Method of using coal gangue to prepare fracturing propping agent

A technology for fracturing proppant and coal gangue, which can be used in earth-moving drilling, fluid production, wellbore/well components, etc., and can solve the problems of poor mechanical properties and high brittleness of proppant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

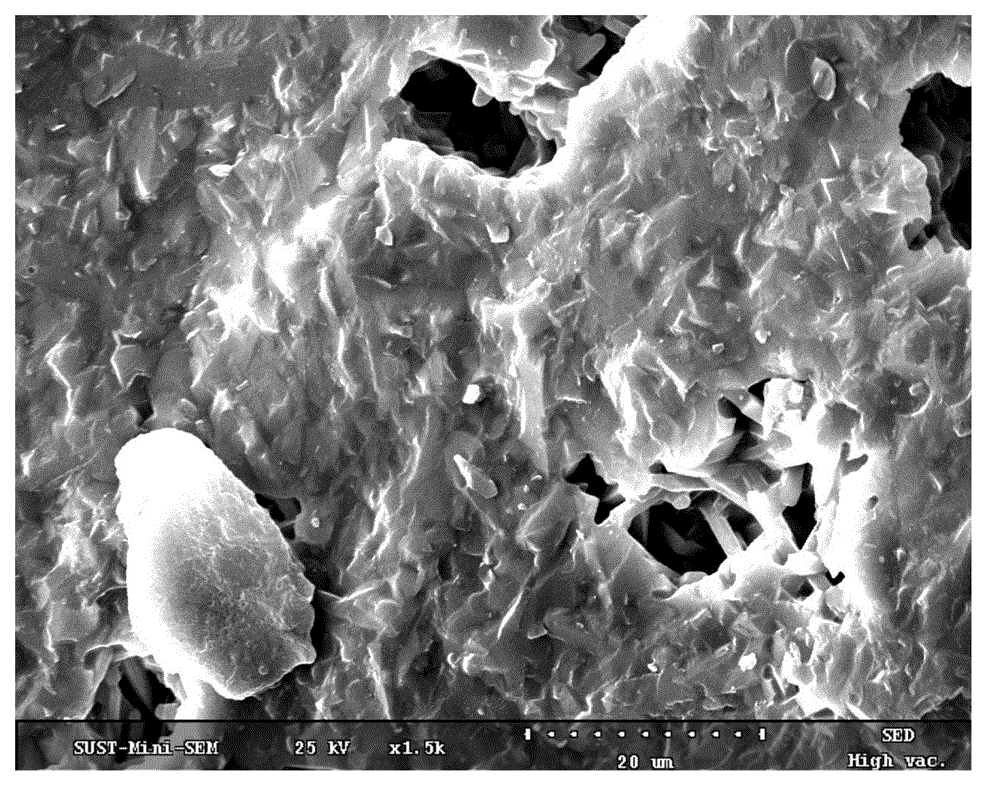

Image

Examples

Embodiment 1

[0027] 1) Put coal gangue and alumina powder into a ball mill for dry grinding, use alumina ball stone as the grinding medium, control the mass ratio of balls and raw materials to 2:1, ball mill for 0.5h to 2h respectively, and then pass through 120 Mesh sieve;

[0028] 2) According to mass percentage, mix 40% sieved coal gangue, 45% alumina powder, 5% barium carbonate and 10% alumina chopped fiber to obtain a mixture, put the mixture into a ball mill and then add Mix the gum solution with a mass concentration of 10%, use alumina ball stone as the grinding medium, control the mass ratio of the grinding ball, the mixture and the gum solution to 2:1:0.3, grind for 0.5h to 3h to form a mixed slurry, and the slurry is over 300 Mesh sieve;

[0029] Among them, the alumina powder is α-alumina for industrial use, that is, corundum powder, its corundum content is >98%, and the particle diameter of the powder is <10μm; The obtained slag-free unidirectionally extended fibers have a di...

Embodiment 2

[0033] 1) Put coal gangue and alumina powder into a ball mill for dry grinding, use alumina ball stone as the grinding medium, control the mass ratio of balls and raw materials to 2.5:1, ball mill for 0.5h to 2h and pass through 120 meshes respectively sieve;

[0034] 2) According to mass percentage, mix 55% sieved coal gangue, 35% alumina powder, 3% barium carbonate and 7% alumina chopped fiber to obtain a mixture, put the mixture into a ball mill and then add Mix the gum water solution with a mass concentration of 10% and use alumina ball stone as the grinding medium, control the mass ratio of the grinding ball, the mixture and the gum water solution to 2.5:1:0.35, grind for 0.5h to 3h to form a mixed mud, and the mud is over 300 Mesh sieve;

[0035] Among them, alumina powder is α-alumina or corundum powder for industrial use, its corundum content is > 98%, and the particle diameter of the powder is < 10 μm; The obtained slag-free unidirectionally extended fibers have a d...

Embodiment 3

[0039] 1) Put coal gangue and alumina powder into a ball mill for dry grinding, use alumina ball stone as the grinding medium, control the mass ratio of balls and raw materials to 3:1, ball mill for 0.5h to 2h respectively, and then pass through 120 Mesh sieve;

[0040] 2) According to mass percentage, mix 45% sieved coal gangue, 40% alumina powder, 8% barium carbonate and 7% alumina chopped fiber to obtain a mixture, put the mixture into a ball mill and then add Mix the gum water solution with a mass concentration of 10% and use alumina ball stone as the grinding medium, control the mass ratio of the grinding ball, the mixture and the gum water solution to 3:1:0.38, grind for 0.5h to 3h to form a mixed mud, and the mud is over 300 Mesh sieve;

[0041] Among them, alumina powder is α-alumina or corundum powder for industrial use, its corundum content is > 98%, and the particle diameter of the powder is < 10 μm; The obtained slag-free unidirectionally extended fibers have a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com