Method for analyzing ferrous iron in iron ore based on X fluorescence spectrum

An analysis method, a technique of fluorescence spectroscopy, applied in the field of analysis of II-valent iron in iron ore, can solve problems such as unrecognizable signals, achieve the effects of fast speed, good precision of the method, and avoid cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] A method for analyzing ferrous iron in iron ore based on X-ray fluorescence spectrum, comprising the following steps:

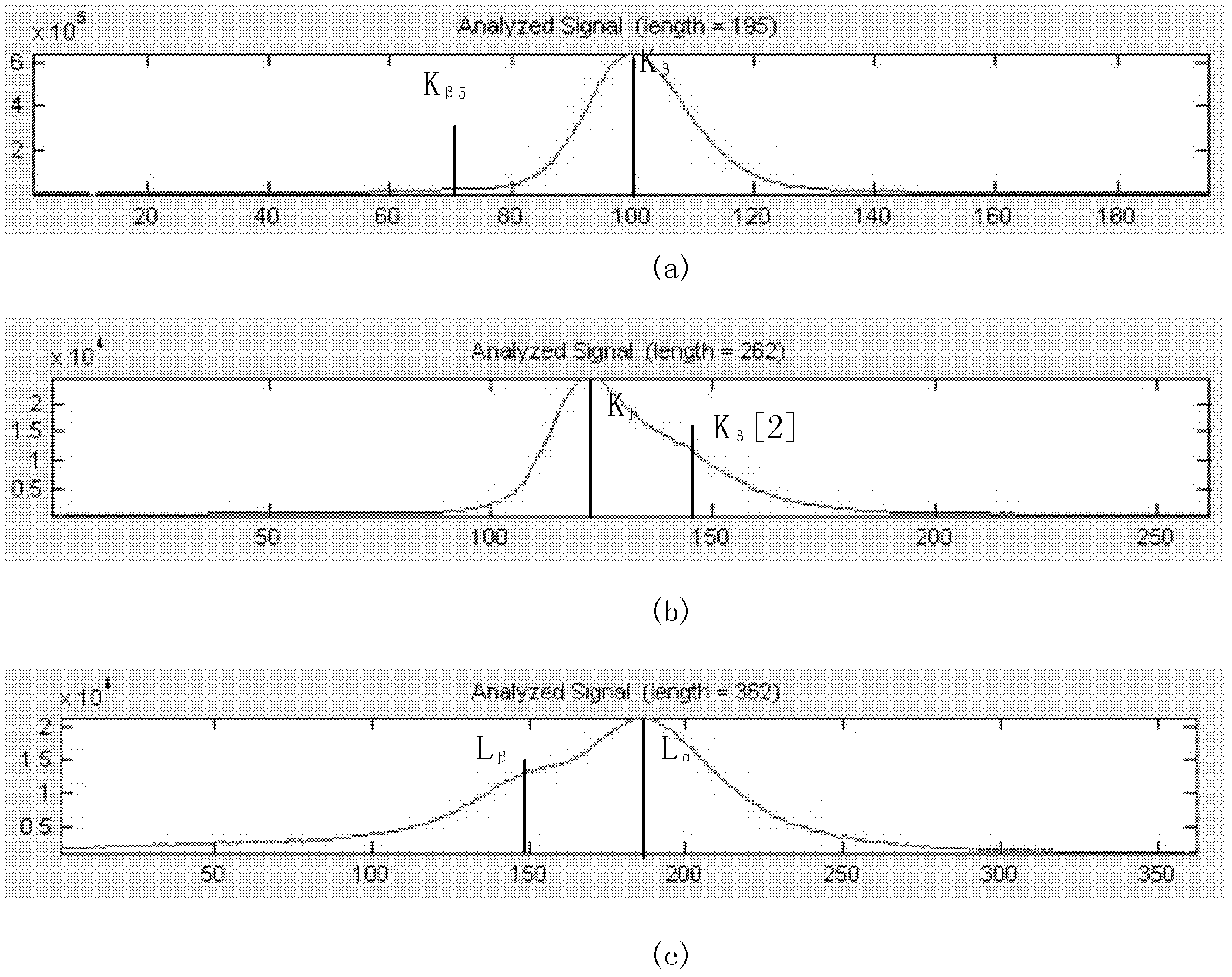

[0016] 1) Prepare a total amount of 0.5 g of FeO and Fe 2 o 3 Mixture series of mixed standard samples, in which the mass fraction of FeO is 0%, 24.85%, 51.68%, 74.85%, 100%, FeO and Fe 2 o 3 After mixing, it is ground in a vibrating grinder so as to be fully mixed. With 15 grams of borax as a substrate, it is pressed into a disc with a diameter of 38 mm and a thickness of about 10 mm in a hydraulic press as a sample. Test reagent FeO, Fe 2 o 3 All use high-purity grade. The instrument is German Bruker AXS-S8, tube voltage 30kV, tube current 116mA, end window rhodium target, spectroscopic crystal LiF200 and XS-55, collimator 0.17°, detector FC, scan step 0.018°, counting time 2.5~ 4.5s. K for iron β 、K β 2nd ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com