Recycling comprehensive utilization technology for pulping black liquor or red liquor

A technology for pulping black liquor and red liquor, which is applied in the field of paper pulping, can solve the problems of waste of water and sludge resources, backward treatment technology and high treatment costs, and achieve low treatment costs, less investment in equipment, and elimination of pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

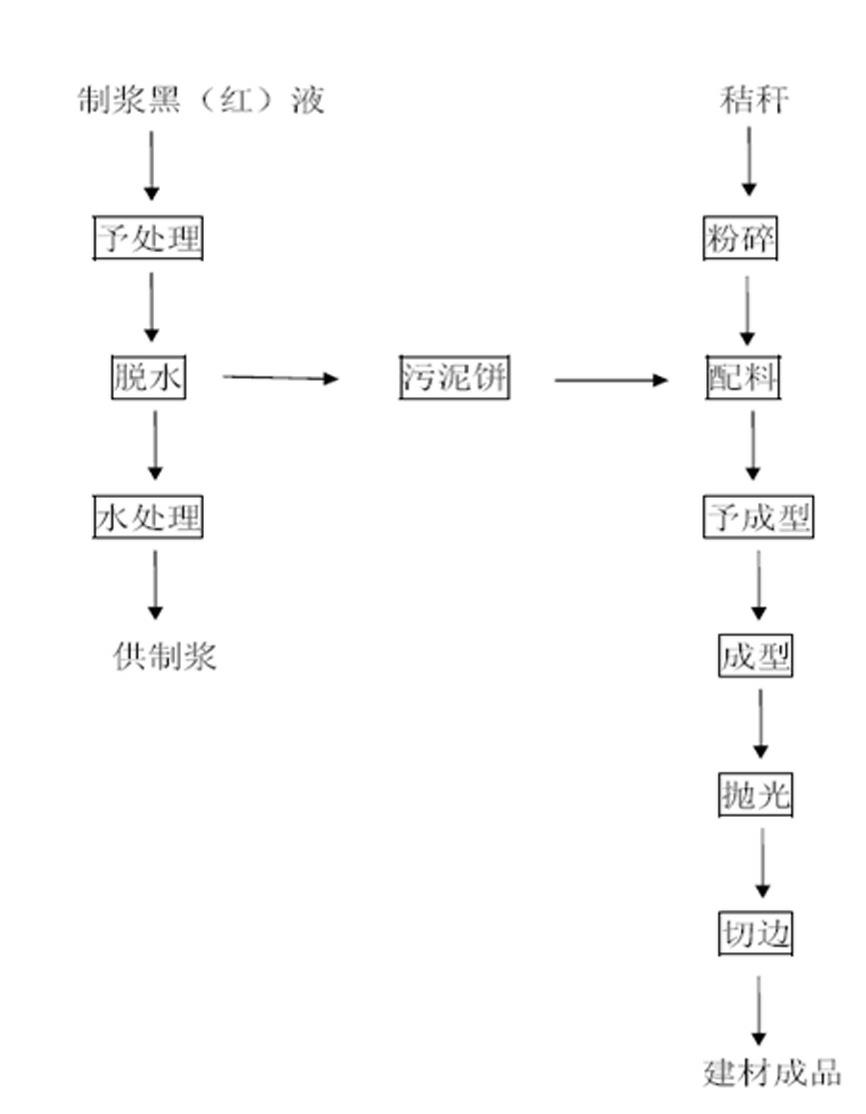

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the processing of black liquor

[0055] Taking the alkaline pulping of Northeast Korean pine in Yueyang Paper Mill as an example, the black liquor is comprehensively utilized and treated through the following process.

[0056] Pretreatment: Add CPAM grafted starch to the black liquor pool (with a low-speed agitator), the dosage is 2.5% of the black liquor, stir at a low speed for 10 minutes, then add H 2 SO 5 , the dosage is 3% of the amount of black liquor, stirred at a low speed for 10 minutes to flocculate the solids in the black liquor to obtain a pretreatment liquor.

