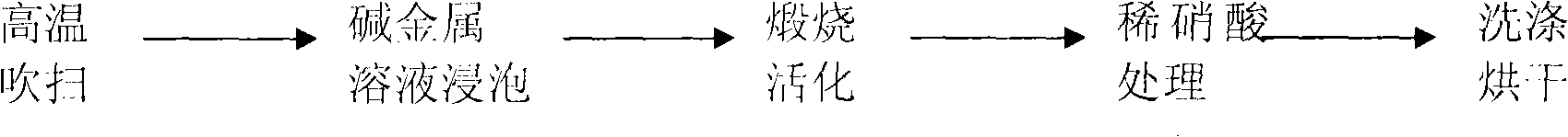

High temperature steam blowing - calcining activation - acid treating regeneration failure gamma - alumina microballoon

A technology of alumina and high temperature water vapor, applied in chemical/physical process, catalyst regeneration/reactivation, physical/chemical process catalyst, etc., can solve problems such as equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

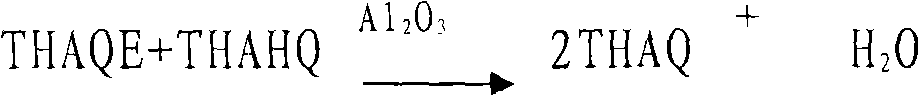

Method used

Image

Examples

Embodiment 1

[0017] Put 100 kg of invalid γ-alumina microspheres with an average particle size of 2mm into the tower reactor, and introduce high-temperature steam at 1.1MPa and 121°C from the top inlet of the tower reactor to purge the invalid γ-alumina microspheres. Aluminum microspheres for 20 hours; after cooling, immerse the γ-alumina microspheres in an aqueous sodium nitrate solution with a mass concentration of 5% for 6 hours; place the soaked invalid γ-alumina microspheres and the solution in a pore size of less than 0.5mm Filter out moisture and fine alumina powder, put it into a low-speed centrifuge, and dry it by centrifugation at 200 rpm for 10 minutes, then place it in an air-containing atmosphere and calcinate at 750°C for 3 hours; the calcined The gamma-alumina microspheres were naturally cooled to room temperature, soaked in a nitric acid solution with a mass concentration of 1% for 3 hours, and then filtered and dried;

[0018] Bake at 400°C for 2 hours in an air atmosphere...

Embodiment 2

[0020] Put 100 kg of invalid γ-alumina microspheres with an average particle size of 2mm into the tower reactor, and feed 1.3MPa, 194°C high-temperature steam from the top inlet of the tower reactor to purge the invalid γ-alumina microspheres. Aluminum microspheres for 12 hours; after cooling, immerse the γ-alumina microspheres in an aqueous solution of sodium carbonate with a mass concentration of 5% for 3 hours; place the soaked invalid γ-alumina microspheres and the solution in a pore size less than 0.5mm Filter out moisture and fine alumina powder, put it into a low-speed centrifuge, and dry it for 5 minutes at a speed of 400 rpm, then place it in an air-containing atmosphere and calcinate at 800°C for 2 hours; the calcined The gamma-alumina microspheres were naturally cooled to room temperature, soaked in a nitric acid solution with a mass concentration of 2.5% for 2 hours, and then filtered and dried;

[0021] Place in an air atmosphere and bake at 300°C for 2.5 hours, t...

Embodiment 3

[0023] Put 100 kg of invalid γ-alumina microspheres with an average particle size of 2mm into the tower reactor, and inject high-temperature steam at 300°C from the top inlet of the tower reactor to purge the invalid γ-alumina microspheres 12 hours; after cooling, immerse the γ-alumina microspheres in an aqueous sodium hydroxide solution with a mass concentration of 2% for 2 hours; place the soaked invalid γ-alumina microspheres and the solution in a filter with a pore size of less than 0.5mm net, filter out moisture and fine alumina powder, put it into a low-speed centrifuge, and centrifuge and dry it at a speed of 500 rpm for 5 minutes, then place it in an air-containing atmosphere and calcinate at 800 ° C for 2 hours; the calcined γ - Alumina microspheres were naturally cooled to room temperature, immersed in a nitric acid solution with a mass concentration of 3.0% for 1.5 hours, filtered and dried; placed in an air atmosphere at 300° C. for 3.0 hours, and naturally cooled t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap