Plastic metalizing method

A plastic metal roughening treatment technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of large environmental pressure, etc., and achieve the effect of saving resources, avoiding use and residue, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

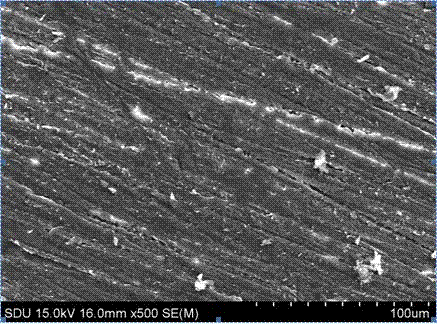

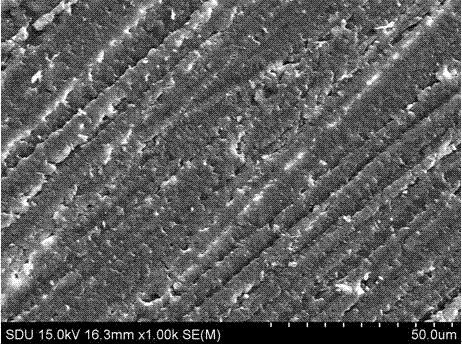

[0027] The basic process of pretreatment is: substrate mechanical treatment - water washing - internal stress relief - water washing - chemical degreasing - H 2 o 2 +H 2 SO 4 Chemical roughening—ultrasonic washing—drying—weighing—activation of gold nanoparticles.

[0028] Relief of internal stress is carried out at room temperature. Acetone solution is used for relieving internal stress, and the concentration of acetone solution is 250mL / L; the time for relieving internal stress is 20min.

[0029] Chemical degreasing is carried out at 40°C; the formula of the degreasing fluid used is:

[0030] NaOH 16g / L

[0031] Na 2 CO 3 18g / L

[0032] Na 3 PO 4 14 g / L.

[0033] h 2 o 2 +H 2 SO 4 Coarsening process: H 2 o 2 Concentration is 100mL / L, H 2 SO 4 The concentration is 400mL / L, the temperature is room temperature, and the time is 30min.

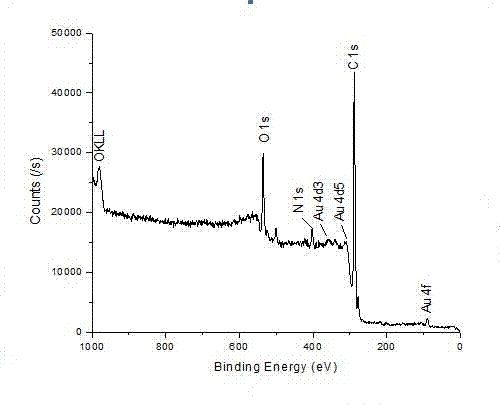

[0034] Activation process: the concentration of gold nanoparticles is 3.5×10 -4 mol / L, the temperature...

Embodiment 2

[0044] The basic flow of the pretreatment is the same as in Example 1.

[0045] Chemical degreasing is carried out at 50°C; the formula of the degreasing fluid used is:

[0046] NaOH 16g / L

[0047] Na 2 CO 3 18g / L

[0048] Na 3 PO 4 14 g / L.

[0049] h 2 o 2 +H 2 SO 4 Coarsening process: H 2 o 2 Concentration is 120mL / L, H 2 SO 4 The concentration is 420mL / L, the temperature is room temperature, and the time is 25min.

[0050] Activation process: the concentration of gold nanoparticles is 2.0×10 -4 mol / L, the temperature is normal temperature, and the time is 18 minutes.

[0051] The plating process is: 10g / L copper sulfate + 10mL / L formaldehyde + 45g / L potassium sodium tartrate + 1.2g / L nickel chloride + 5mg / L potassium ferrocyanide + 5g / L sodium carbonate to prepare the copper plating solution, the pH of the plating solution It is adjusted to 13.0, and the plating temperature is 45°C.

Embodiment 3

[0053] The basic flow of the pretreatment is the same as in Example 1.

[0054] Chemical degreasing is carried out at 45°C; the formula of the degreasing fluid used is:

[0055] NaOH 16g / L

[0056] Na 2 CO 3 18g / L

[0057] Na 3 PO 4 14 g / L.

[0058] h 2 o 2 +H 2 SO 4 Coarsening process: H 2 o 2 Concentration is 130mL / L, H 2 SO 4 The concentration is 450mL / L, the temperature is room temperature, and the time is 20min.

[0059] Activation process: the concentration of gold nanoparticles is 5.0×10 -4 mol / L, the temperature is normal temperature, and the time is 15 minutes.

[0060] The plating process is: 12g / L copper sulfate + 15mL / L formaldehyde + 48g / L potassium sodium tartrate + 1.5g / L nickel chloride + 7mg / L potassium ferrocyanide + 7g / L sodium carbonate to prepare the copper plating solution, the pH of the plating solution Adjusted to 13.2, the plating temperature is 47 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com