Preparation method of aqueous emulsion type neoprene antioxidant system product

A chloroprene rubber and antioxidant technology, applied in the field of water emulsion type chloroprene rubber antioxidant system products, can solve the problems of low anti-aging efficiency of BHT, unsatisfactory anti-aging performance, adverse environmental effects, etc. Commercially traded, excellent anti-aging properties, less volatile and migration-loss effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

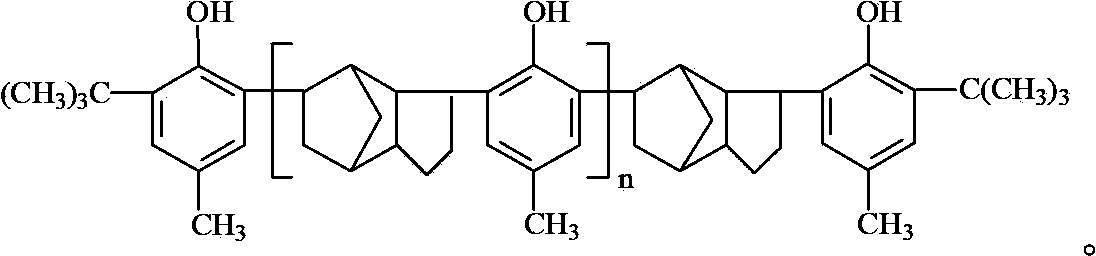

[0043] At room temperature, weigh 10kg of antioxidant Wingstay-L, 0.05kg of phenothiazine, and 0.5kg of hydroxylamine compound, stir and mix well; use a STJ100 flat jet mill to make a fine powder functional antioxidant with an average particle size of 10 μm; weigh Take 10kg of fine powder functional antioxidant, 0.025kg of surfactant, 0.05kg of dispersant, 0.005kg of wetting agent, and 10kg of deionized water into a WMB10R pin-type sand mill to make a suspension-type water with an average particle size of 1 μm. Emulsion, that is, the 1# antiaging agent of the present invention.

Embodiment 2

[0045] At room temperature, weigh 10kg of antioxidant Wingstay-L, 0.3kg of phenothiazine, and 0.6kg of hydroxylamine compound, stir and mix well; use a STJ100 flat jet mill to make a fine powder functional antioxidant with an average particle size of 50 μm; weigh Take 10kg of fine powder functional antioxidant, 0.03kg of surfactant, 0.08kg of dispersant, 0.008kg of wetting agent, and 10kg of deionized water into a WMB10R pin-type sand mill to make a suspension-type water with an average particle size of 2 μm. Emulsion, that is, the 2# antiaging agent of the present invention.

Embodiment 3

[0047] At room temperature, weigh 10kg of antioxidant Wingstay-L, 0.2kg of phenothiazine, and 0.1kg of hydroxylamine compound, stir and mix well; use a STJ100 flat jet mill to make a fine powder functional antioxidant with an average particle size of 100 μm; weigh Take 10kg of fine powder functional antioxidant, 0.05kg of surfactant, 0.1kg of dispersant, 0.01kg of wetting agent, and 10kg of deionized water into a WMB10R pin-type sand mill to make a suspension-type water with an average particle size of 3 μm. Emulsion, that is, the 3# antiaging agent of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com