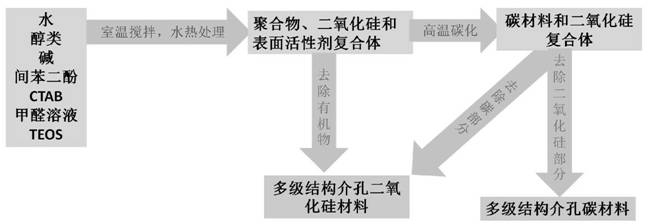

Method for simultaneously preparing multilevel-structure mesoporous silicon dioxide and carbon nano material

A technology of mesoporous silica and carbon nanomaterials, applied in the direction of silica, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of tedious and time-consuming methods and many steps, and achieve low cost, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

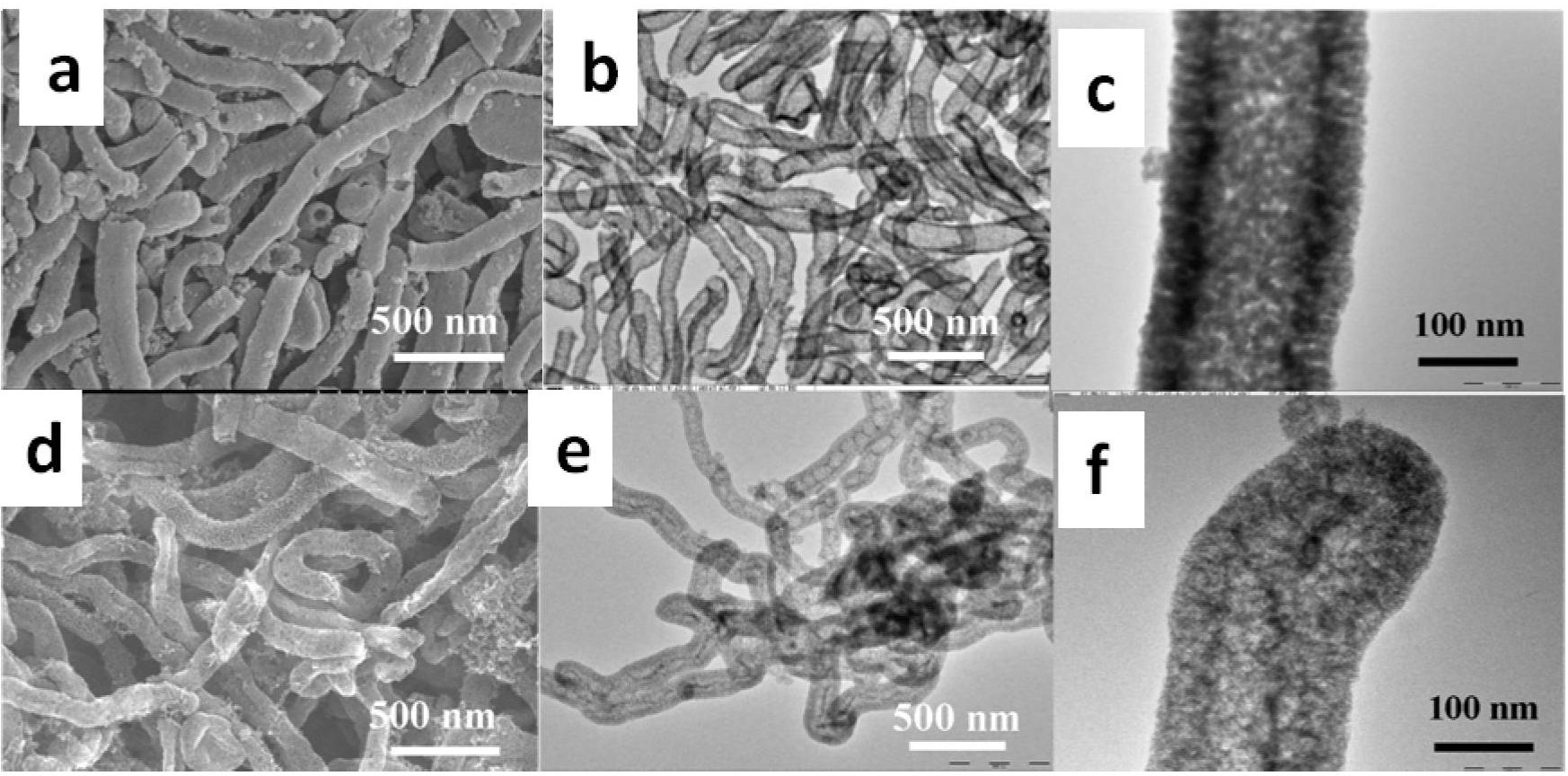

[0040] Preparation of tubular hollow mesoporous silica and carbon nanomaterials using the preparation system of the present invention

[0041] 1. Preparation of reaction solution

[0042] 1. In a reaction vessel, mix 4 mL of ethanol and 24 mL of water to prepare a reaction solvent; add 0.2 mL of ammonia solution with a mass concentration of 25% to 30%, 0.2 g of resorcinol and 0.2 g of CTAB into the reaction solvent.

[0043] 2. Stir the above mixture at room temperature for 30 min, add 0.28 mL formaldehyde solution and 1 mL TEOS.

[0044] 2. Preparation of composites of polymer phenolic resin, silicon dioxide and surfactant

[0045] Continue stirring the mixed solution prepared in step 1 at room temperature for 24 hours, then transfer the mixed solution to a sealed reaction vessel and perform hydrothermal treatment at a temperature of 100°C for 24 hours, then remove the supernatant to obtain a precipitate, and dry to obtain a solid powder; The obtained solid powder is a comp...

