Sectional type ammonia generating device for discomposing solid urea

A solid urea, segmented technology, applied in the direction of silencer, exhaust device, separation method, etc., can solve the problems of nitrate deposition, easy freezing, energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

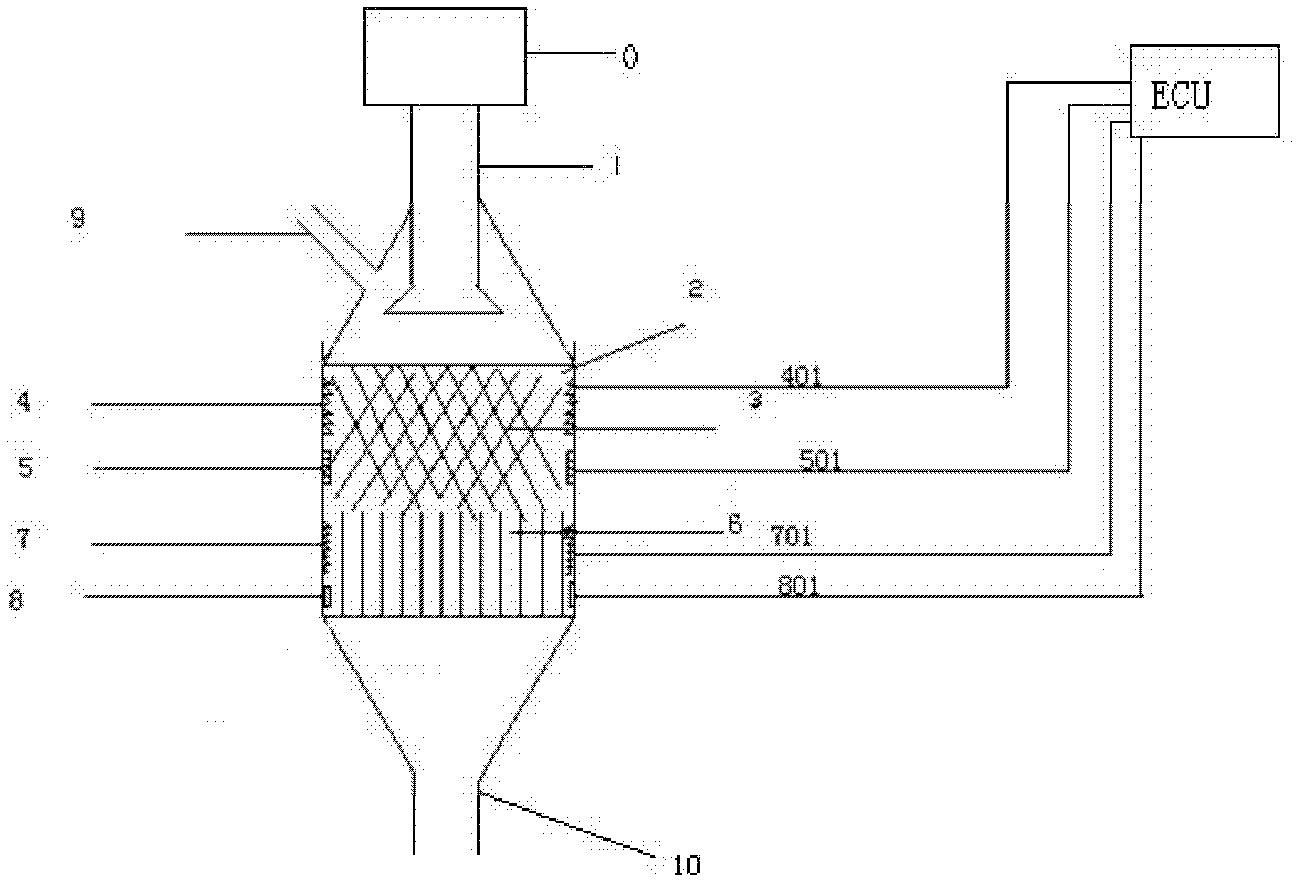

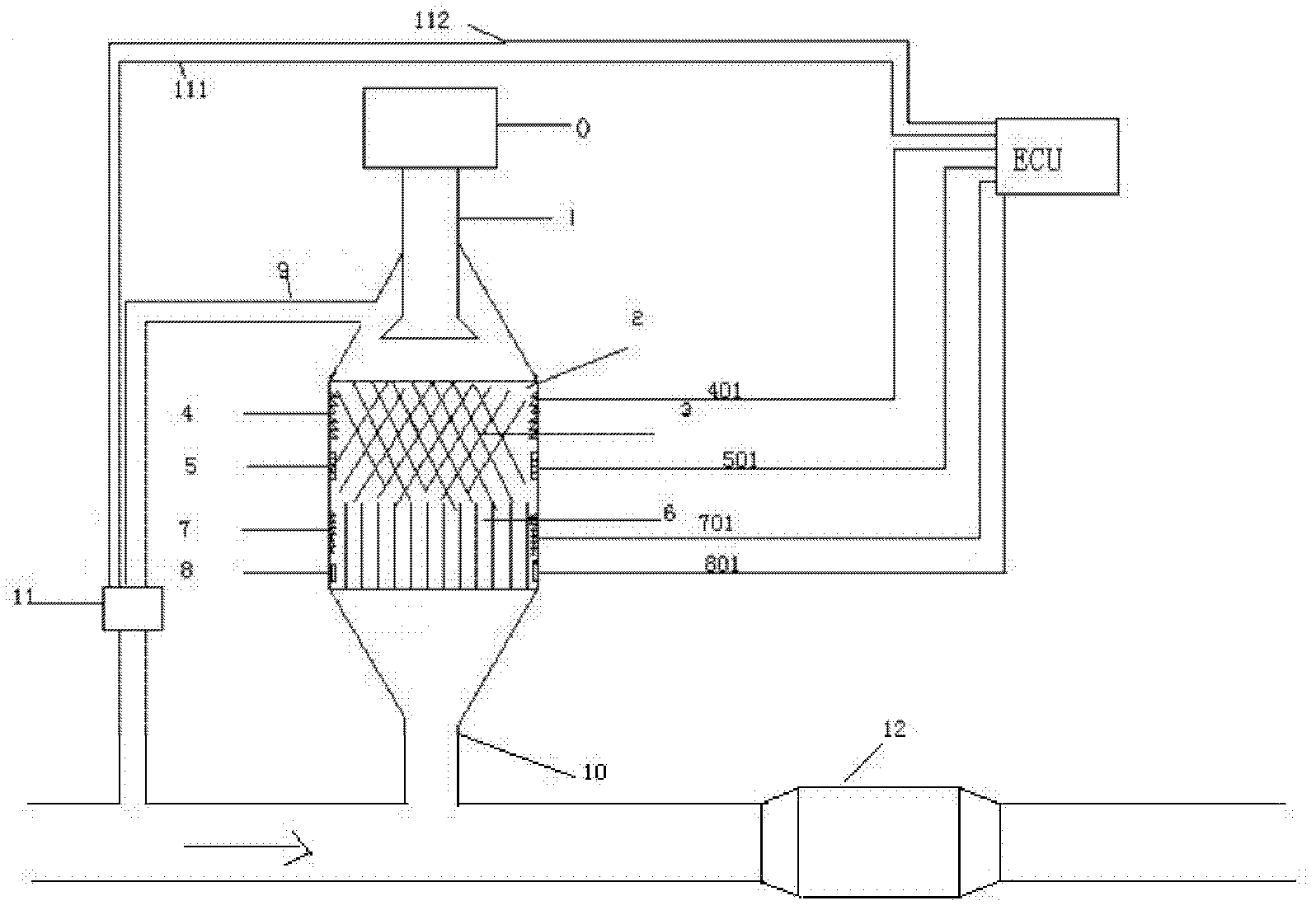

[0048] figure 2 This shows a specific embodiment of the device of the present invention. In this solution, the ammonia production device from urea decomposition of the present invention is installed in front of the exhaust gas treatment device in the exhaust gas discharge pipeline.

[0049] In this solution, when the exhaust gas of the car starts to be discharged, the ECU starts the heating program of the electric heating device through the command conduction lines 401 and 701, so that the electric heating devices 4 and 7 start heating. The device 11 in the figure represents a water vapor flow meter, which can control the gas flow entering the ammonia reaction tank 2 through the water vapor conveying pipe 9. The flow rate of water vapor passing through the water vapor flow meter 11 is controlled by the ECU. The water vapor flow meter 11 Transmit the sensed water vapor flow value to the ECU through the command transmission wire 111, and then the ECU transmits the feedback signal ...

Embodiment 2

[0051] 4.94g(Al(NO 3 ) 3 9H 2 O is dissolved in 20g of distilled water to form solution A;

[0052] Mix 5.712g of anhydrous ethanol solution, 3ml of distilled water, and 0.2ml of 65% nitric acid with a mass concentration of nitric acid, and then weigh 6.7695g of ethyl orthosilicate solution, slowly adding 4ml of ethyl orthosilicate every 1 minute Pour into the mixed solution of this step and stir vigorously at a speed of, and finally form a transparent and clear solution B;

[0053] Pour liquid B into solution A at a speed of 2ml / min, stir vigorously for 0.5 hours and age for 12 hours to finally form a glass coating sol solution.

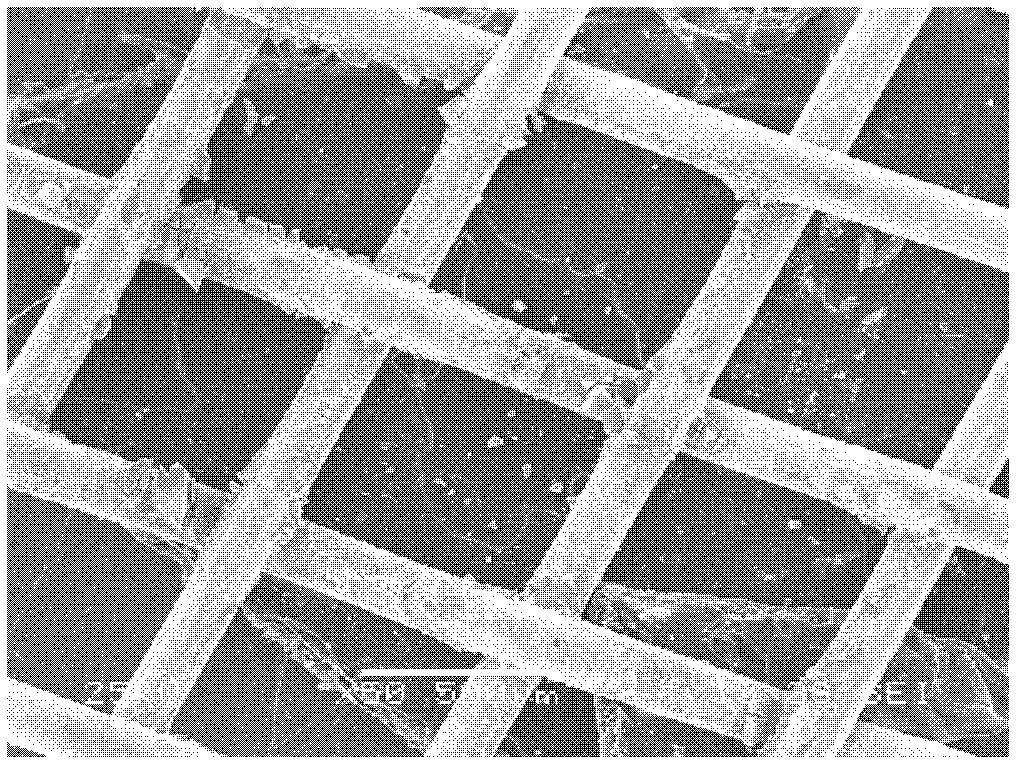

[0054] Take 5 pieces of nickel-chromium-iron metal wire mesh, each piece of metal wire mesh is a square with a side length of 5 cm, and the metal wire mesh has an aperture of 300 meshes. Perform the pretreatment described in the content of the invention, and then immerse the metal wire mesh carrier into the previous preparation Soak in the coating sol sol...

Embodiment 3

[0060] Add 14g Al(NO 3 ) 3 9H 2 O is dissolved in 40g of distilled water to form solution A;

[0061] Mix 5.712g of anhydrous ethanol solution, 3ml of distilled water, and 0.2ml of 65% nitric acid with a mass concentration of nitric acid, then weigh 6.6g of ethyl orthosilicate solution, slowly reduce the amount of ethyl orthosilicate to 4ml every 1 minute Pour into the mixed solution of this step and stir vigorously at a speed of, and finally form a transparent and clear solution B;

[0062] Pour liquid B into solution A at a speed of 2ml / min, continuously and vigorously stir for 0.5 hours, aging for 12 hours, and finally form a ratio of catalyst sol solution.

[0063] Take 5 nickel-chromium-iron metal honeycomb supports, each metal support is a cylinder with a diameter of 5cm and a height of 7cm. The metal supports are subjected to the pretreatment described above, and then the metal honeycomb supports are immersed in the above catalyst solution, each time 10 minutes, each coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com