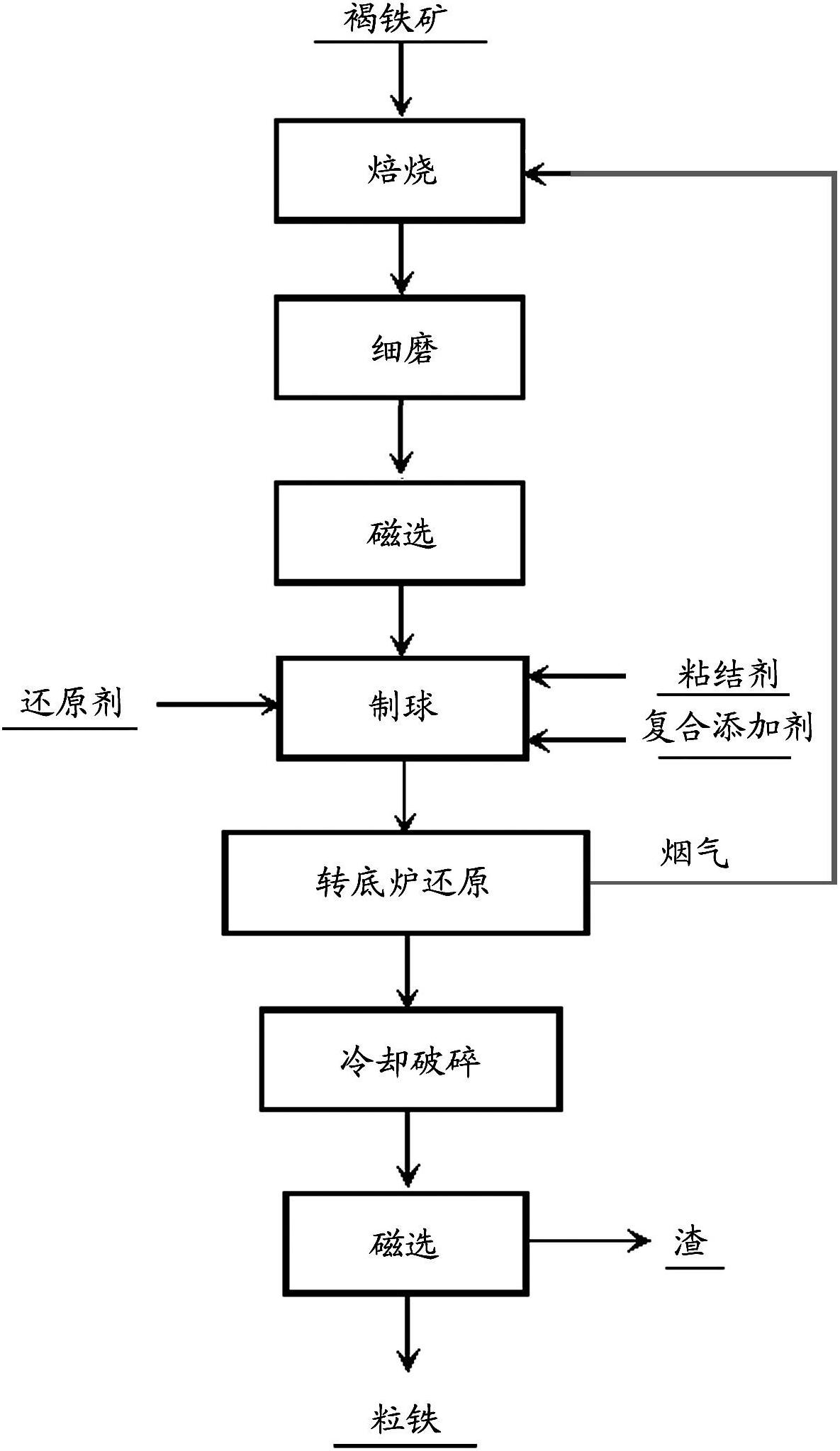

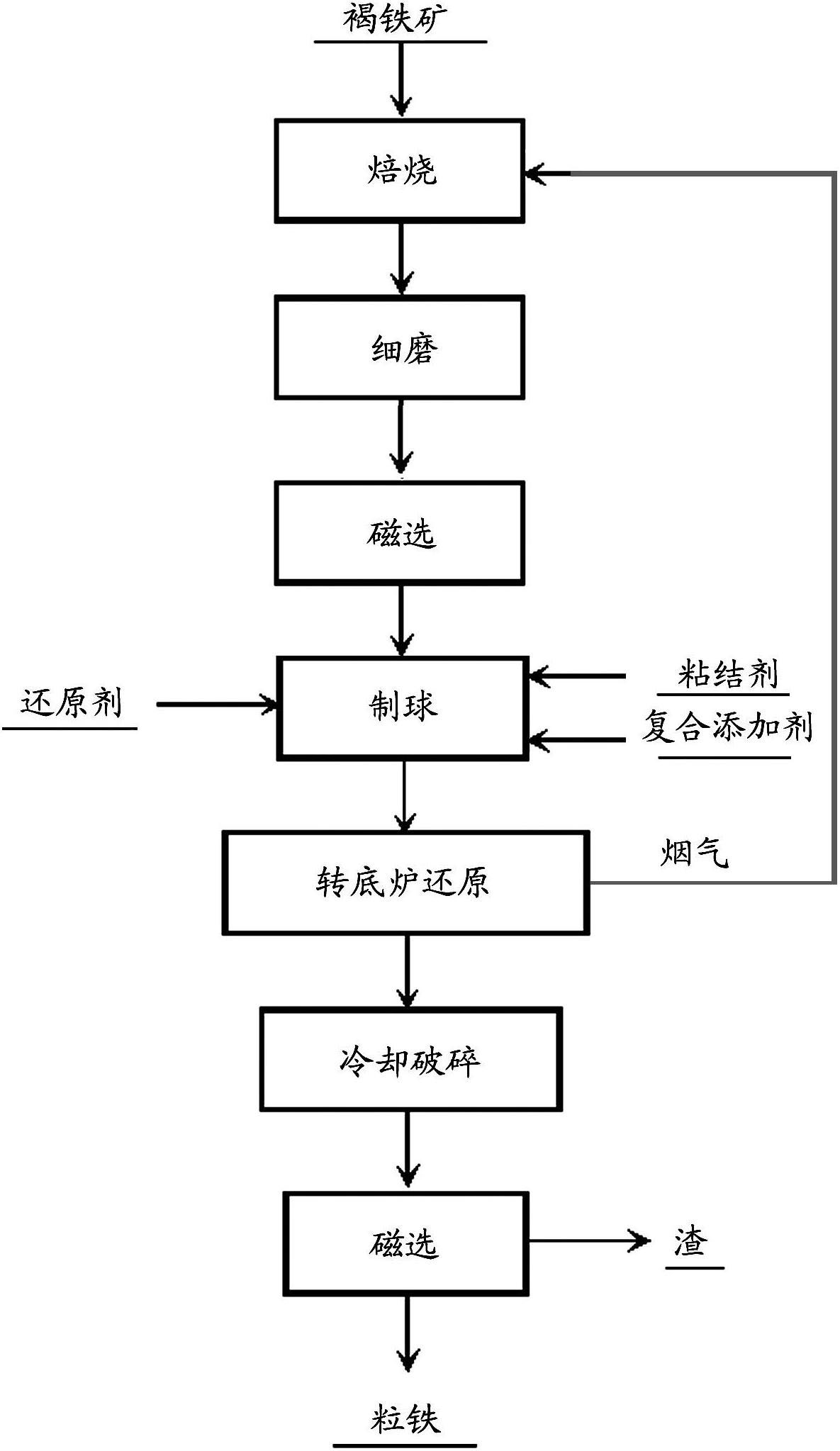

Method for producing granular iron by magnetically roasting and reducing low-quality limonite with rotary hearth furnace

A technology of magnetizing roasting and limonite, which is applied in the field of metallurgy to achieve the effects of low fuel consumption, short reduction time and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In Example 1, the chemical composition of limonite is as follows: TFe (full iron) 40.33%, FeO 0.64%, Fe 2 o 3 56.94%, SiO 2 16.20%, Al 2 o 3 4.01%, CaO 1.15%, MgO 0.48%, MnO 4.62%, Lol (burning loss) 15.96%.

[0028] A certain amount of limonite with the above chemical composition is reduced and roasted with flue gas from the rotary hearth furnace. The roasted ore is finely ground to below 30 mesh, and then enriched by magnetic separation to obtain the enriched ore. Then, based on the weight of the enriched ore after magnetic separation and enrichment, add about 25% of pitch coke as carbonaceous reducing agent, about 27% of quicklime and fluorite as composite additives and about 4% of The syrup is used as a binder and mixed evenly, pressed into pellets with a diameter of 10-40mm by a double-roller ball press, and dried at about 300°C for about 2 hours. Subsequently, the dried pellets are quickly reduced in a rotary hearth furnace, the reduction temperature is 1...

Embodiment 2

[0030] In Example 2, the chemical composition of limonite is as follows: TFe 46.60%, FeO 1.23%, Fe 2 o 3 65.2%, SiO 2 8.84%, Al 2 o 3 5.97%, CaO 1.29%, MgO 1.71%, MnO 0.89%, Lol (burning loss) 14.87%.