Embodiment 2

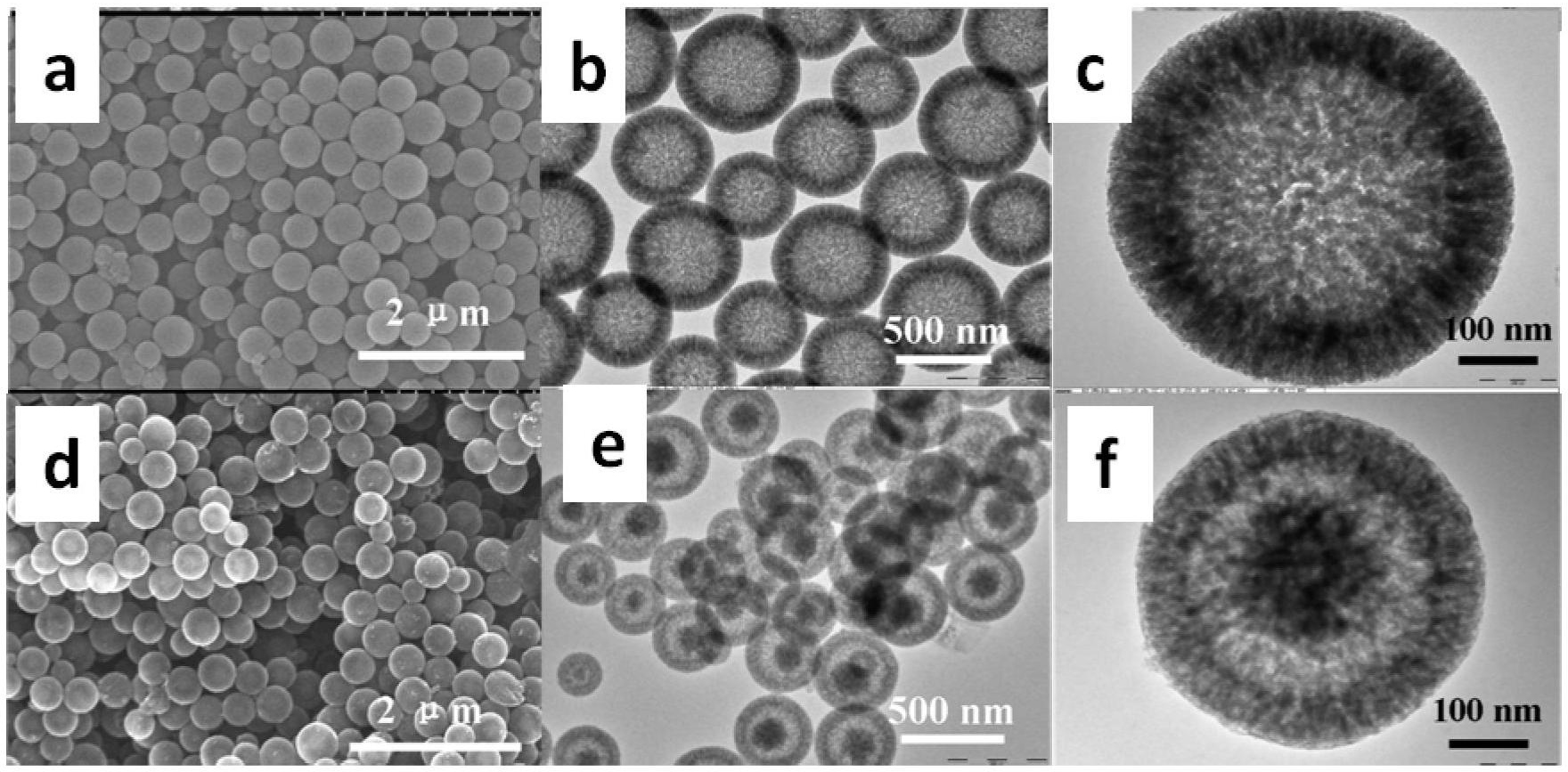

[0052] Preparation of hollow mesoporous silica microspheres and eggshell-yolk structure (Rattle-type) mesoporous carbon nanospheres using the preparation system of the present invention

[0053] 1. Preparation of reaction solution

[0054] 1. Same as Step 1 of Example 1, except that 8 mL of ethanol and 20 mL of water are mixed to prepare the reaction solvent.

[0055] 2. Same as step 1 of embodiment 1.

[0056] 2. Preparation of composites of polymer phenolic resin, silicon dioxide and surfactant

[0057] Same as Step 2 of Example 1.

[0058] 3. High-temperature carbonization to obtain a composite of carbon material and silicon dioxide

[0059] Same as Step 3 of Example 1.

[0060] 4. Preparation of hierarchical mesoporous silica or carbon nanomaterials

[0061] 1. Same as Step 4 of Example 1, except that the obtained hollow mesoporous silica microspheres. attached image 3 Among them, (a) is its SEM image, (b, c) is its TEM image.

[0062] 2. Same as Step 4 of Example...

Embodiment 3

[0064] The preparation system of the present invention is used to prepare irradiated mesoporous silica microspheres and hollow mesoporous carbon nanospheres.

[0065] 1. Preparation of reaction solution

[0066] 1. Same as Step 1 of Example 1, except that 12 mL of ethanol and 16 mL of water are mixed to prepare the reaction solvent.

[0067] 2. Same as step 1 of embodiment 1.

[0068] 2. Preparation of composites of polymer phenolic resin, silicon dioxide and surfactant

[0069] Same as Step 2 of Example 1.

[0070] 3. High-temperature carbonization to obtain a composite of carbon material and silicon dioxide

[0071] Same as Step 3 of Example 1.

[0072] 4. Preparation of hierarchical mesoporous silica or carbon nanomaterials

[0073] 1. Same as Step 4 of Example 1, the difference is that what is obtained is irradiated mesoporous silica microspheres. attached Figure 4 Among them, (a) is its SEM image, (b, c) is its TEM image.

[0074] 2. Same as Step 4 of Example 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com