Concrete release agent and preparation method thereof

A concrete release agent and polymer technology, which is used in manufacturing tools, ceramic molding machines, etc., can solve the problems that the concrete appearance template paint cannot be quickly constructed, and the release agent cannot be obtained well, so as to reduce surface pores and reduce loss. The effect of excellent water and product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

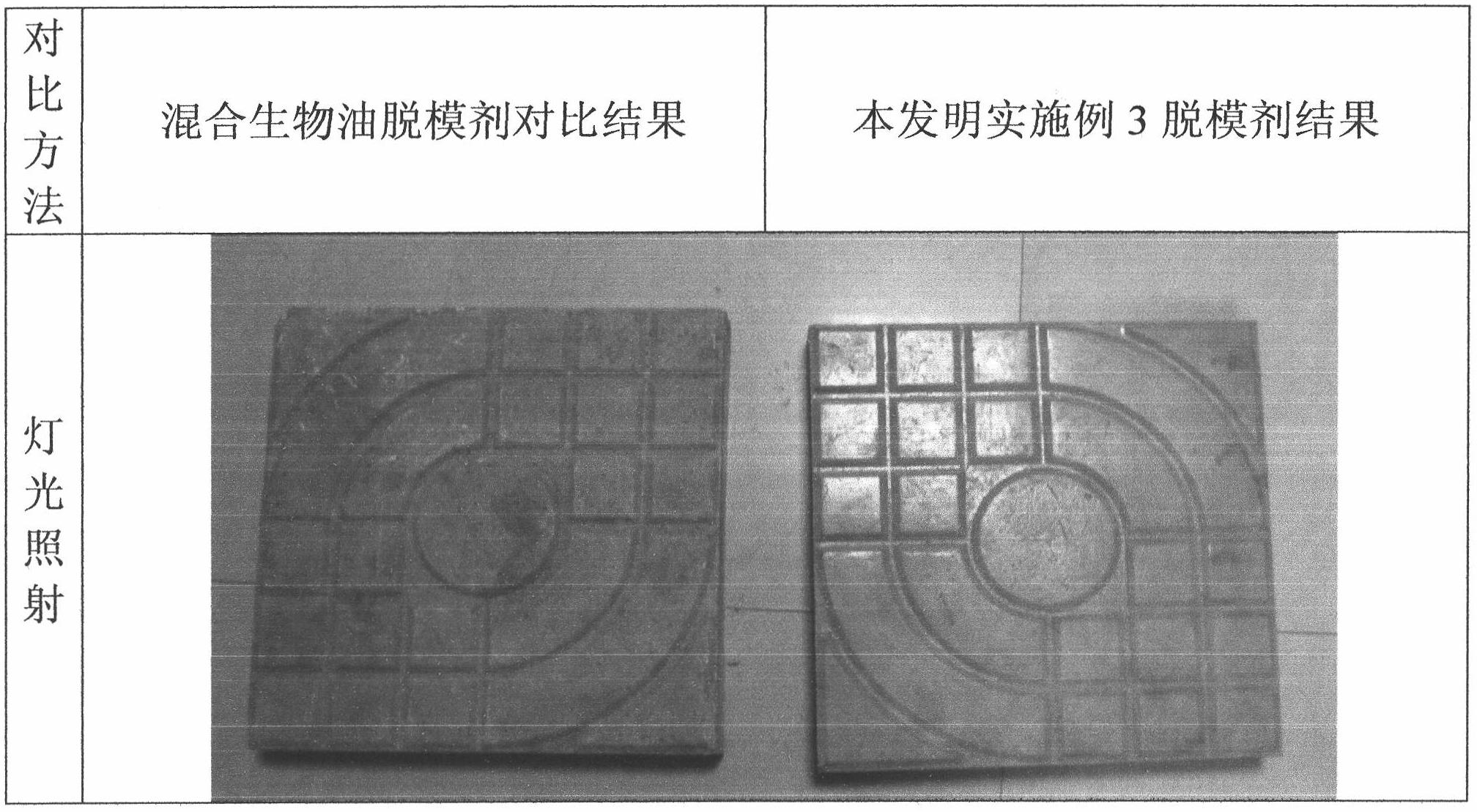

[0032] The invention provides a release agent for concrete with functions of improving surface smoothness and maintenance and a preparation method thereof. The preparation method includes the following steps: cleaning the waste high polymer, drying and pulverizing properly, adding an organic solvent and stirring to dissolve it.

[0033] Most of the release agents in the prior art are products obtained by simply emulsifying natural oil or oil-like substances as the main film-forming substance under the joint action of other auxiliary materials.

[0034] And the present invention, is to use the synthetic resin of petrochemical products, the waste material of plastic completely as film-forming material, in use, not only can guarantee stable performance, and can turn waste into wealth, reduce white pollution.

