Polyester and production method thereof

A technology of polyester and polycondensation reaction, which is applied in the field of hydrolysis-resistant polyester and its production, and can solve problems such as impact and unfavorable performance of polyester products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

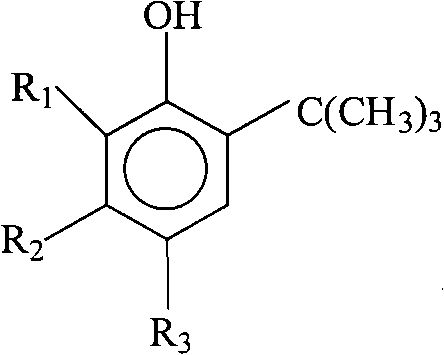

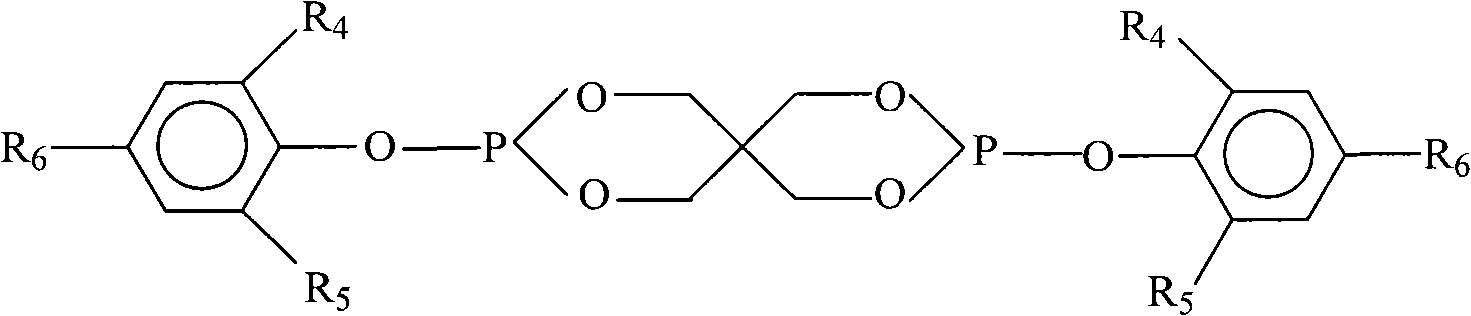

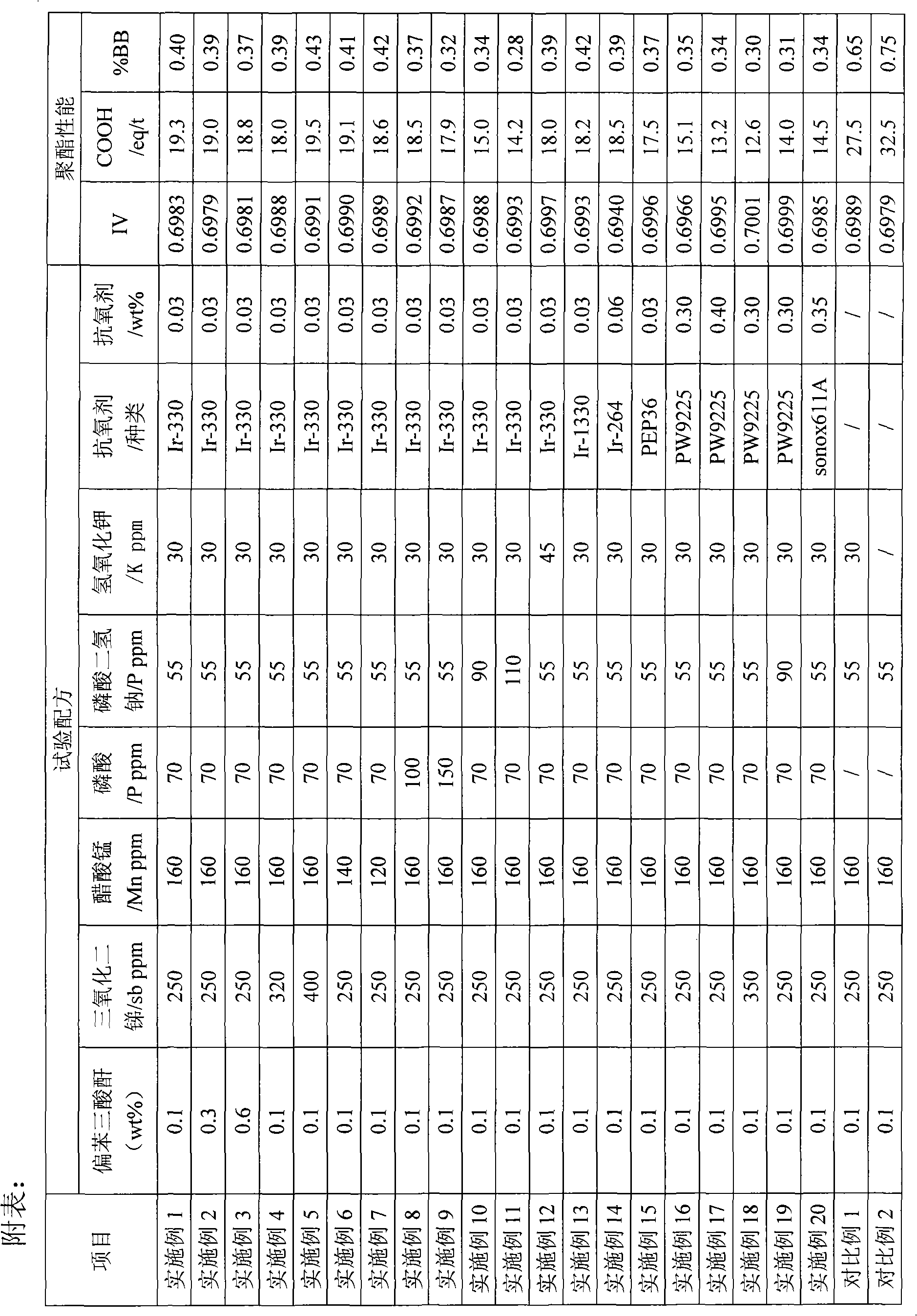

[0047] A hydrolysis-resistant polyester synthesized by transesterification. A small molecular polymer is obtained by transesterification reaction of aromatic dicarboxylic acid ester, aliphatic dihydric alcohol and benzoic acid compound with three substituent groups on the benzene ring. In this process, inorganic antimony compound and organic acid manganese compound are added as Catalyst for the transesterification reaction; polycondensation reaction of the obtained small molecule polymer to obtain hydrolysis-resistant polyester, adding stabilizer phosphorus compound, inorganic phosphate, antioxidant, trisubstituted benzoic acid, potassium hydroxide respectively in the polycondensation reaction.

[0048] Polyester is polyethylene terephthalate obtained by transesterifying dimethyl terephthalate with ethylene glycol.

[0049] The antimony compound used is antimony trioxide, the manganese compound is manganese acetate, the stabilizer phosphorus compound is phosphoric acid, the in...

