Preparation method of anode material of Li-Se battery and lithium battery

A cathode material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low electric capacity, poor electrical stability, and unsatisfactory cyclability of cathode materials, and achieve high practical value, electric power. Good chemical stability, increasing the effect of intercalation and decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

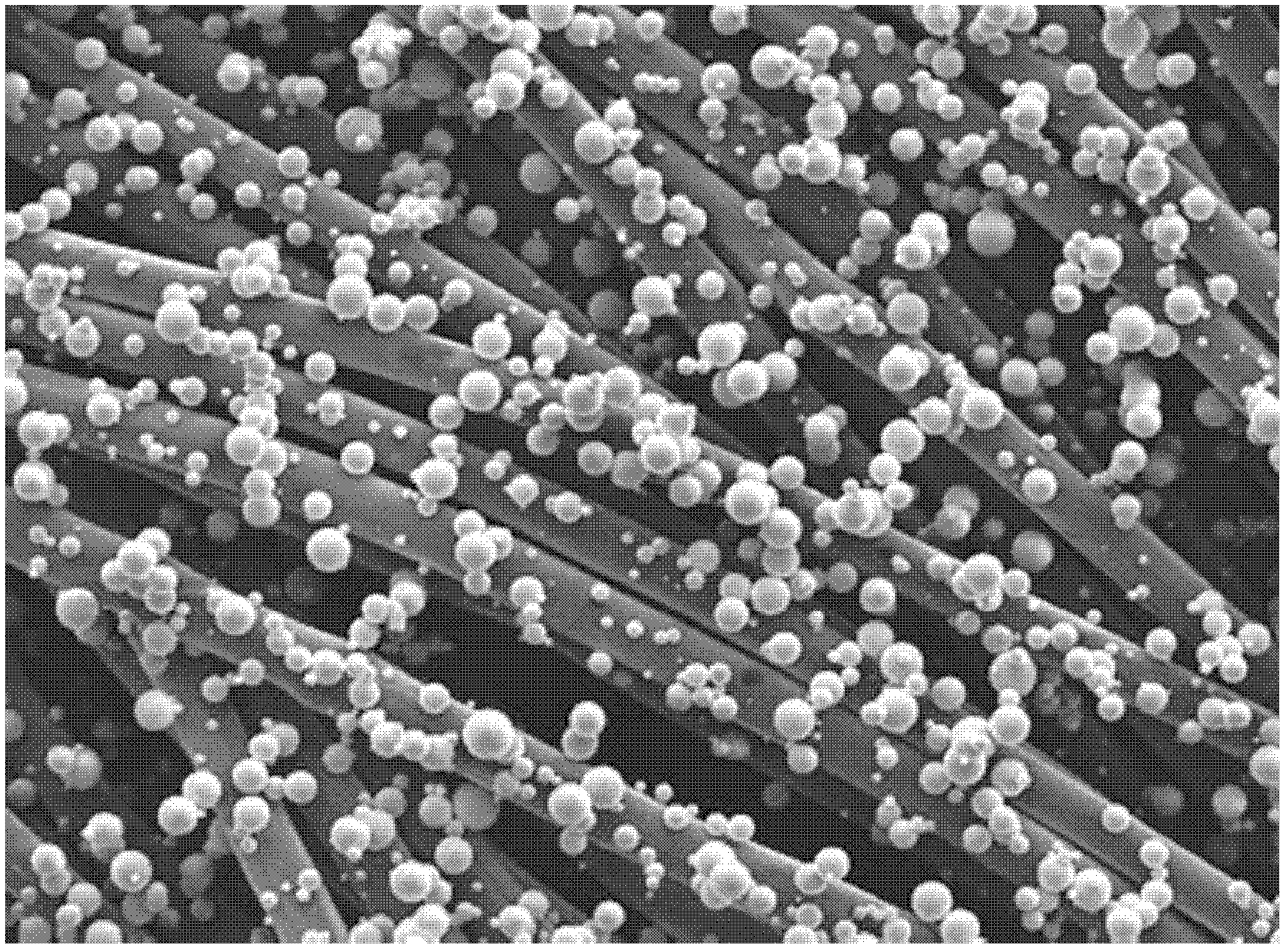

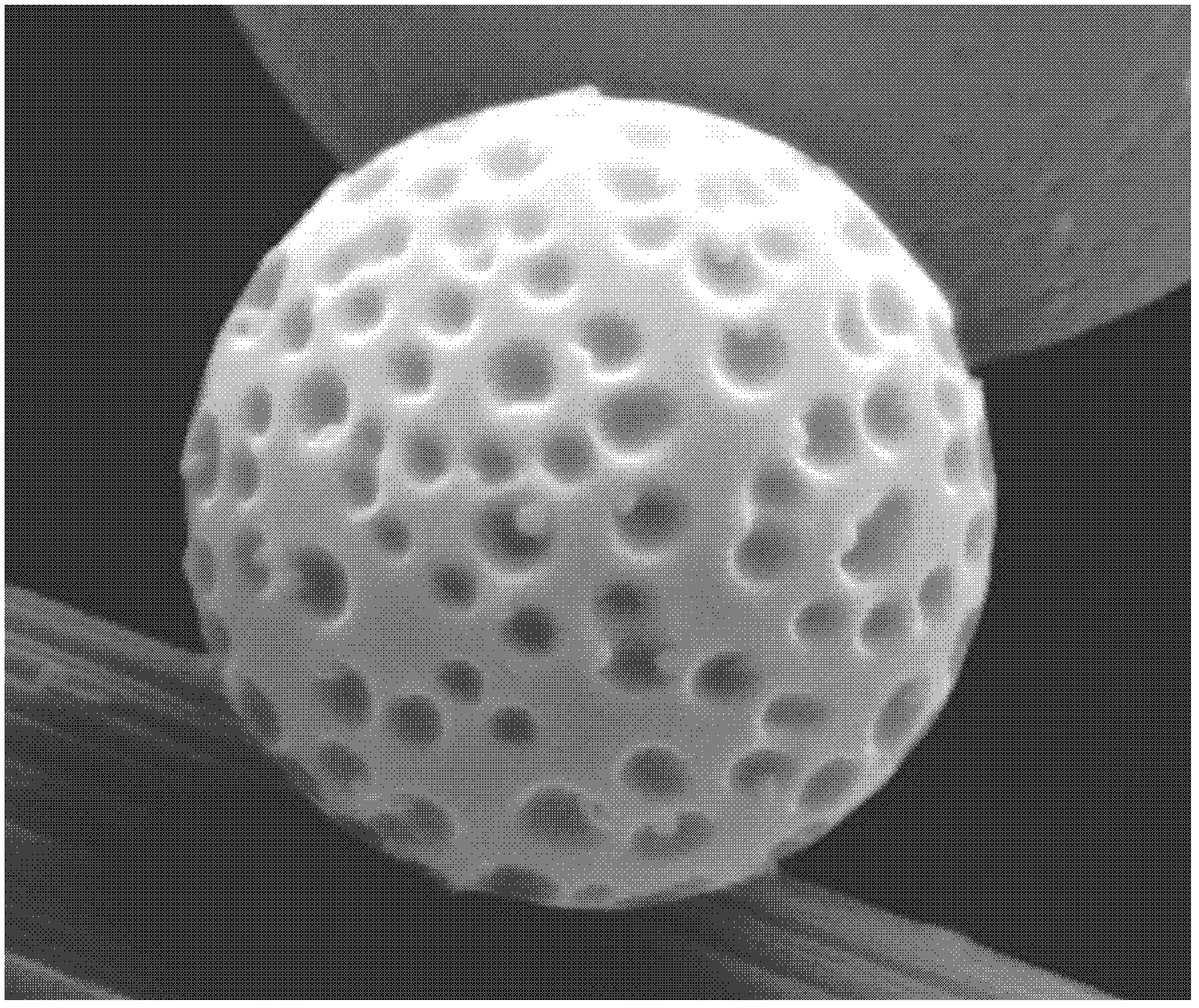

[0023] Embodiment 1: Porous elemental selenium microspheres

[0024] 1. Preparation of cathode materials for lithium batteries. Microspheres of elemental selenium were synthesized on carbon cloth by gas phase method, such as figure 2 As shown, compared with the pure carbon cloth, there is an obvious layer of microspheres grown on the carbon cloth.

[0025] The preparation steps are as follows:

[0026] (1) take selenium powder and put into porcelain boat, porcelain boat is put into the quartz tube in the horizontal tube furnace;

[0027] (2) Clean and dry the substrate carbon cloth or aluminum foil, and place the substrate in the downstream low temperature area of the quartz tube;

[0028] (3) feed nitrogen for 20 minutes, and exhaust the air in the quartz tube;

[0029] (4) Adjust the nitrogen flow rate to 100 sccm, heat the tube furnace to 400°C-800°C, and keep it warm for 30min-60min.

[0030] (5) After the heat preservation of the tube furnace is completed and the ...

