Ultraviolet-assisted surface modification method and product with surface formed thereby

A UV light modification technology, applied to the surface of materials, UV assisted polymer surface modification field, can solve side reactions, reduce surface modification efficiency, unfavorable rapid production and cost saving, quinone group photosensitivity Weakness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Synthesis of molecule X-S-L

[0112] Synthesis of N-[3-(xanthone-2-carboxamido)propyl]-carbamic acid tert-butyl ester (Compound 1)

[0113]

[0114] Dissolve 2-XTC (13.2g, 55mmol) in DMF (120ml) and stir to dissolve in a water bath at 40°C. CDI (9.25g, 57mmol) was added to the solution at once, and the reaction was stirred for 4 hours and 40 minutes. The reaction system was transferred out and stirred in a water bath at 20°C for 10 minutes to cool. Dissolve monosubstituted tert-butoxycarbonyl-1,3-propanediamine (11.09g, 67mmol) in TEA / DMF (20ml, 10%v / v) solution, mix well, and add to xanthone at one time- In the reaction system of 2-formic acid and CDI, TEA (13ml) was then added, stirred and heated to 40°C, and reacted for 11 hours. The reaction system was cooled to 0°C, deionized water (700ml) was added for precipitation, suction filtration, and the obtained solid was dried at 40°C under vacuum conditions of about -0.09MPa. The yield was 41.47% (based on 2-XTC).

[0115]...

Embodiment 2

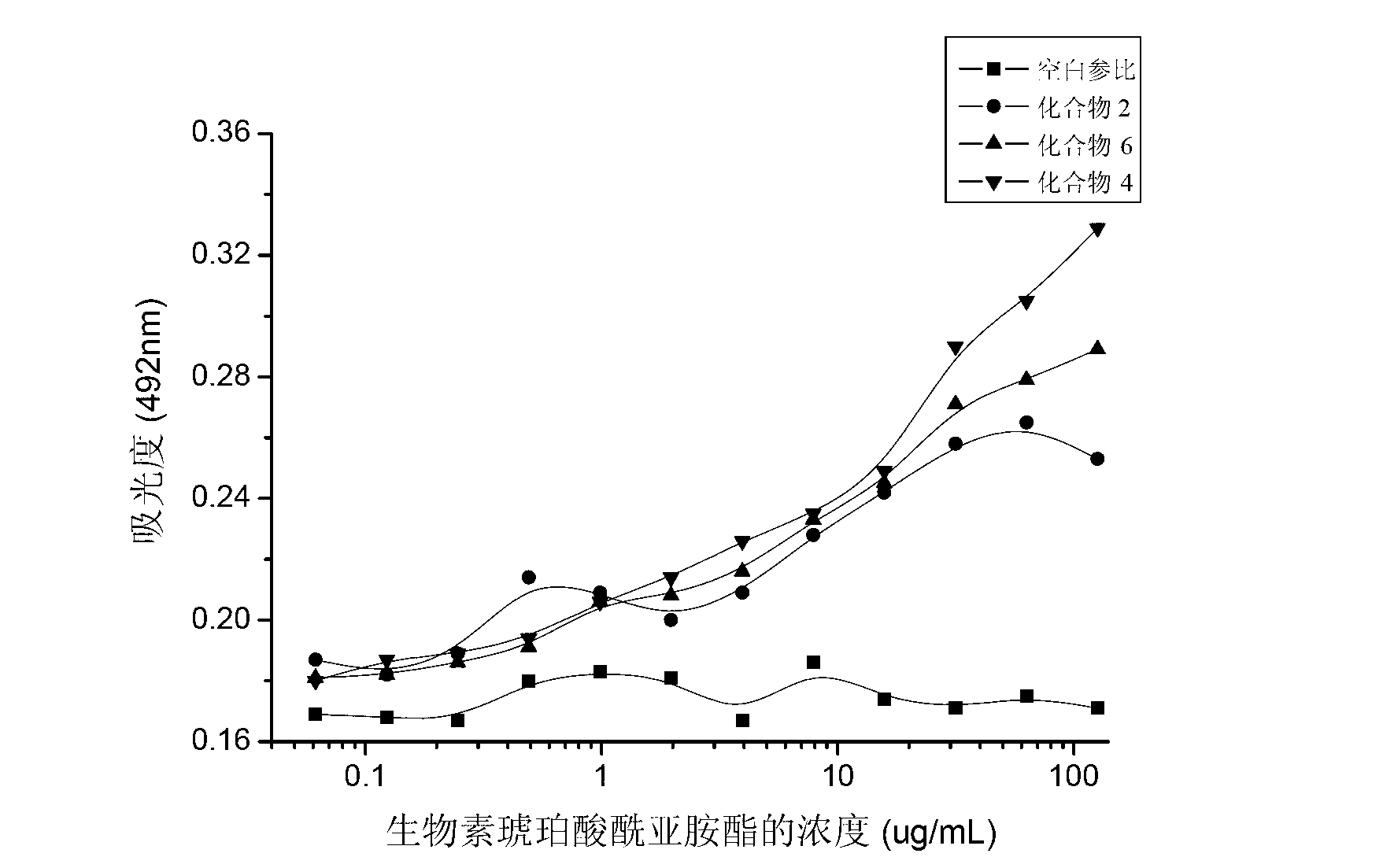

[0174] Dissolve compound 2, compound 4, compound 6, and compound 7 in pure water (conductivity = 0.8 μs / cm) to prepare a 0.05 mM solution. Dissolve 2-XTC and BP in absolute ethanol to prepare solutions with concentrations of 0.064mM and 0.053mM, respectively. Measure the ultraviolet spectrum in the wavelength range of 190-400nm. Table 1 shows the characteristic absorption wavelength of the six compounds (λ max ) And molar absorption coefficient (ε).

