Method of refining furfural through six-tower continuous rectification

A technology of furfural and rectification, applied in the direction of organic chemistry, can solve the problems of wasting furfural, not making full use of heat energy, polluting the surrounding environment, etc., and achieve the effects of reducing corrosion, reducing yield and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

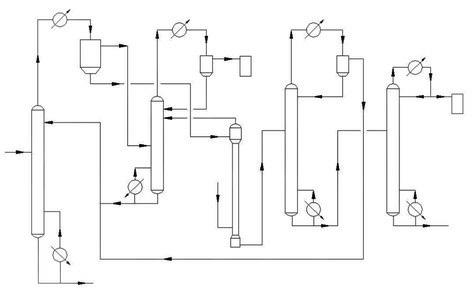

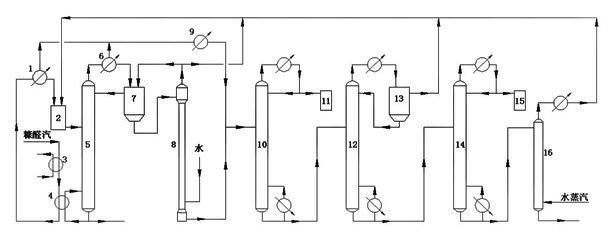

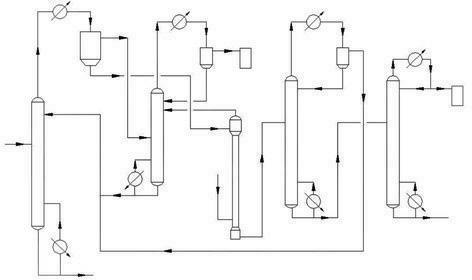

Method used

Image

Examples

Embodiment 1

[0020] The vapor pressure of furfural is 0.6MPa, the temperature is 158.6℃, its mass composition is methanol 0.1%, formic acid 1%, acetic acid 2%, methylfurfural 2.5%, furfural 8%, water 86.3%, acetone content 400mg / L, the raw material is first The 0.4MPa water vapor is generated by the steam generator as the steam source of the stripping tower; the aldehyde vapor is then heat-exchanged with the reboiler of the initial distillation tower, and the temperature drops to 90°C, and then fed from the middle and upper part of the initial distillation tower. Operated under normal pressure, the temperature at the top of the tower is 97.4°C. The furfural water azeotrope produced at the top of the initial distillation tower is refluxed to the initial distillation tower through the upper water phase condensed in the phase separation tank of the initial distillation tower, and the initial distillation tower is separated. The furfural phase in the middle and lower layers of the tank is sent ...

Embodiment 2

[0022] The furfural vapor pressure is 0.7MPa, the temperature is 164.7°C, and its mass composition is methanol 0.1%, formic acid 1.4%, acetic acid 2.5%, methylfurfural 3%, furfural 6.8%, water 86.1%, acetone content 385mg / L, other processes Condition is identical with embodiment 1, and the product that refining tower tower top obtains consists of: acetic acid content 144mg / L, formic acid content 108 mg / L, methanol content 28mg / L, water content 0.03%, methyl furfural content is 0.7%, furfural The content is 99.2%, and the yield of furfural is 96.1%.

Embodiment 3

[0024] The vapor pressure of furfural is 0.6MPa, the temperature is 158°C, and its mass composition is 0.6% formic acid, 1.5% acetic acid, 2% methylfurfural, 7.3% furfural, 88.4% water, 412mg / L acetone, and 871mg / L methanol. Other process conditions are the same as in Example 1, and the product obtained at the top of the refining tower consists of: acetic acid content 102 mg / L, formic acid content 135 mg / L, methanol content 10 mg / L, water content 0.042%, and methylfurfural content 0.3 %, the furfural content is 99.6%, and the furfural yield is 97.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com