Embodiment 2

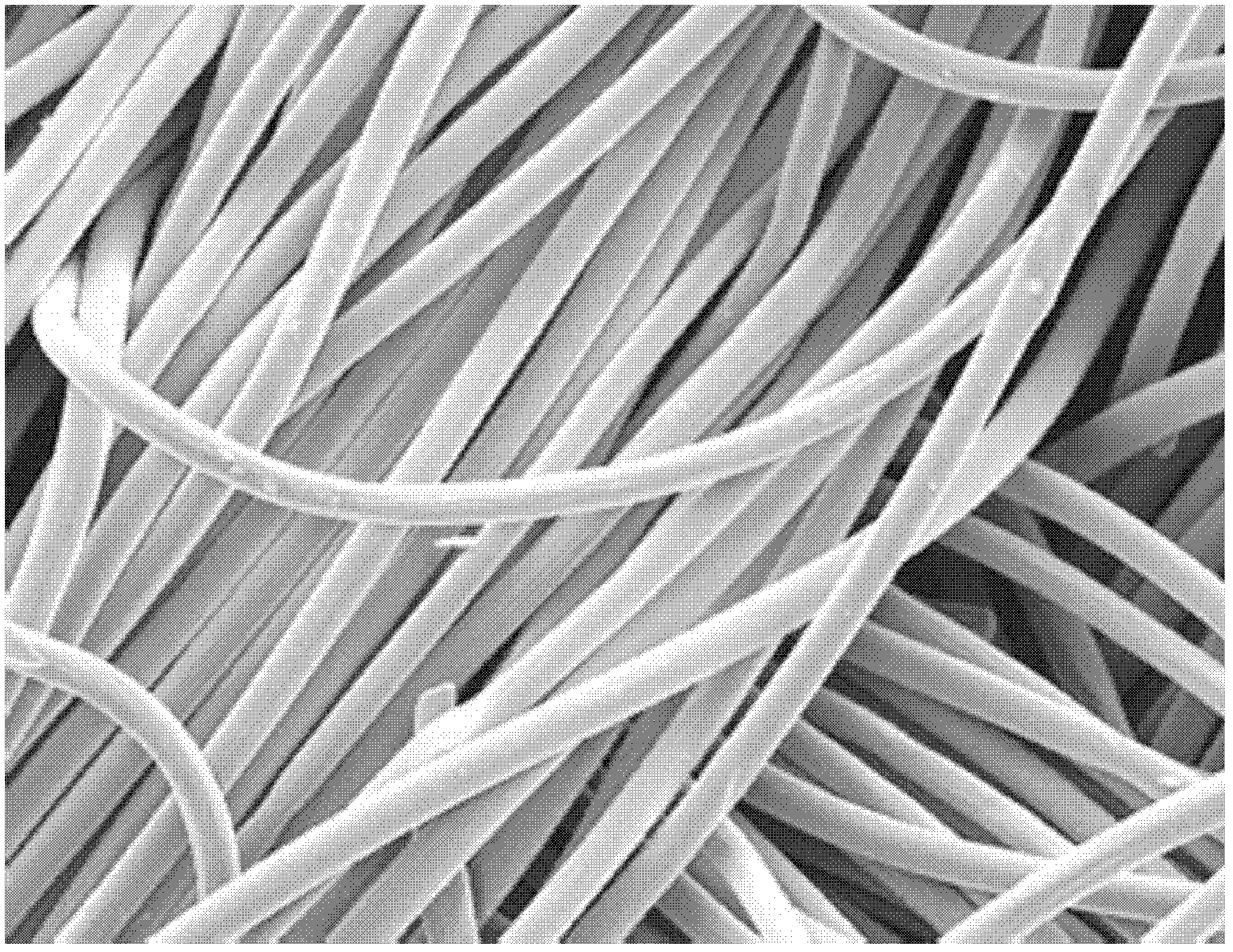

[0035] Embodiment 2 Selenium nanowires

[0036] (1) take selenium powder and put into porcelain boat, porcelain boat is put into the quartz tube in the horizontal tube furnace;

[0037] (2) Clean and dry the substrate copper foil, vapor-deposit a layer of gold on the substrate, and place the substrate in the downstream low temperature zone of the quartz tube;

[0038] (3) Pass in argon gas for 20 minutes, and exhaust the air in the quartz tube;

[0039] (4) Adjust the nitrogen flow rate to 20 sccm, heat the tube furnace to 250°C-400°C, and keep it warm for 30min-60min.

[0040] (5) After the heat preservation of the tube furnace is completed and the temperature drops to room temperature, take out the substrate.

Embodiment 3

[0041] Embodiment 3 Selenium nanobelts

[0042] (1) take selenium powder and put into porcelain boat, porcelain boat is put into the quartz tube in the horizontal tube furnace;

[0043] (2) cleaning and drying the nickel foam on the substrate, vapor-depositing a layer of gold on the substrate, and placing the substrate in the downstream low temperature zone of the quartz tube;

[0044] (3) feed nitrogen for 20 minutes, and exhaust the air in the quartz tube;

[0045] (4) Adjust the nitrogen flow rate to 20 sccm, heat the tube furnace to 400°C-600°C, and keep it warm for 30min-60min.

[0046] (5) After the heat preservation of the tube furnace is completed and the temperature drops to room temperature, take out the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com