Embodiment 2

[0071] Relative to polyester weight, where,

[0072] Antimony element content in antimony trioxide: 250ppm;

[0073] Manganese element content in manganese acetate: 160ppm;

[0074] Addition of hindered phenol antioxidant Ir-300: 0.03wt%;

[0075] Phosphorus element content in phosphoric acid: 70ppm;

[0076] Phosphorus element content in sodium dihydrogen phosphate: 55ppm;

[0077] Potassium element content in potassium hydroxide: 30ppm;

[0078] Addition of trimellitic anhydride (TMA): 0.3 wt%.

[0079] The rest are the same as in Example 1, the COOH content of the polyester before hydrolysis treatment is 19.0eq / t, and its BB% after hydrolysis treatment is 0.39.

Embodiment 3

[0081] Relative to polyester weight, where,

[0082] Antimony element content in antimony trioxide: 250ppm;

[0083] Manganese element content in manganese acetate: 160ppm;

[0084] Addition of hindered phenol antioxidant Ir-300: 0.03wt%;

[0085] Phosphorus element content in phosphoric acid: 70ppm;

[0086] Phosphorus element content in sodium dihydrogen phosphate: 55ppm;

[0087] Potassium element content in potassium hydroxide: 30ppm;

[0088] Addition of trimellitic anhydride (TMA): 0.6 wt%.

[0089] The rest are the same as in Example 1, the COOH content of the polyester before hydrolysis treatment is 18.8eq / t, and its BB% after hydrolysis treatment is 0.37.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com