Medical type all-solid potassium ion selectivity sensor and preparation method thereof

A potassium ion, selective technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of not easy to carry, high cost, cumbersome detection process, etc., to simplify the structure and production process, achieve integration and miniaturization , The effect of accurate and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

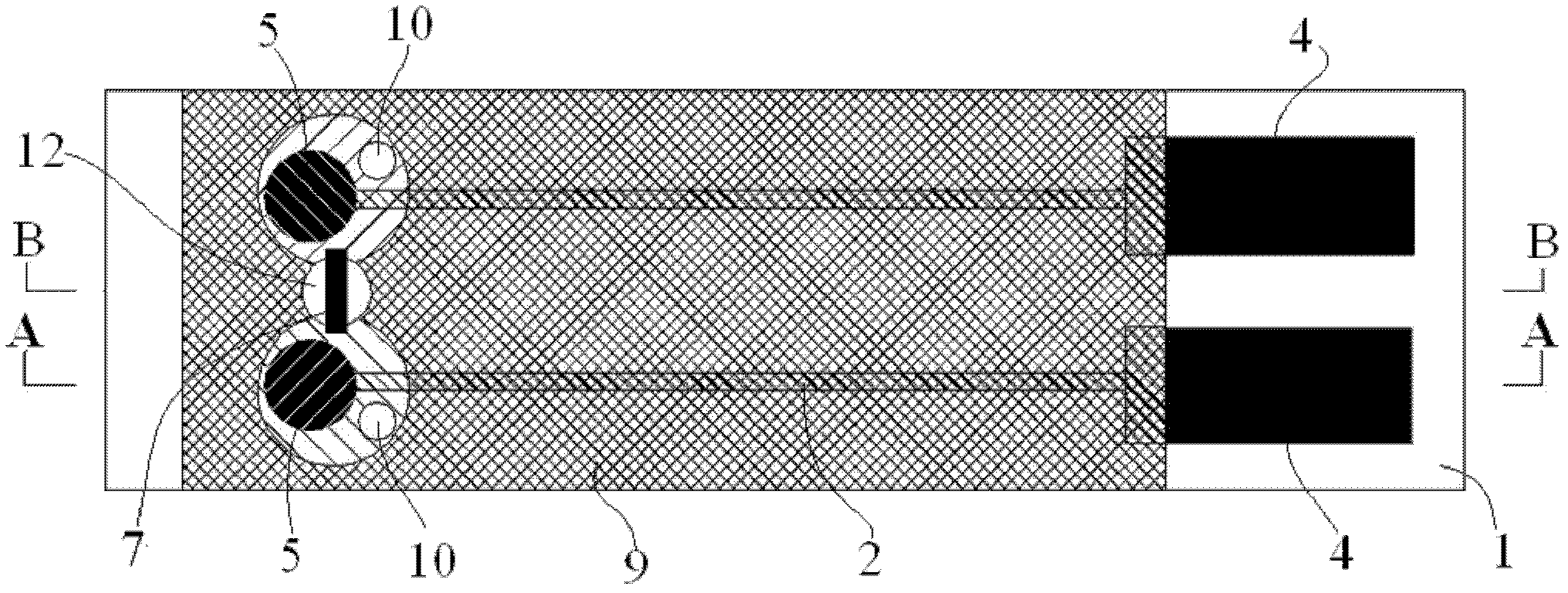

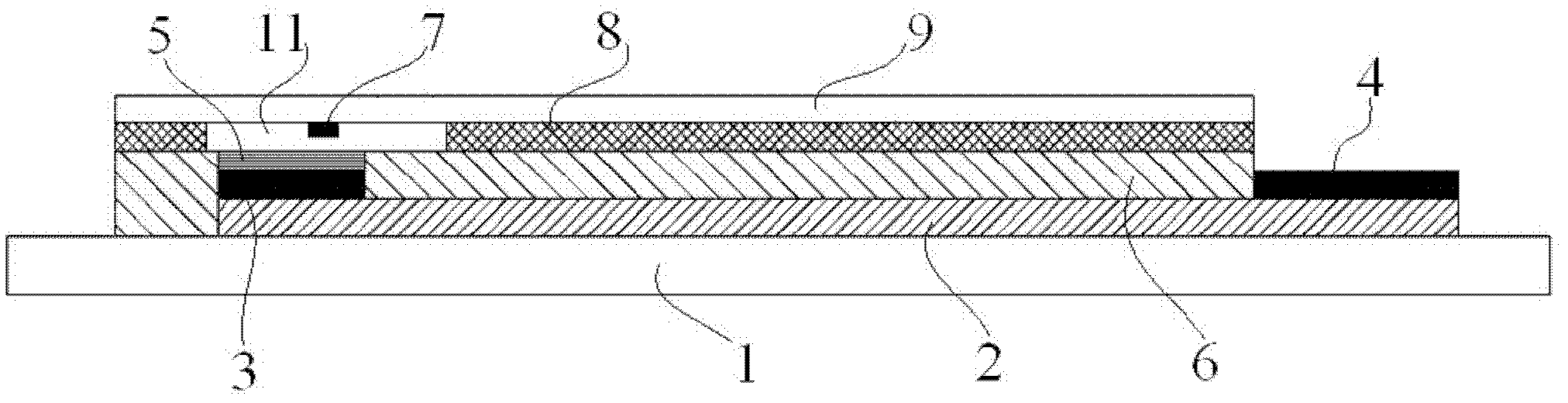

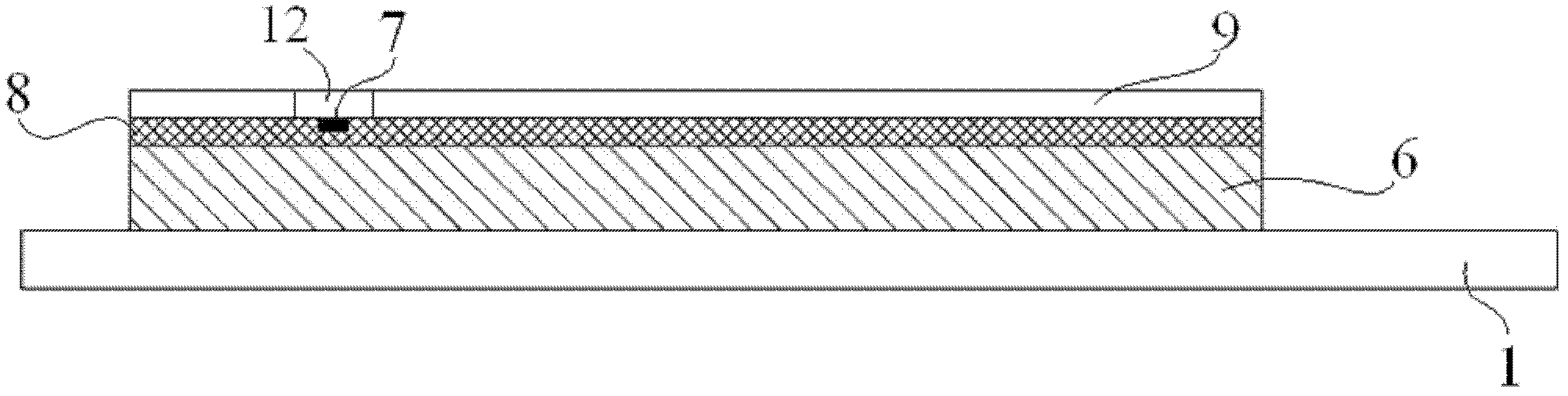

[0043] Such as figure 1 ,Such as figure 2 and image 3 As shown, a medical all-solid-state potassium ion selective sensor includes a substrate 1, two potassium ion selective working electrodes arranged side by side with the same structure, an insulating layer 6 and a salt bridge 7;

[0044] The potassium ion selective working electrode comprises a conductive layer 2, a reaction electrode 3, a contact electrode 4 and a potassium ion sensitive membrane 5, and the conductive layers 2 of the two potassium ion selective working electrodes are covered side by side on the described substrate 1, and the two The reaction electrodes 3 of the potassium ion selective working electrodes are arranged side by side at one end of the respective conductive layers 2, and the contact electrodes 4 of the two potassium ion selective working electrodes are arranged side by side at the other end of the respective conductive layers 2, and each reaction electrode 3 is arranged side by side. Covered ...

Embodiment 2