[0035] In the prior art, although some release agents use chemical products as film-forming substances, their film-forming substances are surface-active substances. As we a...

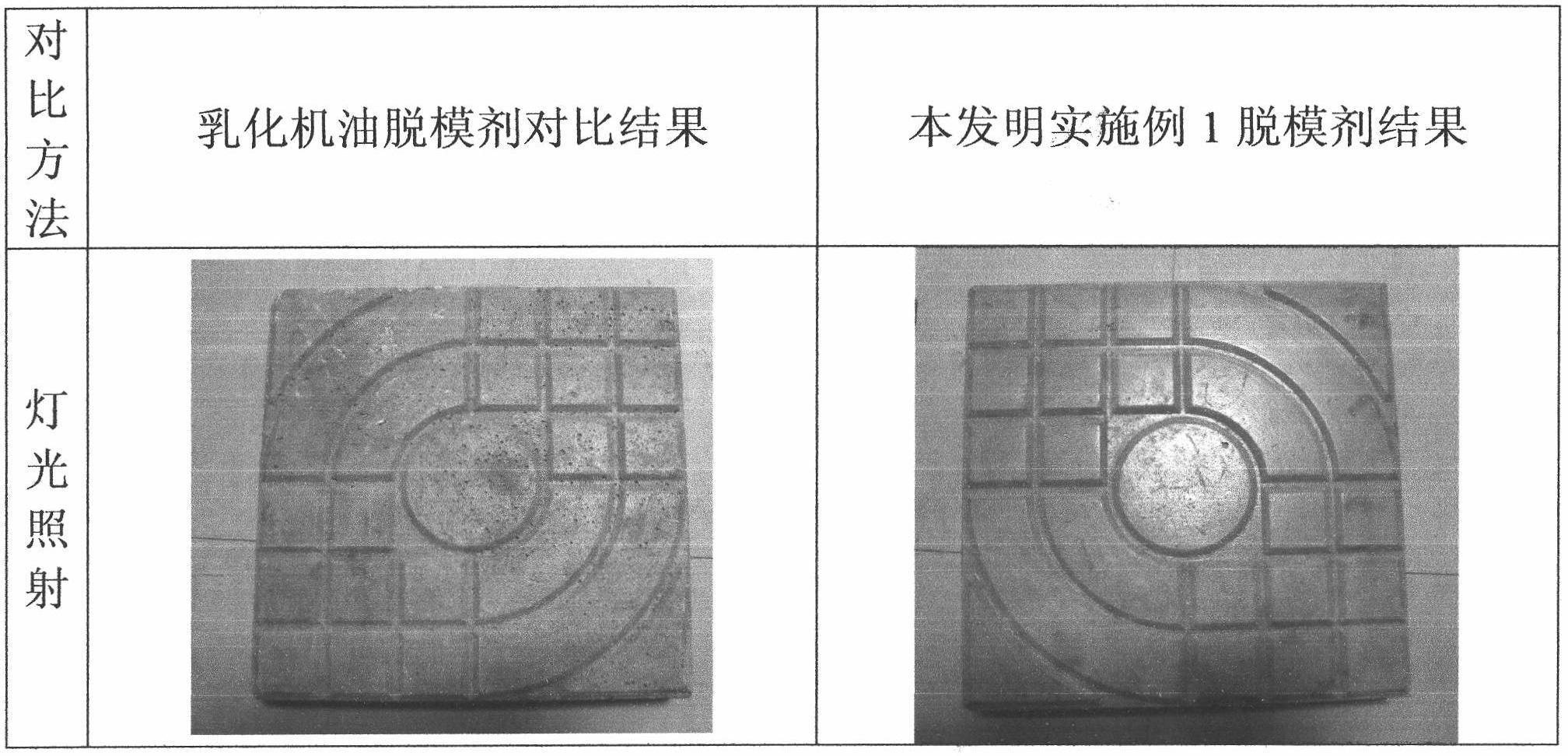

Embodiment 1

[0041] The waste high polymer is: 60 parts of polyurethane waste foam plastics;

[0042] The organic solvents are: 40 parts of dimethylformamide and 70 parts of dibutyl adipate.

[0043] The concrete release agent is prepared by the following method:

[0044] a. Clean the waste high polymer, remove the dirt that affects the film-forming property of the waste high polymer, and the dirt that affects the color of the finished concrete release agent.

[0045] b. Dry the waste high polymer to reduce the water content of the cleaned waste high polymer to the following level: it can be well dissolved in the solvent without delamination or precipitation. This step is generally to reduce the water content of the cleaned waste high polymer to: 0.1%-1%.

[0046] c. Grinding the waste high polymer into granules: Grinding the dried waste high polymer into granules with a particle diameter of 3-50 mm.

[0047] d. Add an organic solvent and stir to dissolve it to obtain the product.

