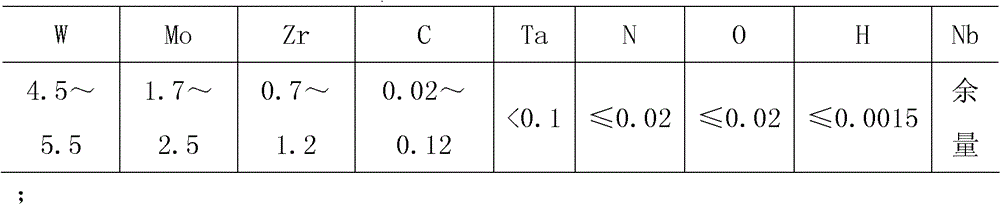

High-temperature and high-specific strength niobium alloy and preparation method thereof

A high specific strength, niobium alloy technology, applied in the field of niobium-based superalloy and its ingots, can solve the problems of insufficiency and high cost, achieve good economic value and social value, and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 5.1% tungsten and 2.1% molybdenum powder to 93kg metallurgical grade niobium powder, and add 0.2% rare earth element yttrium at the same time. It is required that the excess carbon content of niobium powder is controlled at 1000ppm, and the material is mixed in a V-shaped mixer for 4- 10 hours; the alloy powder is formed by a 500-ton hydraulic steel mold, and then sintered at a high temperature in a vacuum: 2h to 1350°C for 2h, 2h to 1700°C for 2h, 2h to 1850°C for 10-20h, power off for cooling, Make the vacuum greater than 2×10 -2 Pa. The alloy strip and the zirconium plate are assembled according to the weight ratio of 100:1-1.5 to prepare the smelting electrode. Vacuum electron beam furnace is used for two smelting, the melting power is 200kW-500kW, and the smelting speed is 70-100kg / h. The surface of the ingot is polished to eliminate surface defects.

Embodiment 2

[0023] Add 5.1% tungsten, 2.1% molybdenum powder, and 0.2% rare earth element yttrium to 93kg of metallurgical grade niobium powder, and mix in a V-shaped mixer for 4-10 hours; carry out isostatic pressing on the alloy powder Forming, the diameter of the formed billet is Φ80mm, and then sintered by vacuum vertical melting: 70-100kW heat preservation for 1-2 hours, 150-250kW heat preservation for 2-3 hours, power off for cooling. Alloy rods and zirconium plates are assembled according to the weight ratio of 100:1-1.5 to prepare melting electrodes. The first melting uses a vacuum electron beam furnace with a melting power of 200kW-500kW and a melting speed of 70-100kg / h, and the second uses a vacuum For consumable arc melting, the melting power is 300kW-560kW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com