Highly adhesive thermoplastic resin film

A thermoplastic resin film, easy-adhesive technology, applied in the direction of heat-activated film/sheet, synthetic resin layered products, adhesives, etc., can solve problems such as lack of adhesion, achieve excellent adhesion resistance, excellent heat and humidity resistance , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

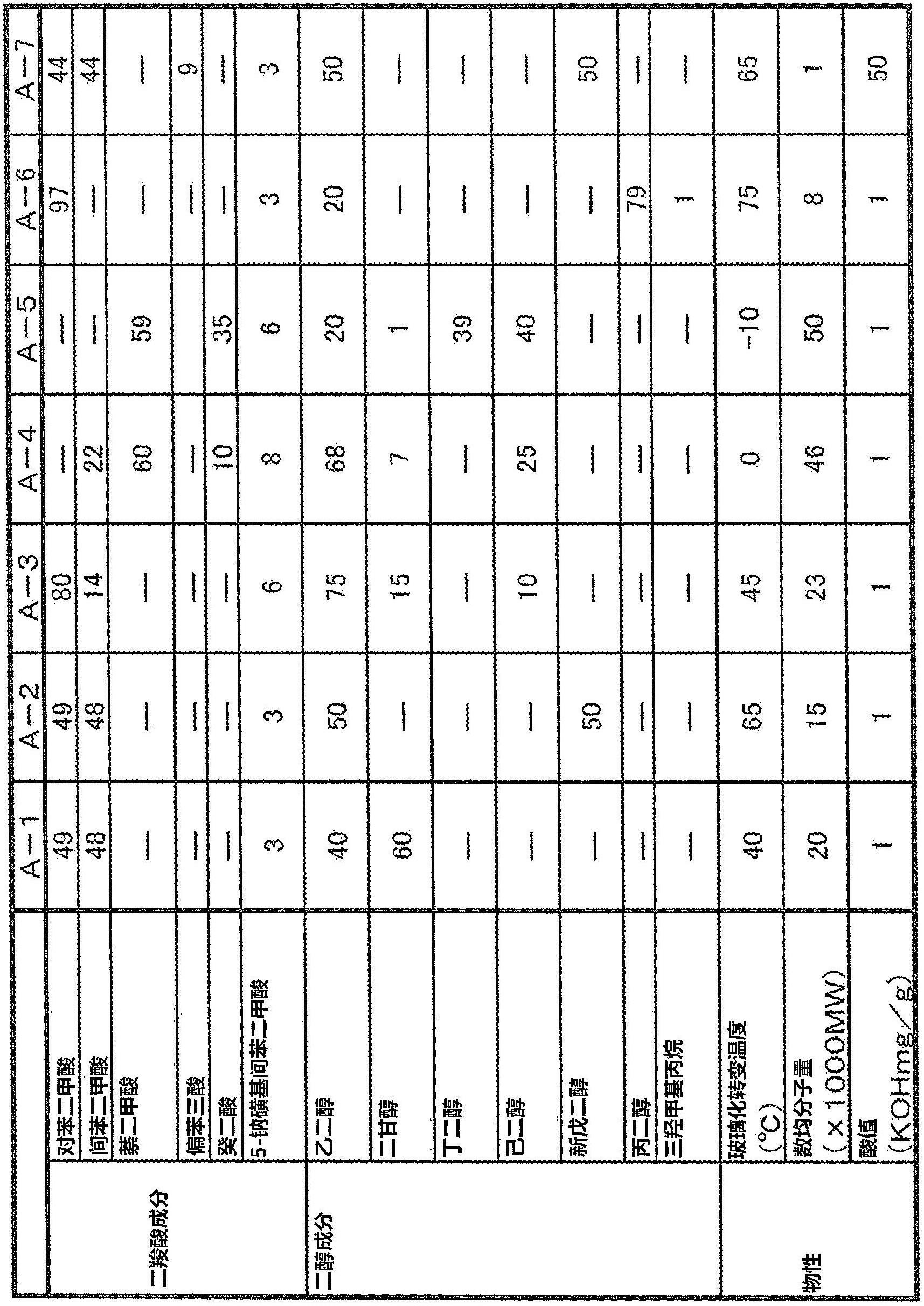

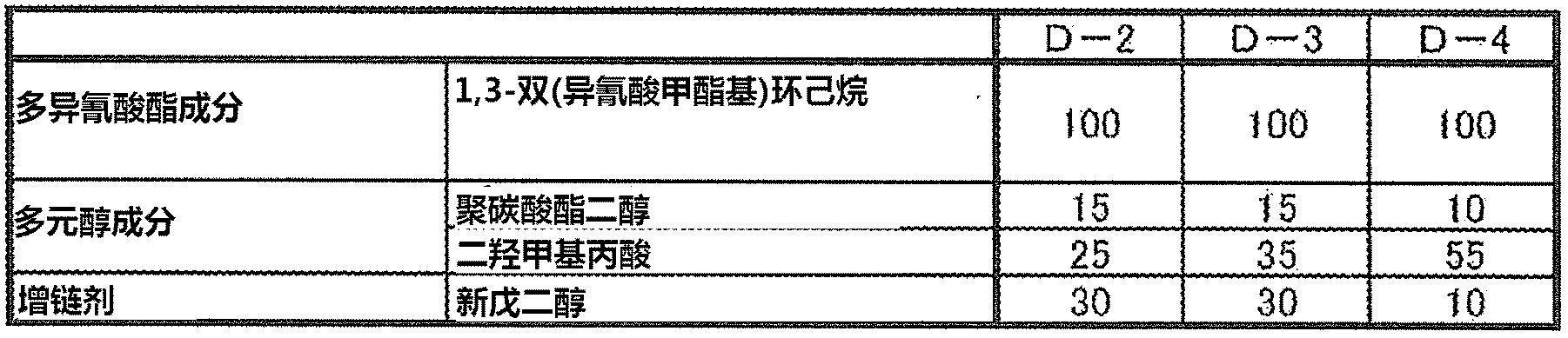

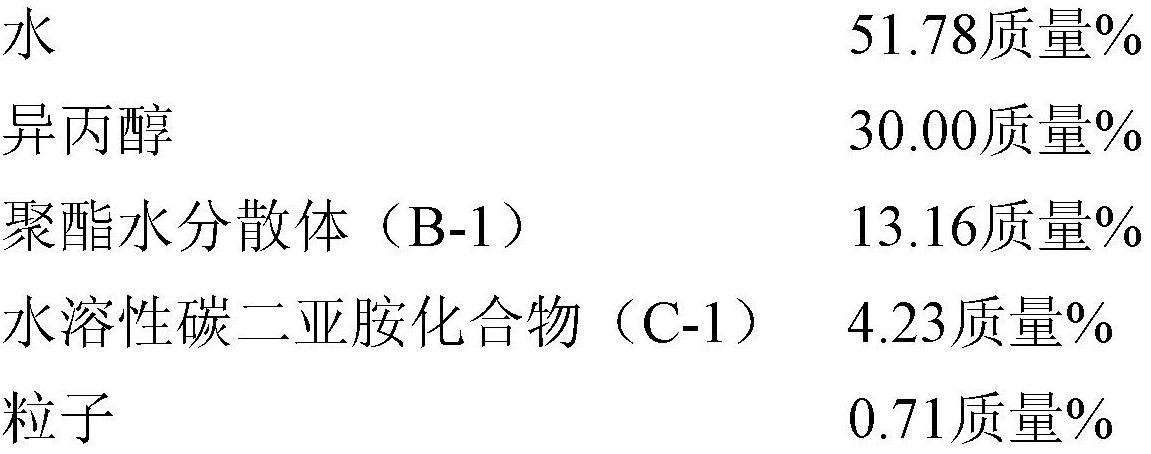

[0204] (1) Preparation of coating liquid

[0205] The following coating agents were mixed to prepare a coating liquid. The number average molecular weight of the polyester resin was 20,000.

[0206]

[0207] (Silica sol with an average particle diameter of 40 nm and a solid content concentration of 40% by mass)

[0208] Particles 0.07% by mass

[0209] (Silica sol with an average particle diameter of 450 nm, a solid content concentration of 40% by mass)

[0210] Surfactant 0.05% by mass

[0211] (Silicon-based, solid content concentration 100% by mass)

[0212] (2) Manufacture of easy-adhesive polyester film

[0213]As a film base polymer, PET resin pellets having an intrinsic viscosity of 0.62 dl / g and substantially free of particles were dried under a reduced pressure of 133 Pa at 135° C. for 6 hours. Then, it was supplied to an extruder, melted and extruded into a sheet at about 280° C., and rapidly cooled on a rotating cooling metal roll maintained at a surface te...

Embodiment 2

[0237] Except having changed the coating liquid into the following coating liquid, it carried out similarly to Example 1, and obtained the easily-adhesive polyester film and laminated polyester film.

[0238]

[0239] (Silica sol with an average particle diameter of 40 nm and a solid content concentration of 40% by mass)

[0240] Particles 0.07% by mass

[0241] (Silica sol with an average particle diameter of 450 nm, a solid content concentration of 40% by mass)

[0242] Surfactant 0.05% by mass

[0243] (Silicon-based, solid content concentration 100% by mass)

Embodiment 3

[0245] Except having changed the coating liquid into the following coating liquid, it carried out similarly to Example 1, and obtained the easily-adhesive polyester film and laminated polyester film.

[0246]

[0247] (Silica sol with an average particle diameter of 40 nm and a solid content concentration of 40% by mass)

[0248] Particles 0.07% by mass

[0249] (Silica sol with an average particle diameter of 450 nm, a solid content concentration of 40% by mass)

[0250] Surfactant 0.05% by mass

[0251] (Silicon-based, solid content concentration 100% by mass)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com