[0175] Table 1 UV absorption of six compounds

[0176]

Embodiment 3

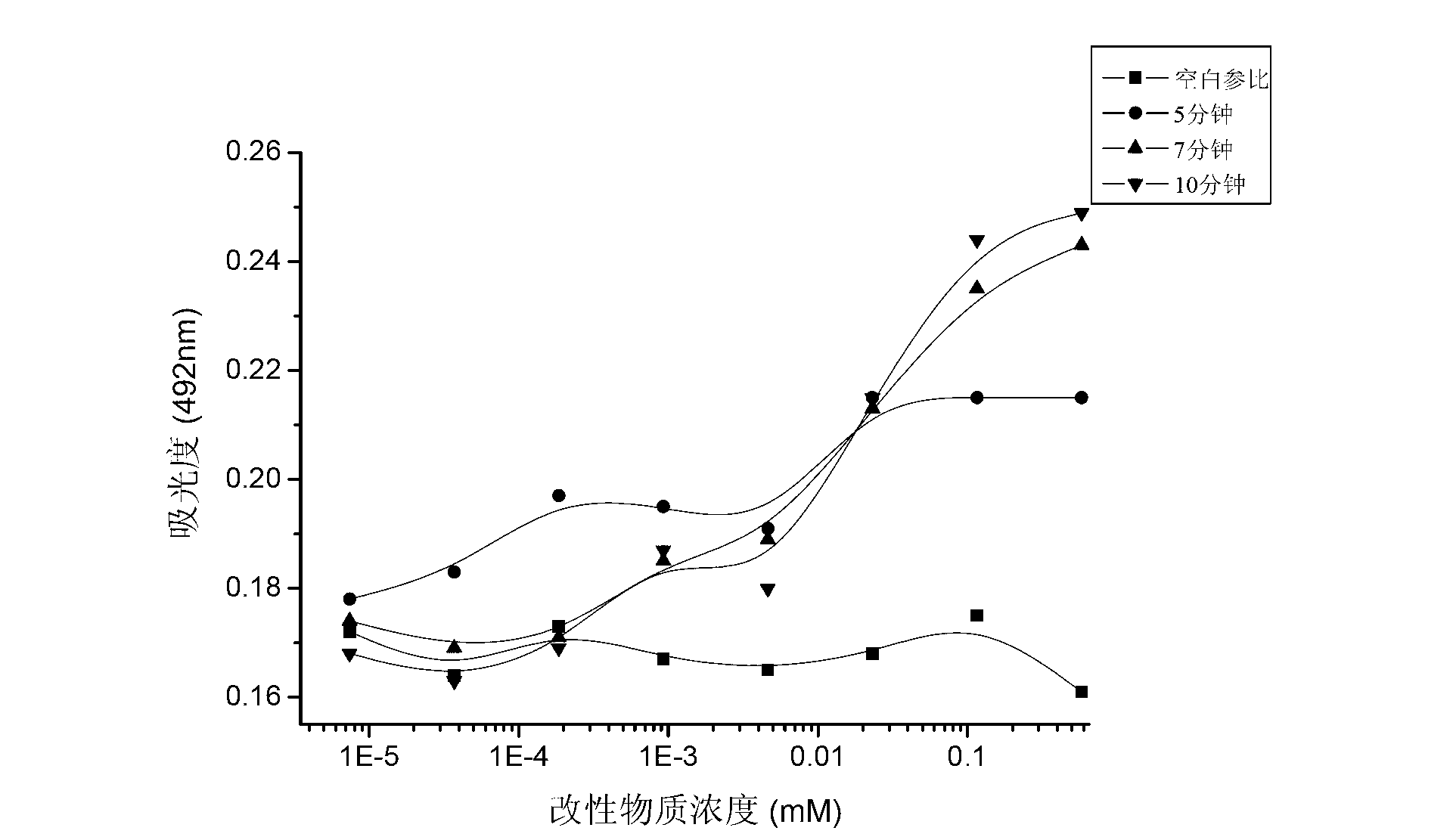

[0178] Compound 6 was dissolved in distilled water to prepare a solution with an initial concentration of 0.58 mM. Based on the above concentration, a 5-fold dilution was made to prepare a series of modified solutions. Before use, the solution of each concentration is ventilated with nitrogen for 10 minutes to remove oxygen. Take the unmodified polystyrene (PS) 96-well microtiter plate, wash the surface of the well with absolute ethanol and deionized water three times, bake at 50°C for 45 minutes, and dry for use. The modified solution prepared above was added to each well of the microtiter plate at 100μL / well, and the microtiter plate was placed under a 1000W high-pressure mercury lamp for illumination with a light intensity of 3.55mW / cm 2 (Λ=254nm), the illumination time is 5 minutes, 7 minutes and 10 minutes respectively. After the light is over, pour off the modified solution, rinse with deionized water three times, and then bake at 50°C for 45 minutes. After drying, store ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com