Obligate halophile for processing high-salt oily waste liquor in petroleum industry

A technology of halophilic bacillus and waste liquid, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, bacteria, etc., and can solve the problems of reducing microbial activity and metabolism, difficulty in treating common microorganisms, and incomplete treatment, etc. , to achieve the effect of strong environmental adaptability, good industrial application prospects, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

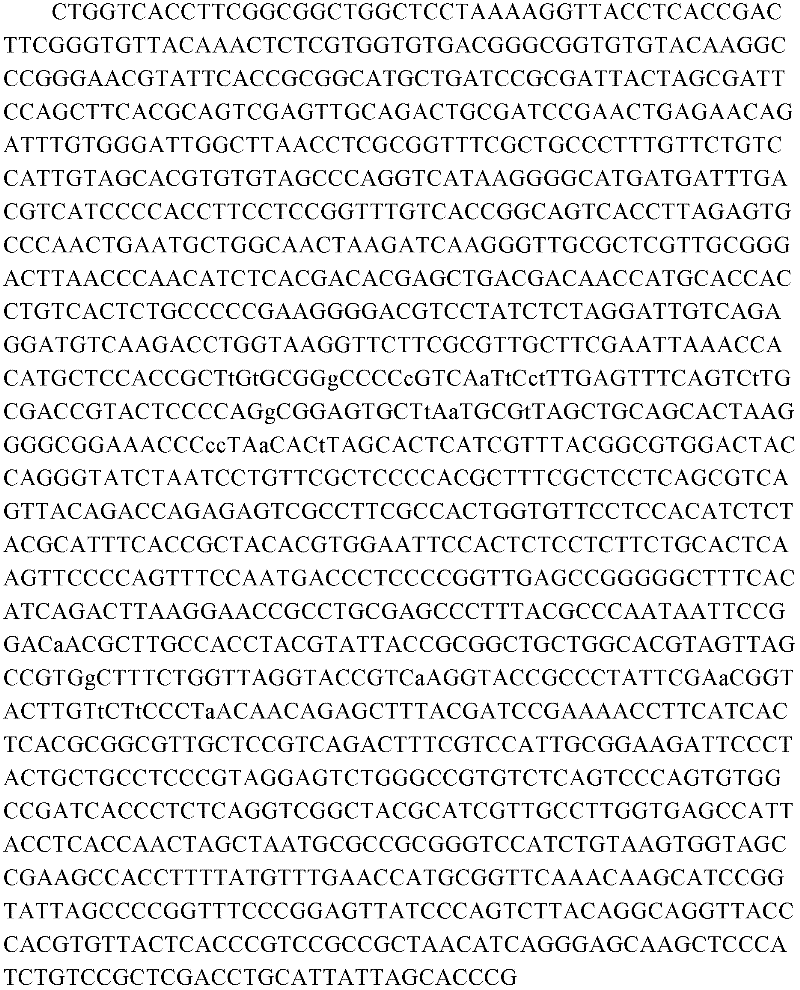

Image

Examples

Embodiment 1

[0020] Example 1, Screening and cultivation of Bacillus subtilis subsp.spizizenii Y-B CGMCCNo.4194 and its treatment effect on different oily waste liquids

[0021] Screening and cultivation of Bacillus subtilis subsp.spizizenii Y-B CGMCC No.4194:

[0022] Weigh 10g of oil field drilling waste mud, put it into a triangular flask filled with 90ml of sterile normal saline, and vibrate at a constant temperature for 18-24 hours at a temperature of 25-30°C, absorb 5ml of bacterial suspension with a sterile pipette tip and add it to the flask. In 45ml of halophilic bacteria culture medium, the mass percentage of each component of the halophilic bacteria culture medium is: acid hydrolyzed casein 0.5%, yeast extract 1.0%, bacto-peptone 0.5%, trisodium citrate 0.3%, KCl 0.3%, MgSO 4 7H 2 O 1.8%, CaCl 2 0.02%, NaCl 5%, FeSO 4 7H 2 O solution 0.0001%, the rest is distilled water. Cultivate at a temperature of 25-30°C for 2-3 days to obtain a halophilic strain.

[0023] Take 5ml of ...

Embodiment 2

[0035] Example 2: Degradation ability of halophilic bacillus strain Y-B CGMCC No.4194 to drilling waste mud under optimized degradation conditions:

[0036] The pH of the waste drilling mud is around 9. According to the optimized degradation conditions of Bacillus subtilis subsp.spizizeniiY-B CGMCC No.4194, the waste drilling mud with an oil concentration of about 600mg / L is added with a volume percentage of 8% halophilic Bacillus subtilis subsp.spizizenii Y-B CGMCC No.4194, then add (NH 2 ) 2 CO nitrogen source and K 2 HPO 4 3H 2 O phosphorus source, keep N:P 1:1~3:1, shake treatment at 25~30°C for 7 days, test the change of oil content in the solution before and after treatment, and do not add other chemical treatment agents during the test. Tests show that after optimization of the degradation conditions, the degradation ability of the halophilic Bacillus subtilis subsp. spizizenii Y-B CGMCC No.4194 to waste mud increases by 23%, from 51.21% to 70%-80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com