[0049] (1) On the organic polymer material substrate, the conductive material is arranged in turn to form the conductive layer, the reaction electrode and the contact electrode of the two potassium ion selective working electrodes; the conductive silver paste is printed on the polyethylene substrate by screen printing technology to form side by side The conductive layer of each potassium ion selective working electrode, and then print conductive carbon paste at one end of each conductive layer to form two side-by-side reaction electrodes, and print conductive carbon paste at the other end of each conductive layer to form two side-by-side contact electrodes.

[0050] (2) Pretreat the surface of the reaction electrode with absolute ethanol to remove the floating dust on the surface, so that the surface is clean and the state is consistent;

[0051] (3) Weigh 3mg of valinomycin and 1mg of tetrakis(4-chlorophenyl)potassium borate in 1.5mL of 3% PVC in tetrahydrofuran (3g of PVC is ...

Embodiment 3

[0062] (1) On the organic polymer material substrate, the conductive material is arranged in turn to form the conductive layer, the reaction electrode and the contact electrode of the two potassium ion selective working electrodes; the conductive silver paste is printed on the polyethylene substrate by screen printing technology to form side by side The conductive layer of each potassium ion selective working electrode, then print conductive carbon paste at one end of each conductive layer to form two side-by-side reaction electrodes, and print conductive carbon paste at the other end of the conductive layer to form two side-by-side contact electrodes;

[0063] (2) pretreat the surface of the reaction electrode with absolute ethanol, remove the floating dust on the surface, and make the surface clean and uniform;

[0064] (3) Weigh 3 mg of valinomycin and 1 mg of sodium tetraphenylborate in 1.5 mL of 3% PVC in tetrahydrofuran (3 g of PVC is added to 100 ml of tetrahydrofuran), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com