[004...

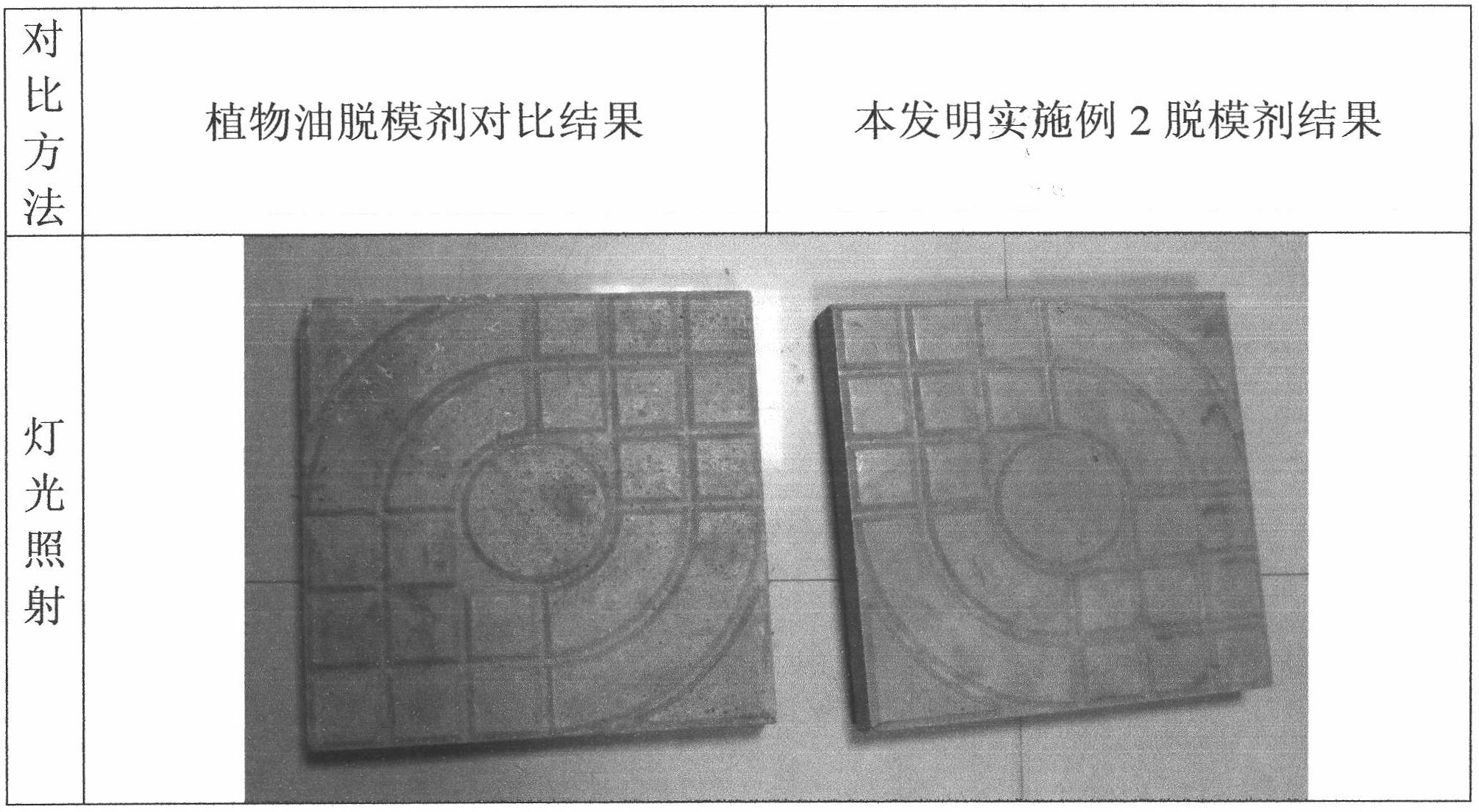

Embodiment 2

[0054] The waste high polymer is: 60 parts of clean and dry polyurethane waste foam plastics;

[0055] The organic solvents are: 35 parts of dimethyl sulfoxide and 70 parts of diethylene glycol monobutyl ether.

[0056] The concrete release agent is prepared by the following method:

[0057] a. Clean the waste high polymer, remove the dirt that affects the film-forming property of the waste high polymer, and the dirt that affects the color of the finished concrete release agent.

[0058] b. Dry the waste high polymer to reduce the water content of the cleaned waste high polymer to the following level: it can be well dissolved in the solvent without delamination or precipitation. This step is generally to reduce the water content of the cleaned waste high polymer to: 0.1%-1%.

[0059] c. Grinding the waste high polymer into granules: Grinding the dried waste high polymer into granules with a particle diameter of 3-50 mm.

[0060] d. Add an organic solvent and stir to dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com