[0031] A certain amount of limonite with the above-mentioned chemical composition is reduced and roasted with the flue gas of the rotary hearth furnace. The ore is finely ground to below 30 mesh, and then enriched by magnetic separation to obtain enriched ore. Then, based on the weight of the enriched ore after magnetic separation and enrichment, add about 27% charcoal as carbonaceous reducing agent, about 15% quicklime and fluorite as composite additives and about 6% bitumen to the enriched ore Use as a binder and mix evenly, press it into pellets with a diameter of 10-40mm with a double-roller ball press, and dry at about 350°C for about 3 hours. Subsequently, the dried pellets are quickly reduced in a rotary hearth furnace, the reduction temperature is 1450°C, and th...

Embodiment 3

[0033]In Example 3, the chemical composition of limonite is as follows: TFe 42.83%, FeO 0.86%, Fe 2 o 3 60.23%, SiO 2 10.68%, Al 2 o 3 4.53%, CaO 0.79%, MgO 2.13%, MnO 1.56%, Lol 19.22%.

[0034] A certain amount of limonite with the above chemical composition is reduced and roasted with flue gas from the rotary hearth furnace. The ore is finely ground to below 30 mesh, and then enriched by magnetic separation to obtain enriched ore. Then, based on the weight of the enriched ore after magnetic separation and enrichment, add about 30% of anthracite as carbonaceous reducing agent, about 8% of quicklime and fluorite as composite additives and about 10% of syrup to the enriched ore Use asphalt as a binder and mix evenly, use a disc pelletizer to press into pellets with a diameter of 10-40mm, and dry at about 400°C for about 1 hour. Subsequently, the dried pellets are quickly reduced in a rotary hearth furnace, the reduction temperature is 1250°C, and the reduction time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com