Preparation method of metal photonic crystal material

A technology of metal photonic crystal and volume ratio, which is applied in the direction of polycrystalline material growth, crystal growth, chemical instruments and methods, etc., can solve the problems of limiting the preparation of large-area metal photonic crystal materials, and achieve easy control of reaction, simple operation, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

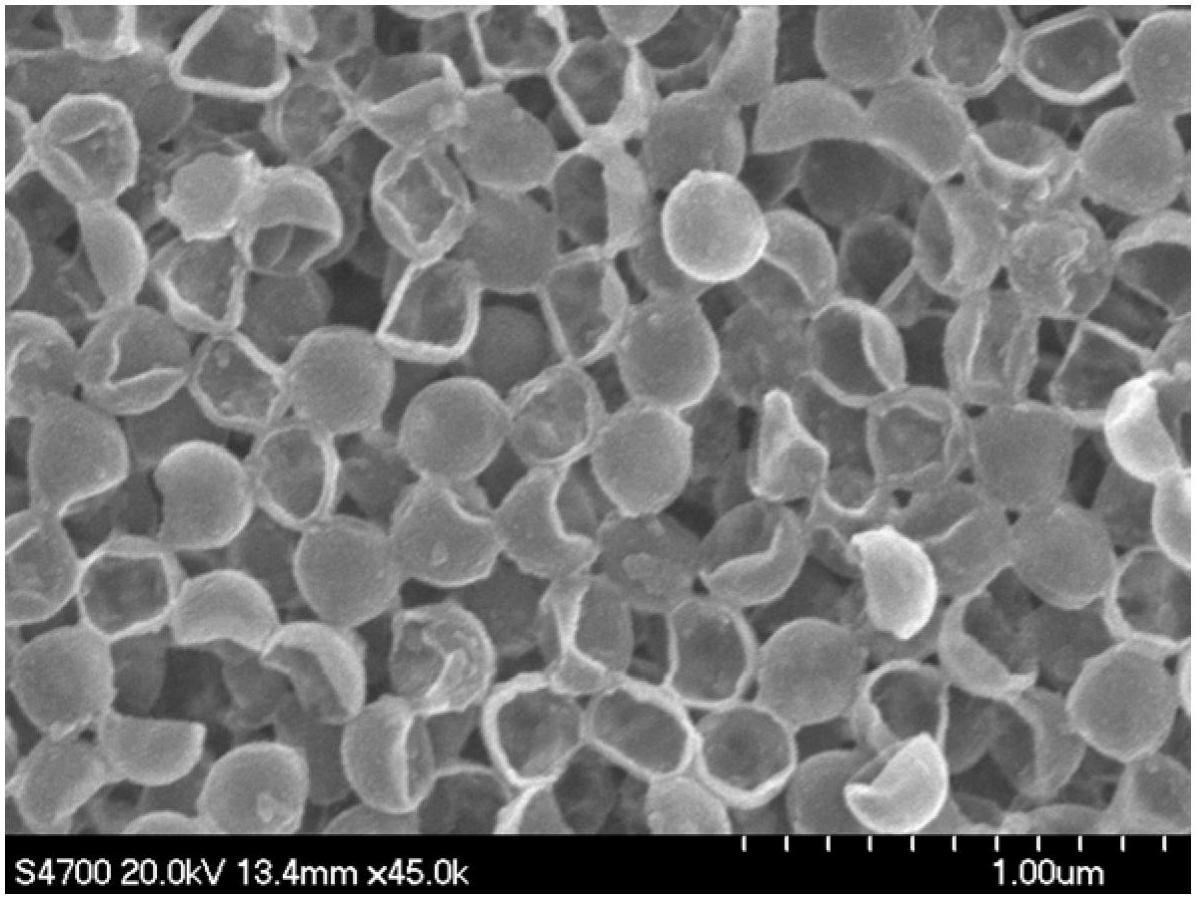

[0024] Embodiment 1: the preparation method of platinum photonic crystal, the steps are as follows:

