Self-flowing para-phenylene terephthalamide and preparation method thereof

A para-aramid fiber, self-flowing technology, applied in the direction of single-component polyamide rayon, can solve the problems of inability to improve the solubility of aramid fiber, decline in mechanical properties, deterioration in mechanical properties, etc., and achieve excellent self-flowing performance , the effect of broadening the spinning conditions and smoothing the polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

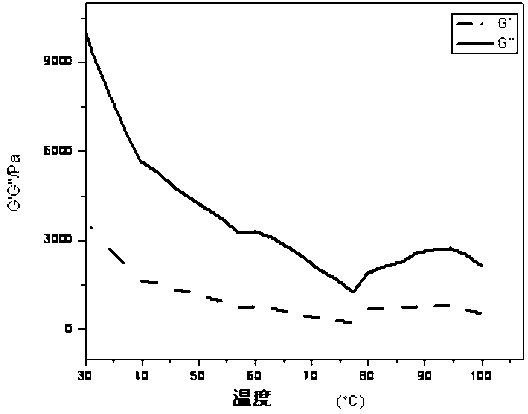

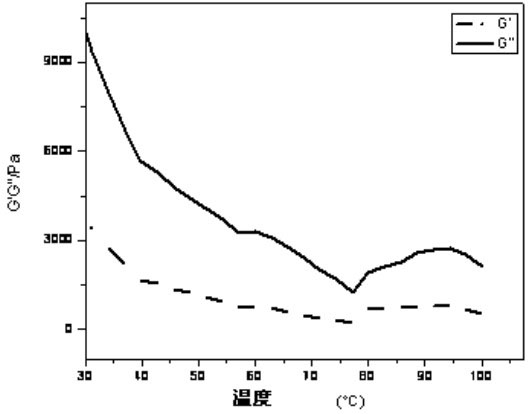

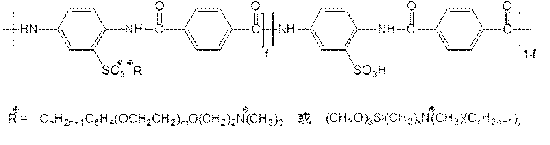

[0025] Weigh 5.0g of 2,5-diaminobenzenesulfonic acid (2,5-DABSA) with a purity greater than 97% and 20ml of dimethylacetamide (DMAC) into a 250ml four-neck flask, then add to dissolve 2.35 g of anhydrous LiCl in 80 ml of DMAC, then stirred at 100 °C until homogeneous. Then add 5.4g terephthaloyl chloride (TPC) dissolved in 30 ml DMAC to the constant pressure funnel, then lower the reaction temperature to 0°C, and make TPC under nitrogen flow and rapid stirring within 3-5 minutes Add it dropwise to a four-neck flask. When the exotherm ceased, the ice bath was removed and stirred at room temperature for 24 hours. Take by weighing 1.11g NaOH again and add in the solution, stir 3 hours, then add the 30g Jimine quaternary ammonium salt NPEQ (C 9 h 19 C 6 h 4 (OCH 2 CH 2 ) 10 O(CH 2 ) 2 N + (CH 3 ) 3 Cl - ), stirred rapidly for 6 hours, poured the final liquid into a dialysis bag, and dialyzed in the presence of circulating water, then placed the sample in the dialysis...

Embodiment 2

[0027] Weigh 5.0g of 2,5-diaminobenzenesulfonic acid (2,5-DABSA) with a purity greater than 97% and 20ml of N-methylpyrrolidone at room temperature and pour them into a 250ml four-neck flask, then add and dissolve in 4.00 g of anhydrous CaCl in 70 ml of N-methylpyrrolidone 2 , and then stirred at 90°C until homogeneous. Then add 5.4g terephthaloyl chloride (TPC) dissolved in 30ml N-methylpyrrolidone to the constant pressure funnel, then lower the reaction temperature to 2°C, and make TPC under nitrogen flow and rapid stirring within 5-6 minutes Added dropwise to a four-neck flask under the condition of When the exotherm ceased, the ice bath was removed and stirred at room temperature for 24 hours. Then weigh 1.11g NaOH and add it to the solution, stir for 3 hours, then add 20g C dissolved in 200ml distilled water to the four-necked flask. 6 h 13 C 6 h 4 (OCH 2 CH 2 ) 8 O(CH 2 ) 2 N + (CH3 ) 3 Cl - , stirred rapidly for 7 hours, poured the final liquid into a dial...

Embodiment 3

[0029] Weigh 10.0g of 2,5-diaminobenzenesulfonic acid (2,5-DABSA) with a purity greater than 97% and 10ml of N-methylpyrrolidone at room temperature and pour them into a 250ml four-neck flask, then add and dissolve in 80ml of N-methylpyrrolidone in 5g of anhydrous LiCl, then stirred at 80°C until homogeneous. Then add 11g of terephthaloyl chloride (TPC) dissolved in 30 ml of N-methylpyrrolidone to the constant pressure funnel, then lower the reaction temperature, and make TPC under nitrogen flow and rapid stirring within 3-5 minutes Add it dropwise to a four-neck flask. When the exotherm ceased, the ice bath was removed and stirred at room temperature for 24 hours. Then weigh 3.11g KOH and add it to the solution, stir for 3 hours, then add 21g (CH) dissolved in 200ml distilled water to the four-necked flask 3 O) 3 Si(CH 2 ) 5 N + (CH 3 )(C 10 h 21 )Cl - , stirred rapidly for 5 hours, poured the final liquid into a dialysis bag, dialyzed in the presence of circulating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com