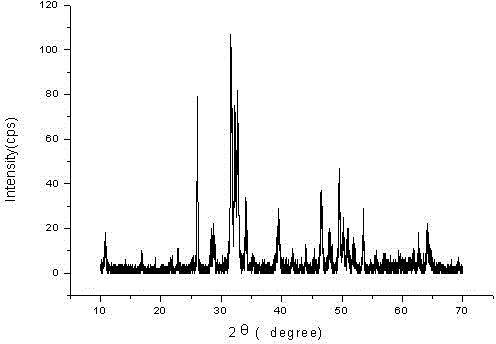

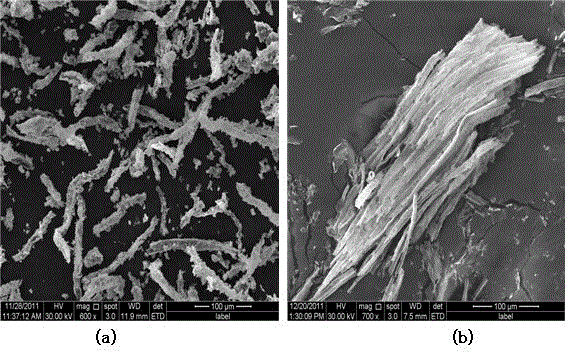

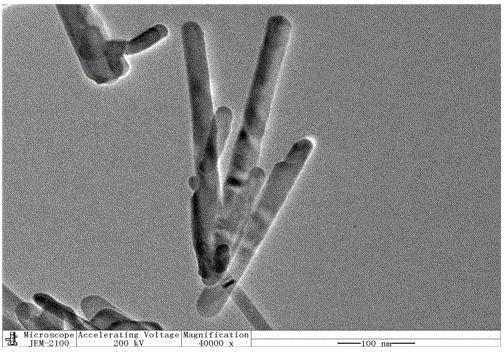

Hydroxyapatite mono-crystal nano-rod and preparation method thereof

A hydroxyapatite, single crystal nanotechnology, applied in the field of material chemistry, can solve the problems of inability to form a shape, small specific surface area, irregular arrangement of hydroxyapatite single crystal particles, etc., and achieves low production cost and large ratio. Surface area, good remineralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: A method for preparing hydroxyapatite single crystal nanorods, the specific operations are as follows:

[0038] (1) The plant template cotton was soaked in hydrochloric acid with a mass percentage concentration of 5% for 10 hours, washed with ultrapure water until neutral, and dried in an oven at 60°C for later use;

[0039] (2) Dissolve diammonium hydrogen phosphate in deionized water, stir to make it completely dissolve to obtain a homogeneous transparent solution, the concentration of hydrogen phosphate ion is 0.01mol / L, add dry cotton in the proportion of 0.5g / L as plant template;

[0040] (3) Add calcium carbonate dropwise to the above-mentioned phosphate aqueous solution at a speed of 1ml / min, continue to stir for 10min, and ultrasonicate for 5 minutes; the molar ratio of Ca:P is 1.67, and the pH value of the solution is 10 (use hydrogen Sodium to adjust the pH value), the stirring speed is 200rpm;

[0041] (4) Transfer the solution in step (3) into...

Embodiment 2

[0045] Example 2: A method for preparing hydroxyapatite single crystal nanorods, the specific operations are as follows:

[0046] (1) Plant template loofah pulp is soaked in hydrochloric acid with a mass fraction of 2% for 20 hours, washed with ultrapure water until neutral, and dried in an oven at 60°C for later use;

[0047] (2) Dissolve sodium phosphate in deionized water, stir to make it completely dissolve to obtain a homogeneous transparent solution, the concentration of phosphate ions is 0.1mol / L, and add dry loofah pulp into it at a ratio of 5g / L as a plant template;

[0048] (3) Add calcium carbonate dropwise to the above-mentioned phosphate aqueous solution while stirring at a speed of 5ml / min, continue to stir for 30min, and ultrasonicate for 8 minutes; wherein the molar ratio of Ca:P is 1.67, and the pH value of the solution is 8 (use hydrogen Potassium to adjust the pH value), the stirring speed is 500rpm;

[0049] (4) Transfer the solution in step (3) into a h...

Embodiment 3

[0052] Example 3: A method for preparing hydroxyapatite single crystal nanorods, the specific operations are as follows:

[0053] (1) Plant template leaves are soaked in hydrochloric acid with a mass fraction of 8% for 16 hours, washed with ultrapure water until neutral, and dried in an oven at 60°C for later use;

[0054] (2) Dissolve potassium phosphate in deionized water, stir to completely dissolve to obtain a homogeneous transparent solution, the concentration of phosphate ions is 0.05mol / L, and add dried leaves to it at a ratio of 1g / L as a plant template;

[0055] (3) Add calcium carbonate dropwise to the above phosphate aqueous solution at a speed of 2ml / min, continue to stir for 45min, and ultrasonicate for 7 minutes; the molar ratio of Ca:P is 1.67, and the pH value of the solution is 9 (adjusted with ammonia water) pH value), the stirring speed is 600rpm;

[0056] (4) Transfer the solution of step (3) into a hydrothermal synthesis reaction kettle, and after const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com