Process for producing biogas by utilizing methane-straw gas coproduction device

A technology of biogas and biogas, applied in the direction of waste fuel, gas fuel, fuel, etc., can solve the problems of high operating cost, affecting fermentation efficiency, secondary environmental pollution, etc., and achieve the effect of improving gas production efficiency and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

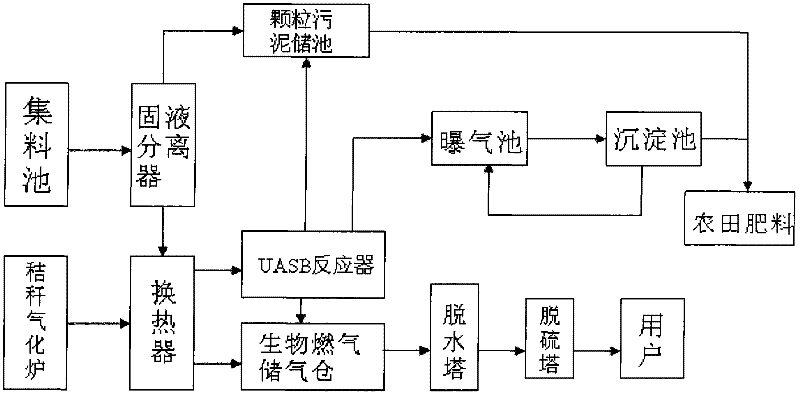

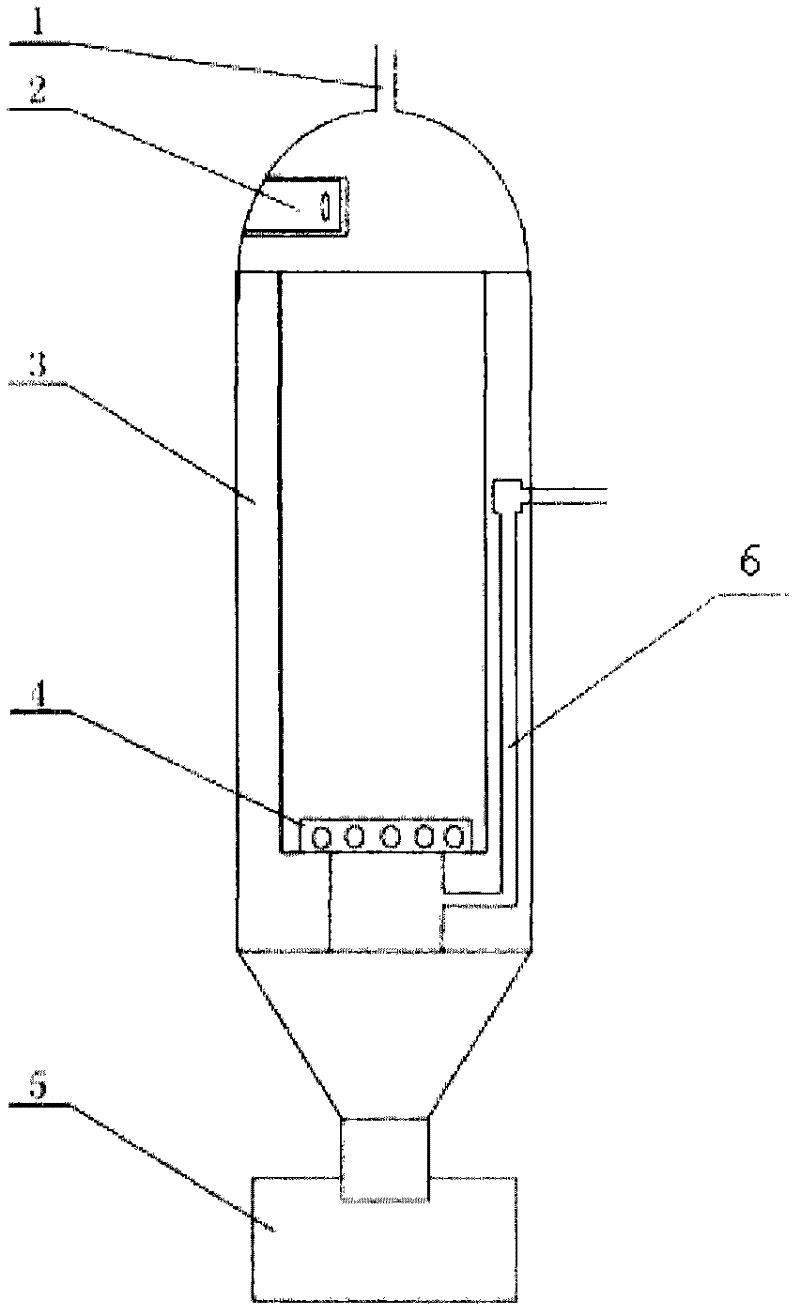

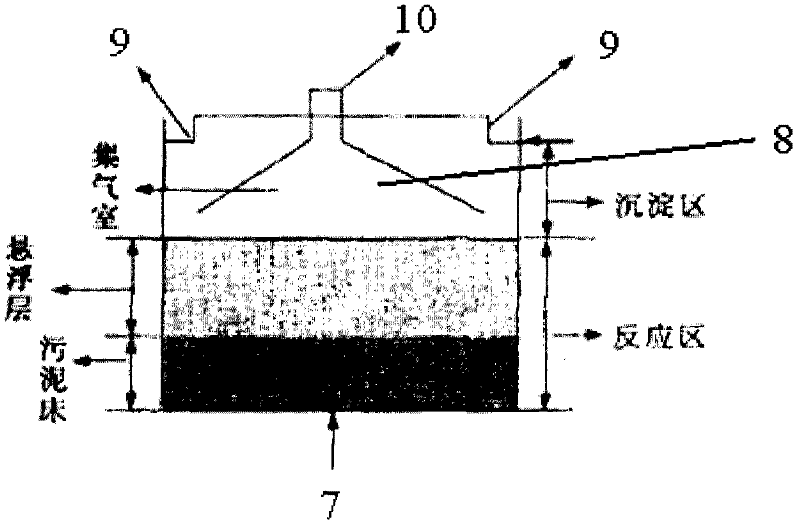

[0028] According to the accompanying drawings, the biogas and straw gas dual-gas cogeneration device of the present invention includes a collection tank, a solid-liquid separator, a heat exchanger, a UASB reactor, a granular sludge storage tank, an aeration tank, a sedimentation tank, and a straw gas Furnace, biogas gas storage tank, dehydration tower and desulfurization tower, among which UASB reactor includes organic waste water inlet, three-phase separator, liquid outlet and biogas outlet; straw gasifier includes exhaust pipe, fuel inlet, furnace body , grate, conical ash chamber, water seal pool and gas outlet; the biogas gas storage bin is a deformable elastic gas storage bin, which includes biogas inlet, gas inlet and mixed gas outlet.

[0029] Next refer to figure 1 , further detailing the production process of biogas and straw gas cogeneration. exist figur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap