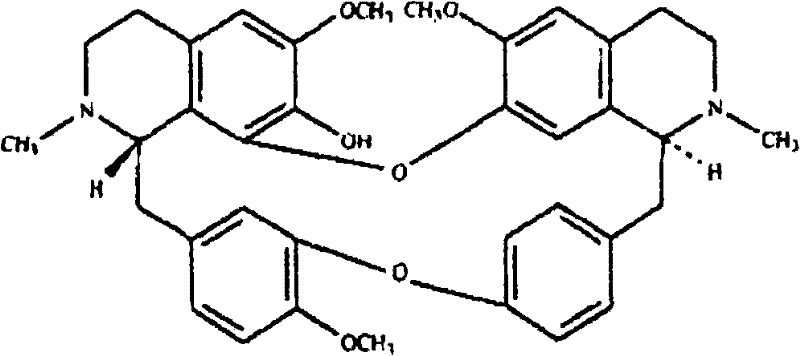

Purification method of fangchinoline

A technology of tetrandrine and its purification method, which is applied in the field of refining tetrandrine by ODS reversed-phase silica gel method, can solve the problems of large solvent consumption, etc., and achieve the effects of high product purity, easy operation, and simple operation of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 1 kg of Fangji medicinal material powder, add 5 L of 40% methanol solution to reflux and extract twice, extract for 1 hour each time, recover the solvent from the extract until it has no alcohol smell, add hydrochloric acid to adjust the pH to 2, filter the acid solution, add sodium hydroxide to adjust to pH9, add 1 times the amount of chloroform for extraction, let stand to separate layers, release the chloroform layer, then take 450g of ODS silica gel to pack into the column, take another 50g of ODS silica gel and chloroform layer to mix the sample, evaporate the solvent, put it on the column, and elute with 60% methanol aqueous solution , collected the eluent, concentrated and dried to obtain 3.8 g of the product, with a content of 99.1%.

Embodiment 2

[0023] Take 1 kg of Fangji medicinal material powder, add 12L of 70% ethanol solution to reflux extraction 4 times, extract 3 hours each time, recover the solvent from the extract until it has no alcohol smell, add sulfuric acid to adjust the pH to 4, filter the acid solution, add potassium hydroxide to adjust to pH 9, add 3 times the amount of chloroform for extraction, let stand to separate layers, release the chloroform layer, then take 1000g ODS silica gel to pack into the column, take another 125g ODS silica gel and chloroform layer to mix the sample, evaporate the solvent, put it on the column, and elute with 55% acetonitrile aqueous solution , collected the eluent, concentrated and dried to obtain 3.5 g of the product, with a content of 99.3%.

Embodiment 3

[0025] Take 5 kg of Fangji medicinal material powder, add 40 L of 50% ethanol solution to reflux and extract 3 times, extract for 2 hours each time, recover the solvent from the extract until it has no alcohol smell, add formic acid to adjust the pH to 3, filter the acid solution, and add sodium hydroxide to adjust to pH 10, add 2 times the amount of chloroform for extraction, let stand to separate layers, release the chloroform layer, then take 3kg ODS silica gel to pack into the column, take another 300g ODS silica gel and chloroform layer to mix the sample, evaporate the solvent, put it on the column, and elute with 58% methanol aqueous solution , collected the eluate, concentrated and dried to obtain 18.7 g of the product, with a content of 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com