Fibroin-controlled alpha type ferric oxide nano material and preparation method thereof

A technology of ferric oxide and nanomaterials, which is applied in the field of nanomaterials and natural polymer materials, can solve the problems of insufficient system and sufficient, time-consuming, energy-consuming, high cost, complicated method and process, and achieve mild conditions and easy operation , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

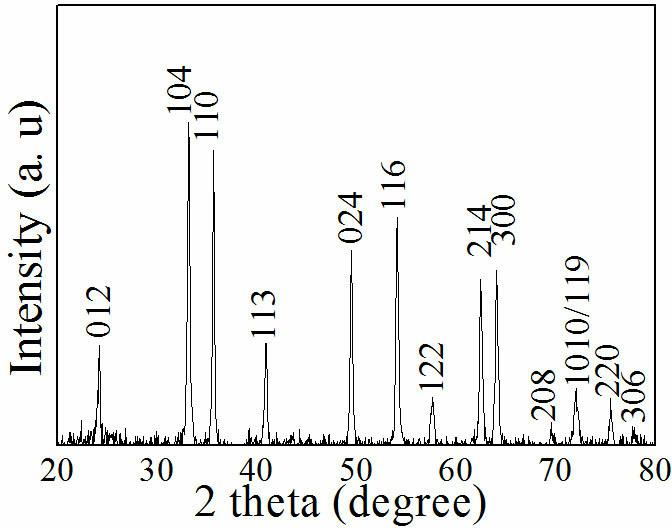

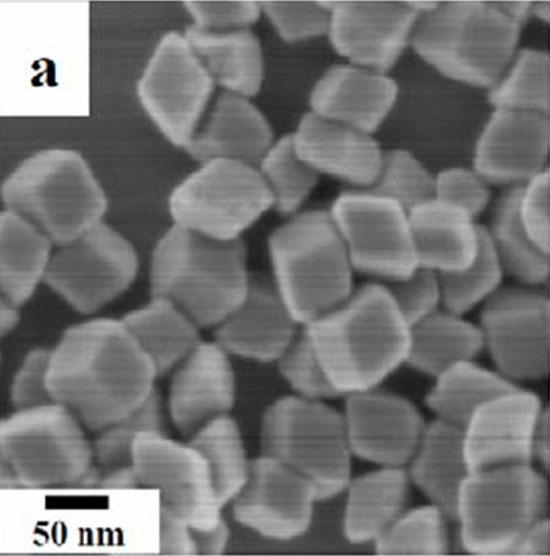

[0024] Example 1: 0.135g of anhydrous ferric chloride was added to about 50mL of regenerated silk protein aqueous solution with a mass concentration of 0.01% under stirring, so that the molar concentration of ferric chloride was 0.01mol / L. Continue stirring for 5 minutes to fully dissolve ferric chloride to obtain a light yellow clear solution. Transfer the pale yellow clear solution to a 100mL polytetrafluoroethylene-lined stainless steel reactor, seal and heat up to 160 o C reacted for 10h. After the reaction was finished, the product was cooled to room temperature, then the solution in the reaction system was centrifuged, and the precipitate was washed 4 times with absolute ethanol and deionized water, and then washed at 50 o C drying for 20 hours, the nearly cubic α-type ferric oxide nanomaterial with a particle size of 50nm can be obtained.

Embodiment 2

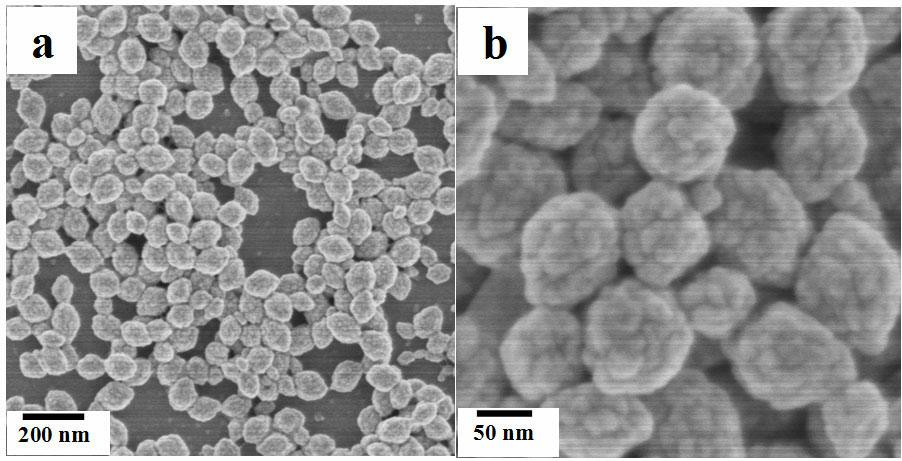

[0025] Example 2: 0.135g of anhydrous ferric chloride was added to about 50mL of regenerated silk protein aqueous solution with a mass concentration of 0.1% under stirring, so that the molar concentration of ferric chloride was 0.01mol / L. Continue to stir for 10 minutes to fully dissolve ferric chloride to obtain a light yellow clear solution. Transfer the pale yellow clear solution to a 100mL polytetrafluoroethylene-lined stainless steel reactor, seal and heat up to 160 o C reacted for 20h. After the reaction is finished, the product is cooled to room temperature, then the solution in the reaction system is centrifuged, and the precipitate is washed 5 times with absolute ethanol and deionized water, and then washed at 90 o C dried for 10 hours to obtain spherical α-type ferric oxide nanomaterials with a particle size of 50 nm.

Embodiment 3

[0026] Example 3: 0.27g of anhydrous ferric chloride was added to about 50mL of regenerated silk protein aqueous solution with a mass concentration of 0.5% under stirring, so that the molar concentration of ferric chloride was 0.02mol / L. Continue to stir for 20 minutes to fully dissolve ferric chloride to obtain a light yellow clear solution. Transfer the pale yellow clear solution to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, seal and heat up to 180 o C reacted for 5h. After the reaction was finished, the product was cooled to room temperature, then the solution in the reaction system was centrifuged, the precipitate was washed twice with absolute ethanol and deionized water, and then washed at 100 o C drying for 8 hours to obtain a spherical α-type ferric oxide nanomaterial with a particle size of 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com