Single-component epoxy heat-conducting adhesive

A thermally conductive adhesive, one-component technology, applied in the direction of in-line phenolic epoxy resin adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problem that the surface treatment of thermally conductive fillers is not listed in relevant patents mentioned and other issues, to achieve good storage stability, reduce usage, and meet the effects of thermally conductive packaging and bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

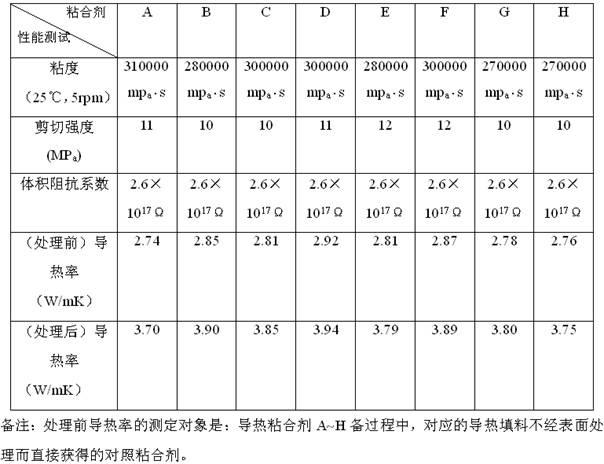

Image

Examples

Embodiment 1

[0017] Embodiment 1 Preparation of thermally conductive filler A

[0018] Raw materials are prepared according to the following weight percentages: nano-silicon carbide (thermally conductive filler) 10%, lauric acid (organic acid) 0.5% and γ-aminopropyltriethoxysilane (coupling agent) 0.5%, and the balance is acetic acid ethyl ester (solvent).

[0019] Take lauric acid and dissolve it in ethyl acetate with slight heat, add nano-silicon carbide powder to grind and disperse, add γ-aminopropyltriethoxysilane after the grinding is complete, continue to stir for a period of time until uniform, and then vacuum at 75°C In a rake-type vacuum dryer with a temperature of 0.85Mpa, the ethyl acetate is completely volatilized, the solvent is condensed and recycled for use, and the powder is collected for later use.

Embodiment 2

[0020] Example 2 Preparation of thermally conductive filler B

[0021] Raw materials are prepared according to the following weight percentages: nano-aluminum nitride (thermally conductive filler) 13%, stearic acid (organic acid) 0.8% and γ-aminopropyltriethoxysilane (coupling agent) 0.2%, the balance For methanol (solvent).

[0022] Take stearic acid and dissolve it in methanol slightly, add nano-aluminum nitride powder to grind and disperse, add γ-aminopropyltriethoxysilane after the grinding is complete, continue to stir for a period of time until uniform, and then vacuum at 70°C The temperature is 0.8Mpa in a rake-type vacuum dryer to completely volatilize the methanol, the solvent is condensed and recycled, and the powder is collected for later use.

Embodiment 3

[0023] Example 3 Preparation of thermally conductive filler C

[0024] Raw materials are prepared according to the following weight percentages: 17% of nano-alumina (thermally conductive filler), 2% of lauric acid (organic acid) and 1% of monoalkoxy pyrophosphate titanate (coupling agent), and the balance is acetone ( solvent).

[0025] Take lauric acid and dissolve it in acetone with slight heat, add nano-alumina powder for grinding and dispersing, add monoalkoxy pyrophosphate titanate after grinding, continue stirring for a period of time until uniform, and then vacuum at 75°C to 0.85Mpa In the lower rake vacuum dryer, the acetone is completely volatilized, the solvent is condensed and recycled, and the powder is collected for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com