Method for preparing medical three-dimensional gradient netlike carbon fiber/ hydroxyapatite (HA)/ medical stone composite material

A composite material and carbon fiber technology, which is applied in medical science, anodic oxidation, prosthesis, etc., can solve the problems of low strength and poor toughness, and achieve the effect of good density and strength, less defects, and improved bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

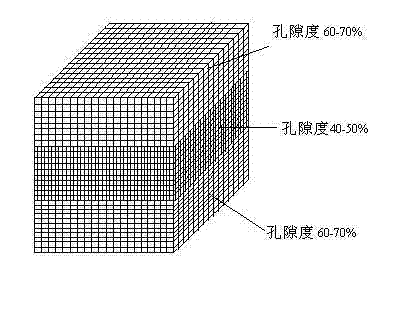

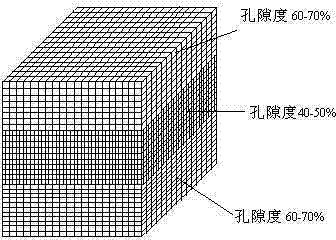

[0029] 1. Weave carbon fiber into a three-dimensional gradient network carbon fiber skeleton with a porosity of 70% at both ends and a porosity of 40% in the center;

[0030] 2. DC-pulse anodic oxidation and alkali treatment of three-dimensional gradient network carbon fiber skeleton; NH4 HCO 3 0.08mol / L, NH 4 h 2 PO 4 0.005mol / L, Ca(NO 3 ) 2 0.01mol / L configuration 3L electrolyte is poured into the electrolytic cell, the woven three-dimensional gradient network skeleton is immersed in the electrolyte as the anode, the graphite sheet is immersed in the electrolyte as the cathode, and a constant current is applied at both ends of the anode and cathode, DC The current density is 150mA / g, the pulse current density is 300mA / g, the main pulse width is 0.3s, the sub-pulse width is 0.1s, the pulse frequency is 1Hz, and the oxidation time is 1min. The sample after DC-pulse anodization was washed with deionized water, then soaked in 0.5mol / L NaOH solution at 80°C for 2 h, then ...

example 2

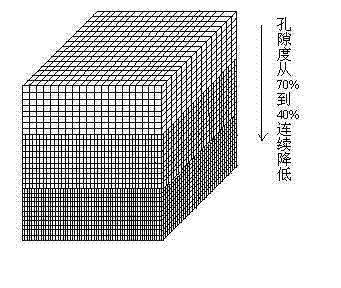

[0036] 1. The carbon fiber is woven into a three-dimensional gradient network porous skeleton, with a porosity of 65% at one end and 40% at the other end, and the pores present a continuous gradient decrease from the high-porosity end to the low-porosity end;

[0037] 2. Carry out DC-pulse anodizing, NH 4 HCO 3 0.08mol / L, NH 4 h 2 PO 4 0.005mol / L, Ca(NO 3 ) 2 0.01mol / L configuration 3L electrolyte is poured into the electrolytic cell, the woven three-dimensional gradient network skeleton is immersed in the electrolyte as the anode, the graphite sheet is immersed in the electrolyte as the cathode, and a constant current is applied at both ends of the anode and cathode, DC The current density is 50mA / g, the pulse current density is 100mA / g, the main pulse width is 0.3s, the sub-pulse width is 0.1s, the pulse frequency is 1Hz, and the oxidation time is 3min. The sample after DC-pulse anodization was washed with deionized water, then soaked in 0.5mol / L NaOH solution at 80...

example 3

[0043] 1. Weave carbon fiber into a three-dimensional gradient network carbon fiber skeleton with a porosity of 65% at both ends and a porosity of 50% in the center;

[0044] 2. Carry out DC-pulse anodizing, NH 4 HCO 3 0.08mol / L, NH 4 h 2 PO 4 0.005mol / L, Ca(NO 3 ) 2 0.01mol / L configuration 3L electrolyte is poured into the electrolytic cell, the woven three-dimensional gradient network skeleton is immersed in the electrolyte as the anode, the graphite sheet is immersed in the electrolyte as the cathode, and a constant current is applied at both ends of the anode and cathode, DC The current density is 100mA / g, the pulse current density is 200mA / g, the main pulse width is 0.3s, the sub-pulse width is 0.1s, the pulse frequency is 1Hz, and the oxidation time is 2min. The sample after DC-pulse anodization was washed with deionized water, then soaked in 0.5mol / L NaOH solution at 80°C for 2 h, then washed with deionized water and dried to obtain the modified three-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com