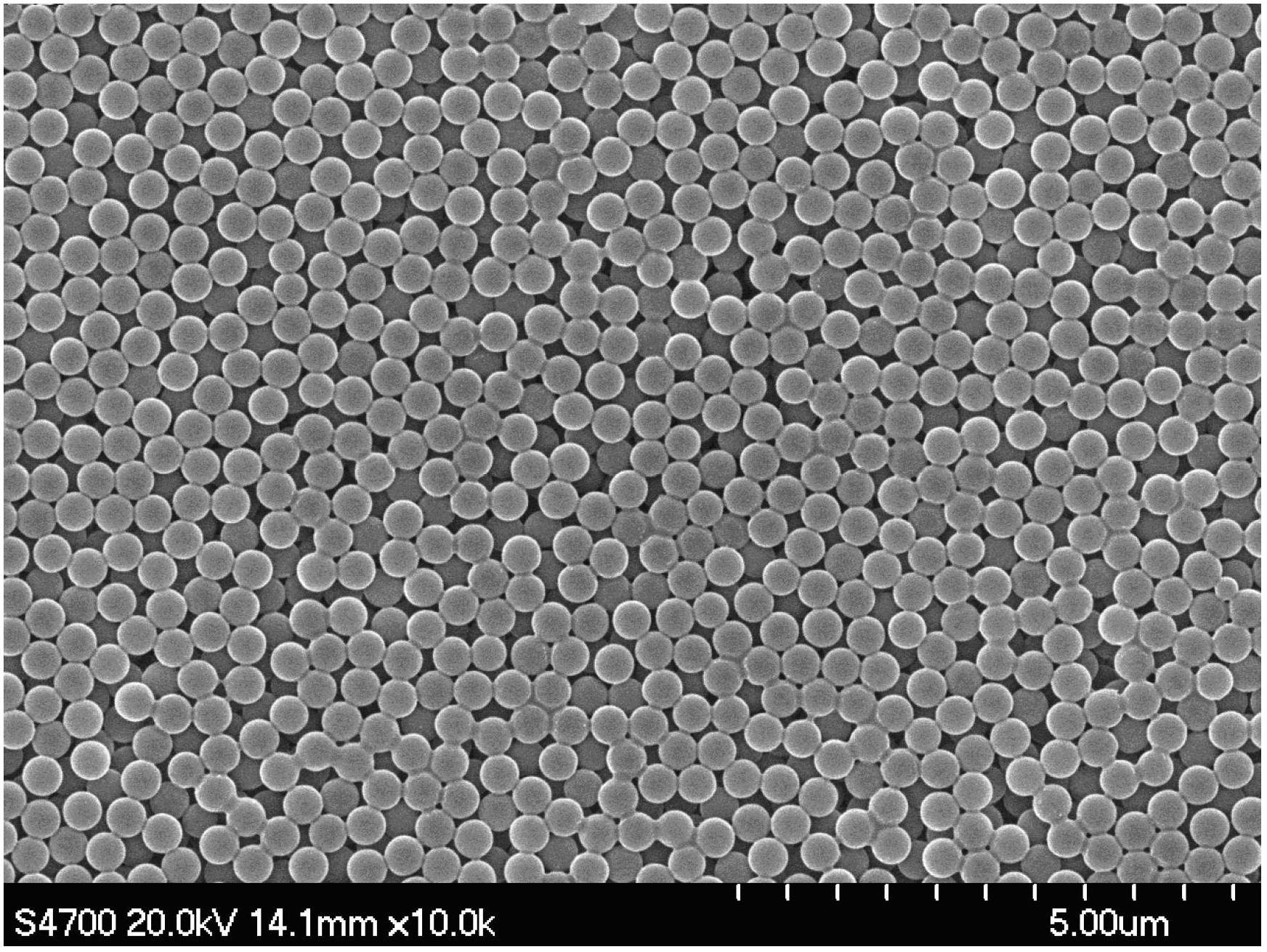

[0025] 1) Polystyrene microspheres were synthesized by soap-free emulsion polymerization. Styrene was added to a mixed solution of water and ethanol, where the volume ratio of styrene, water and ethanol was 1:6:14, and nitrogen was used for protection. Set the temperature at 71° C., and add a 0.02 g / ml potassium persulfate solution equal to the volume of styrene added to the system after the temperature stabilizes to carry out the reaction.

