Samarium-doped manganese pickaxe composite oxide catalyst and preparation method and application thereof

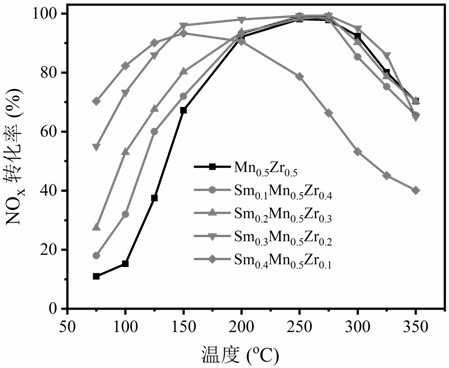

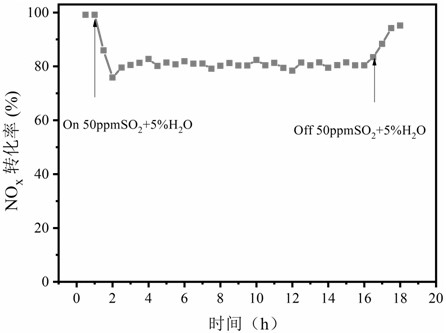

A composite oxide and catalyst technology, applied in the field of environmental protection technology and environmental catalysis, can solve problems such as no catalyst process, and achieve the effects of good medium and low temperature denitration efficiency, high efficiency, and good anti-sulfur poisoning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] mn 0.5 Zr 0.5 Preparation of Manganese-Zirconium Composite Oxide Catalyst

[0023] Step (a) Weigh an appropriate amount of zirconium nitrate, dissolve it in deionized water, prepare a 5mol / L zirconium nitrate solution, and place it for later use.

[0024] Step (b) Take 11.62ml of 50 wt% manganese nitrate solution and 10ml of 5mol / L zirconium nitrate solution prepared in step (a), stir and mix at room temperature for 30min to obtain a mixed solution;

[0025] Step (c) To the mixed solution obtained in step (b), add an appropriate amount of ammonia water (26 wt%) drop by drop while stirring, so that the pH reaches 9-10, and stir for 1 hour to obtain a suspension.

[0026] Step (d) Suction filter the suspension obtained in step (c), wash with deionized water, and dry the obtained precipitate in an oven at 120ºC for 10-15 hours, then put it into a muffle furnace and roast for 4 hours to prepare The desired samarium-doped manganese-ax composite oxide catalyst was obtained...

Embodiment 2

[0029] SM 0.1 mn 0.5 Zr 0.4 Preparation of Samarium Manganese Zirconium Composite Oxide Catalyst

[0030] Step (a) Weigh an appropriate amount of zirconium nitrate and samarium nitrate and dissolve them in deionized water to prepare a zirconium nitrate solution with a concentration of 4 mol / L and a samarium nitrate solution with a concentration of 1 mol / L, and store them for later use.

[0031] In step (b), take 11.62ml of 50 wt% manganese nitrate solution, 10ml of 4mol / L zirconium nitrate solution and 10ml of 1mol / L samarium nitrate solution prepared in step (a), stir and mix at room temperature for 30min to obtain a mixed solution;

[0032] Step (c) To the mixed solution obtained in step (b), add ammonia water (26 wt%) drop by drop while stirring to make the pH reach 9-10, stir for 1 hour to obtain a suspension.

[0033] Step (d) Suction filter the suspension obtained in step (c), wash it with deionized water, and dry the obtained precipitate in an oven at 120 ºC for 10-...

Embodiment 3

[0036] SM 0.2 mn 0.5 Zr 0.3 Preparation of Samarium Manganese Zirconium Composite Oxide Catalyst

[0037] Step (a) Weigh an appropriate amount of zirconium nitrate and samarium nitrate and dissolve them in deionized water to prepare a zirconium nitrate solution with a concentration of 3 mol / L and a samarium nitrate solution with a concentration of 2 mol / L, and store them for later use.

[0038] In step (b), take 11.62ml of 50 wt% manganese nitrate solution, 10ml of 3mol / L zirconium nitrate solution and 10ml of 2mol / L samarium nitrate solution prepared in step (a), stir and mix for 30min at room temperature to obtain a mixed solution;

[0039] Step (c) To the mixed solution obtained in step (b), add ammonia water (26 wt%) drop by drop while stirring to make the pH reach 9-10, stir for 1 hour to obtain a suspension.

[0040] Step (d) Suction filter the suspension obtained in step (c), wash with deionized water, and dry the obtained precipitate in an oven at 120ºC for 10-15 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com