[0057] Dehydration: Send the pretreatment liquid into the filter press dehydrator ZQWY-50, so that the flocculated solids in the pretreatment liquid are press-filtered into sludge cakes, and the detached water is sent to the water treatment tank.

[0058] Water treatment: In the water treatment tank, add CaCO 3 Adjust the pH to 7, then add the chelating agent DTPMPA, the dosage is...

Embodiment 2

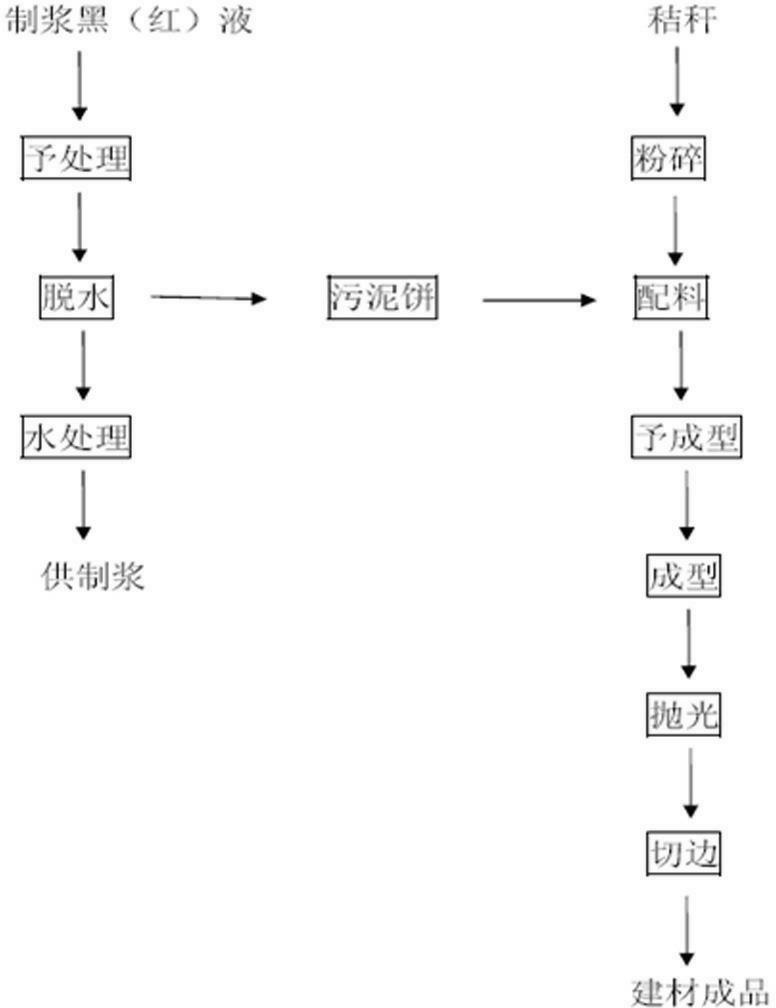

[0066] Embodiment 2: the processing of red liquor

[0067] Taking the sulfite pulping of Yueyang Hongyun Paper Technology Research Institute Co., Ltd. as an example, the red liquor is comprehensively utilized and treated through the following process.

[0068] Pretreatment: Add CPAM grafted starch to the red liquor pool (with a low-speed agitator), the dosage is 3% of the black liquor, stir at a low speed for 10 minutes, then add 2CaCO 3 ·3H 2 o 2 , the dosage is 3.5% of the amount of black liquor, stirred at a low speed for 10 minutes to flocculate the solids in the black liquor to obtain a pretreatment liquor.

[0069] Dehydration: Send the pretreatment liquid into the filter press dehydrator ZQWY-50, so that the flocculated solids in the pretreatment liquid are press-filtered into sludge cakes, and the detached water is sent to the water treatment tank.

[0070] Water treatment: In the water treatment tank, add sulfuric acid to adjust the pH to 7, then add the chelati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com