Environment-friendly NOx selective catalytic reduction catalyst and preparation method thereof

An environmentally friendly and selective technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve insufficient high temperature activity, poor resistance to sulfur poisoning, poisoning HC and other problems, to achieve the effect of efficient catalytic removal of nitrogen oxides, good SO2 poisoning ability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

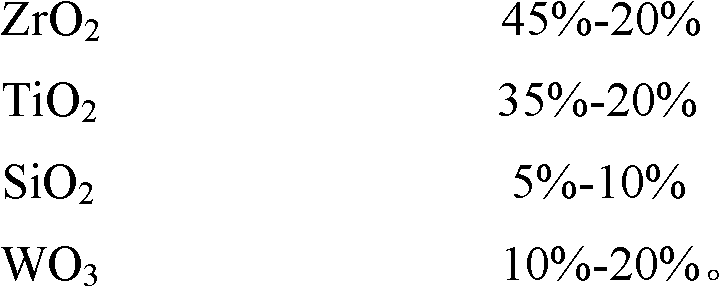

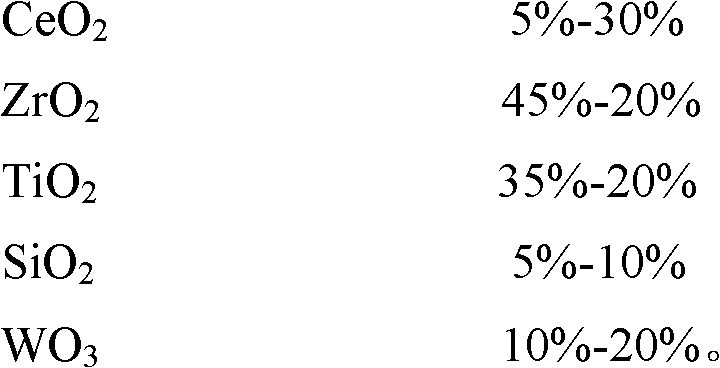

Method used

Image

Examples

Embodiment 1

[0028] Get 12.62g cerous nitrate Ce (NO 3 ) 3 ·6H 2 O, 97.60g zirconium oxynitrate ZrO(NO 3 ) 2 2H 2 O and 85.87g titanyl sulfate TiOSO 4 Dissolve in 555mL deionized water, the molar concentration is [Ce+Zr+Ti]=1.5mol / L, use 5mol / LNH under rapid stirring 3 ·H 2 O for precipitation, adjust the pH to 8, add 0.3g of polyethylene glycol, fully stir for 10min, let stand at room temperature for 1h, and age at 60°C for 3h; take 11.26g of ammonium paratungstate 5(NH 4 ) 2 O·12WO 3 ·5H 2 O and 10.16 g sodium silicate Na 2 SiO 3 , dissolved in 84mL deionized water, the molar concentration is [Si+W]=1.5mol / L, use 5mol / L NH under vigorous stirring 3 ·H 2 O for precipitation, the titration end point is pH 9, add polyethylene glycol 0.2g, stir thoroughly for 30min, let stand at room temperature for 1h, and age at 80°C for 3h; stir and mix the two suspensions thoroughly, and carry out the second phase at 60°C. Secondary aging, the aging time is 10h. Use vacuum filtration to ob...

Embodiment 2

[0033] Get 37.85g cerous nitrate Ce (NO 3 ) 3 ·6H 2 O, 21.69g zirconium oxynitrate ZrO(NO 3 ) 2 2H 2 O and 24.53g titanyl sulfate TiOSO 4Dissolve in 588mL deionized water, the molar concentration is [Ce+Zr+Ti]=0.5mol / L, use 4mol / L ammonium bicarbonate for precipitation under rapid stirring, adjust the pH to 10, add polyethylene glycol 0.5g, fully Stir for 30min, stand at room temperature for 1h, age at 80°C for 3h; take 11.26g of paratungstic acid 5(NH 4 ) 2 O·12WO 3 ·5H 2 O and 10.16 g sodium silicate Na 2 SiO 3 , dissolved in 252mL deionized water, the molar concentration is [Si+W]=0.5mol / L, use 4mol / LNH under vigorous stirring 3 ·H 2 O for precipitation, the titration end point is pH 9, add polyethylene glycol 0.4g, stir thoroughly for 10min, let stand at room temperature for 1h, age at 60°C for 3h; Secondary aging, the aging time is 12h. Use vacuum filtration to obtain a precipitate, and use deionized water to wash the precipitate until the filtrate is neutra...

Embodiment 3

[0035] Get 50.47g cerous nitrate Ce (NO 3 ) 3 ·6H 2 O, 65.07g zirconium oxynitrate ZrO(NO 3 ) 2 2H 2 O and 62.33g of titanyl sulfate were dissolved in 336mL of deionized water with a molar concentration of [Ce+Zr+Ti]=2mol / L. Under rapid stirring, 3mol / L ammonium bicarbonate was used for precipitation, the pH was adjusted to 12, and polyethylene Diol 2g, fully stirred for 20min, left at room temperature for 1h, aged at 80°C for 3h; took 19.14g of paratungstic acid 5(NH 4 ) 2 O·12WO 3 ·5H 2 O and 34.53 g sodium silicate Na 2 SiO 3 , dissolved in 159mL deionized water, the molar concentration is [Si+W]=2mol / L, use 3mol / L NH under vigorous stirring 3 ·H 2 O for precipitation, the titration end point is pH 12, add polyethylene glycol 1.2g, fully stir for 20min, let stand at room temperature for 1h, and age at 60°C for 3h; stir and mix the two suspensions thoroughly, and carry out the second phase at 80°C Secondary aging, the aging time is 16h. Use vacuum filtration to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com