Method for preparing Y zeolite catalyst used for denitration of coal fired power plant from coal ash

A technology of coal-fired power plants and molecular sieves, applied in the direction of molecular sieve catalysts, separation methods, chemical instruments and methods, etc., to achieve the effects of low drug prices, good development prospects, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] step one:

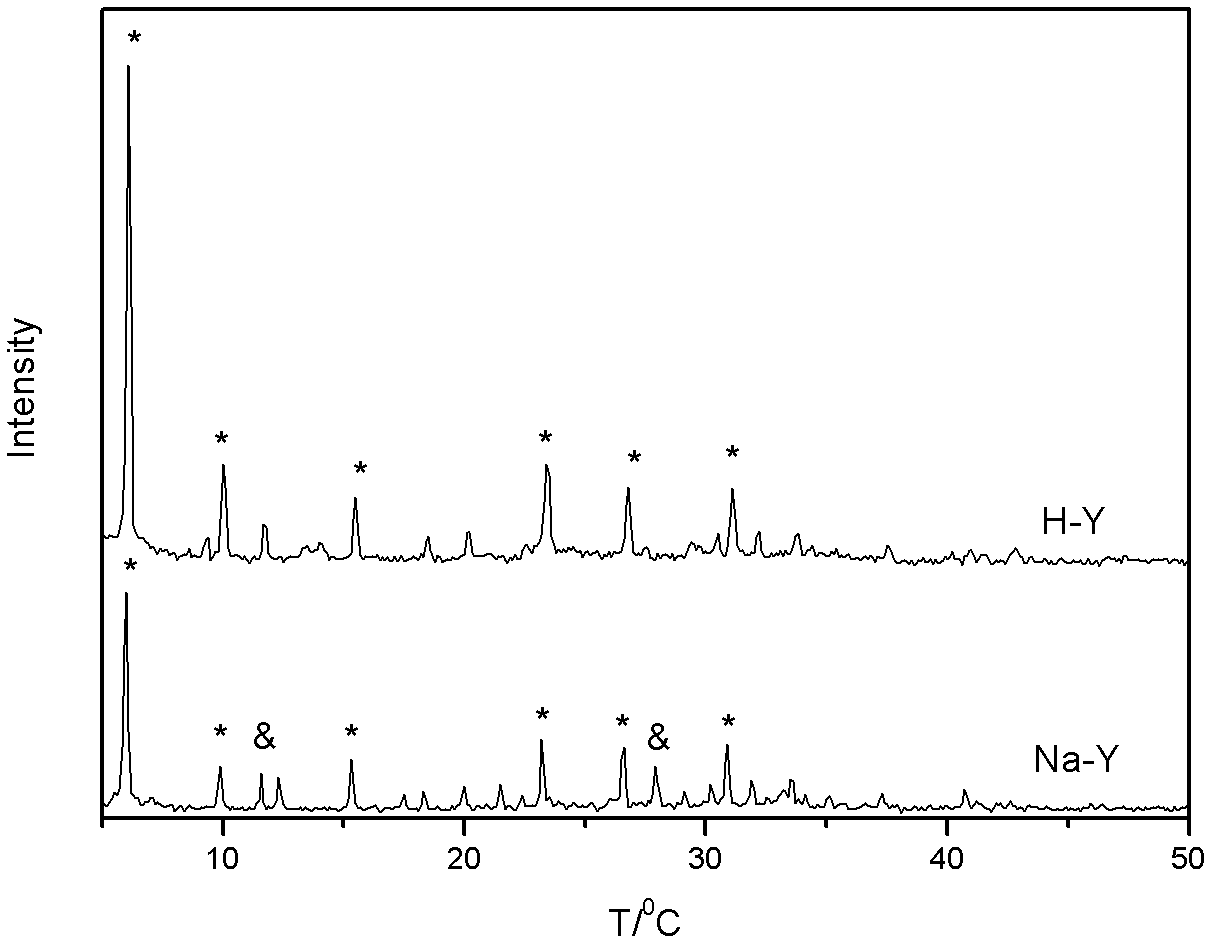

[0030] The fly ash of the power plant is calcined at 750°C for 8 hours to remove the residual carbon in the fly ash, and after cooling to room temperature, it is mixed with sodium hydroxide as an activator in a mass ratio of 1:1.2 (g fly ash / g sodium hydroxide ), melted and roasted at 600°C for 6h, cooled to room temperature, added 120ml of water, stirred at 60°C for 24h, aged in a water bath at 60°C for 24h, and put it into a static reaction kettle Crystallization, the crystallization temperature is 100°C, the crystallization time is 24h, the sample in the washing kettle is taken out until it is neutral, dried and roasted in a muffle furnace at 550°C for 6h to obtain a sodium Y molecular sieve, hereinafter referred to as NaY, the crystallinity and productive rate are shown in Table 2;

[0031] Step two:

[0032] The preparation mass fraction is 10% ammonium nitrate (NH 4 NO 3 , analytically pure) solution, weighed 2.0g of sodium-type Y molecular sieve and...

Embodiment 2

[0038] step one:

[0039] The fly ash of the power plant is calcined at 700°C for 10 hours to remove the residual carbon in the fly ash, and after cooling to room temperature, it is mixed with sodium hydroxide as an activator in a mass ratio of 1:1.2 (g fly ash / g sodium hydroxide ), melted and roasted at 620°C for 6h, cooled to room temperature, added 120ml of water, stirred at 60°C for 24h, aged in a water bath at 60°C for 24h, and put it into a static reaction kettle Crystallization, the crystallization temperature is 100°C, and the crystallization time is 24h. Take out the sample in the washing kettle until it is neutral, dry it and roast it in a muffle furnace at 550°C for 6h to obtain a sodium-type Y molecular sieve, which is hereinafter referred to as NaY-1. Crystallinity and yield are shown in Table 2;

[0040] Step two:

[0041] The preparation mass fraction is 10% ammonium nitrate (NH 4 NO 3 , analytically pure) solution, weighed 2.0g of NaY-1 and added 150ml of a...

Embodiment 3

[0045] step one:

[0046] The fly ash of the power plant is calcined at 700°C for 10 hours to remove the residual carbon in the fly ash. After cooling to room temperature, it is mixed with sodium hydroxide as an activator in a mass ratio of 1:1.4 (g fly ash / g sodium hydroxide ), melted and roasted at 620°C for 6h, cooled to room temperature, added 150ml of water, stirred at 60°C for 24h, aged in a water bath at 60°C for 24h, and put it into a static reaction kettle. Crystallization, the crystallization temperature is 100°C, and the crystallization time is 24h. Take out the sample in the washing kettle until it is neutral, dry it and roast it in a muffle furnace at 550°C for 6h to obtain a sodium-type Y molecular sieve, which is hereinafter referred to as NaY-2. Crystallinity and yield are shown in Table 2;

[0047] Step two:

[0048] The preparation mass fraction is 8% ammonium nitrate (NH 4 NO 3 , analytically pure) solution, weighed 2.0g of sodium-type Y molecular sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com