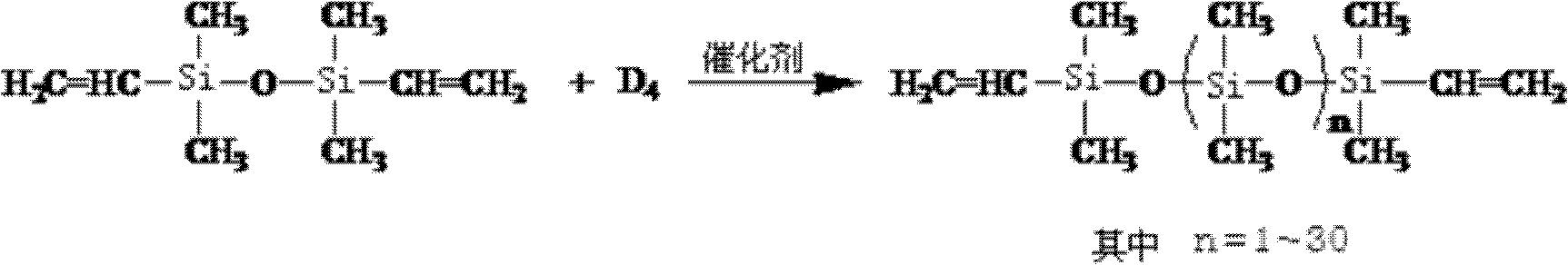

[0036] (1) Take 10.0g of tetramethyldivinyldisiloxane and 50g of octamethylcyclotetrasiloxane (D4) and place it in a 500ml three-necked flask, start the stirrer, add 3.0g of concentrated sulfuric acid as a catalyst, heat The temperature is raised to 60°C, the reaction is kept under normal pressure and stirred for 6 hours, then lowered to below 50°C to remove the filter agent, and the low molecular weight is removed at 120-160°C for 5-8 hours at a pressure below 133Kpa to obtain an intermediate vinyl-terminated polymer. Siloxane, low molecular weight can be reused.

[0037] (2) after the above-mentioned (1) reaction is finished, add 40g rosin and 0.08g hydroquinone catalyst, be warming up to 200 DEG C and carry out Diels-Alder addition reaction, after 6 hours of reaction, vacuumize to 3mmHg, remove low boiling point Impurities, the product was cooled to room temperature to obtain an adduct of vinyl terminated polysiloxane and rosin.

[0038] (3) then add pentaerythritol 6.4g, ...

Embodiment 2

[0040] (1) Take 10.0g of tetramethyldivinyldisiloxane and 50g of octamethylcyclotetrasiloxane (D4) and place it in a 500ml three-necked flask, start the stirrer, and add 4.0g of strongly acidic styrene resin as a The catalyst is heated to 60°C, reacted under normal pressure and kept stirring for 6 hours, then lowered to below 50°C to remove the filter agent, and the low molecular weight is removed at 120-160°C for 5-8 hours at a pressure below 133Kpa to obtain the intermediate vinyl End-capped polysiloxane, low molecular weight can be reused.

[0041] (2) after the above-mentioned (1) reaction is finished, add 60g rosin and 0.10g p-toluenesulfonic acid catalyst, be warming up to 200 DEG C and carry out Diels-Alder addition reaction, after 6 hours of reaction, vacuumize to 3mmHg, remove Low boiling point impurities, the product was cooled to room temperature to obtain the adduct of vinyl terminated polysiloxane and rosin.

[0042] (3) then add pentaerythritol 15.6g, glycerol 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com