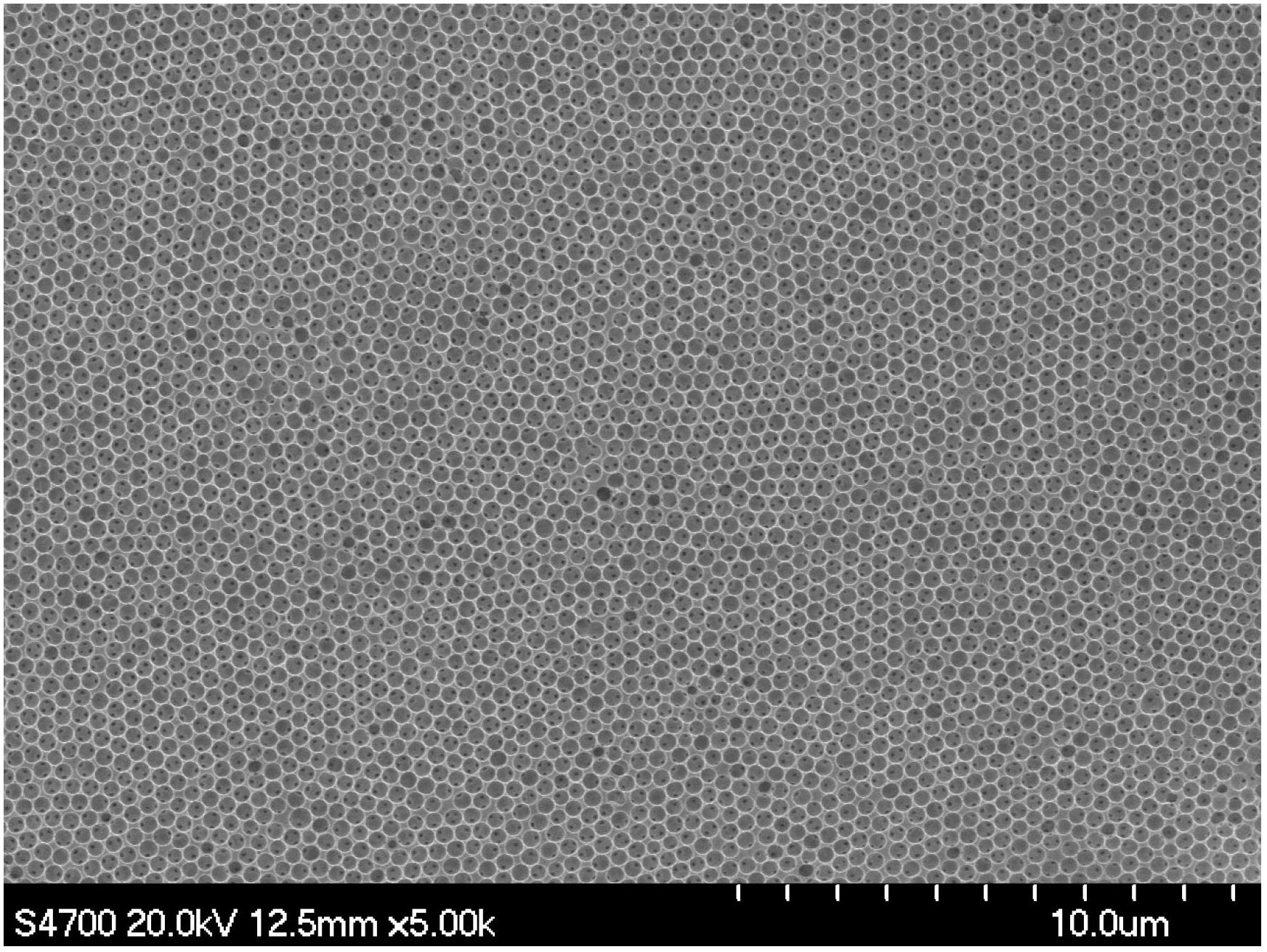

[0026] 2) Prepare the silicon dioxide precursor solution with tetraethyl orthosilicate, ethanol, and 0.1M hydrochloric acid in a mass ratio of 1:1.5:1. Then it is mixed with the polystyrene microsphere emulsion prepared in 1) into the solution, wherein the volume ratio of the polystyrene microsphere emulsion and the precursor solution is 100:1. and placed in an oven at 65° C. to grow for 2 days, and then calcined at 450° C. for 5 hours t...

Embodiment 2

[0031] The preparation method of platinum photonic crystal, the steps are as follows:

[0032] 1) Polystyrene microspheres were synthesized by soap-free emulsion polymerization. Styrene was added to a mixed solution of water and ethanol, where the volume ratio of styrene, water and ethanol was 1:6:14, and nitrogen was used for protection. Set the temperature at 71° C., and add a 0.02 g / ml potassium persulfate solution equal to the volume of styrene added to the system after the temperature stabilizes to carry out the reaction.

[0033] 2) Prepare the silicon dioxide precursor solution with tetraethyl orthosilicate, ethanol, and 0.1M hydrochloric acid in a mass ratio of 1:1.5:1. Then it is mixed with the polystyrene microsphere emulsion prepared in 1) into the solution, wherein the volume ratio of the polystyrene microsphere emulsion and the precursor solution is 100:1. and placed in an oven to grow for 2 days, and then calcined at 450° C. for 5 hours to remove polystyrene mic...

Embodiment 3

[0037] Embodiment 3 The preparation method of gold photonic crystal, the steps are as follows:

[0038] 1) Polystyrene microspheres were synthesized by soap-free emulsion polymerization. Styrene was added to a mixed solution of water and ethanol, where the volume ratio of styrene, water and ethanol was 1:6:14, and nitrogen was used for protection. Set the temperature at 71° C., and add a 0.02 g / ml potassium persulfate solution equal to the volume of styrene added to the system after the temperature stabilizes to carry out the reaction.

[0039] 2) Prepare the silicon dioxide precursor solution with tetraethyl orthosilicate, ethanol, and 0.1M hydrochloric acid in a mass ratio of 1:1.5:1. Then it is mixed with the polystyrene microsphere emulsion prepared in 1) into the solution, wherein the volume ratio of the polystyrene microsphere emulsion and the precursor solution is 100:1. and placed in an oven to grow for 3 days, and then calcined at 450° C. for 5 hours to remove polyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com