A low-temperature synthesis method of monodisperse polymer microspheres

A synthetic method and polymer technology, which is applied in the chemical industry and can solve problems such as denaturation and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

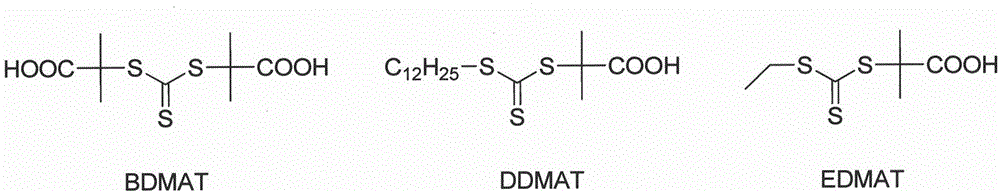

[0034] A low-temperature synthesis method of monodisperse polymer microspheres, characterized in that it comprises steps:

[0035] 1) Dissolving the free radical polymerization monomer, stable dispersant, reversible addition-fragmentation chain transfer agent RAFT, and photoinitiator in the reaction medium;

[0036] 2) After introducing nitrogen gas to remove oxygen, under the stirring state, react under light at 0-90° C. to prepare the monodisperse polymer microspheres.

Embodiment 1

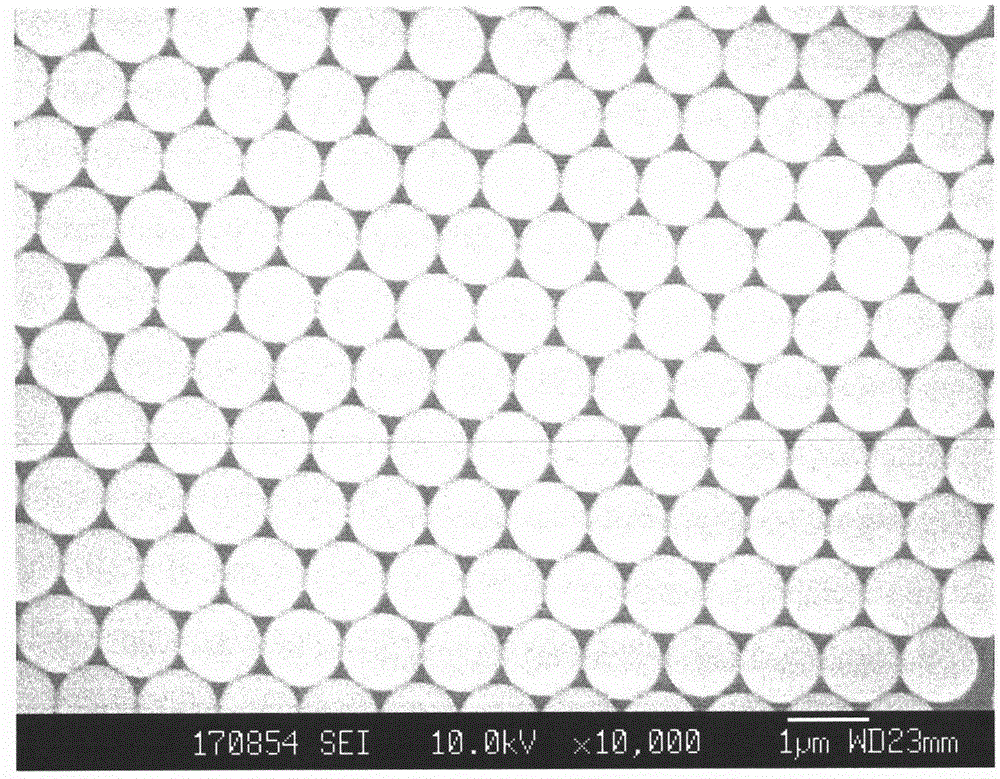

[0038] Such as figure 1 and figure 2As shown, the ethanol / water mixture with a mass ratio of 40 / 60 was placed in a quartz reactor as a reaction medium, and then 10% (relative to the reaction medium) methyl methacrylate (MMA) monomer, 15% polyethylene Pyrrolidone (PVP) stabilizer, 0.5% reversible addition-fragmentation chain transfer agent RAFT (BDMAT), 2% 2-hydroxyl-2-methyl-1-phenylacetone-1 (Ciba company trade name is Darocur1173) The photoinitiator is dissolved in the reaction medium. The reaction mixture was purged with nitrogen for 15 minutes to drive off oxygen and then sealed. Under magnetic stirring, the reaction mixture was irradiated from the top of the reactor with an LED light source with a wavelength of 365 nm (power 3 watts) for 3 hours, and then the light source was turned off. The reaction product was precipitated by a centrifuge, the clear liquid was removed, washed several times with the ethanol / water mixture (40 / 60) in the same ratio as the reaction medi...

Embodiment 2

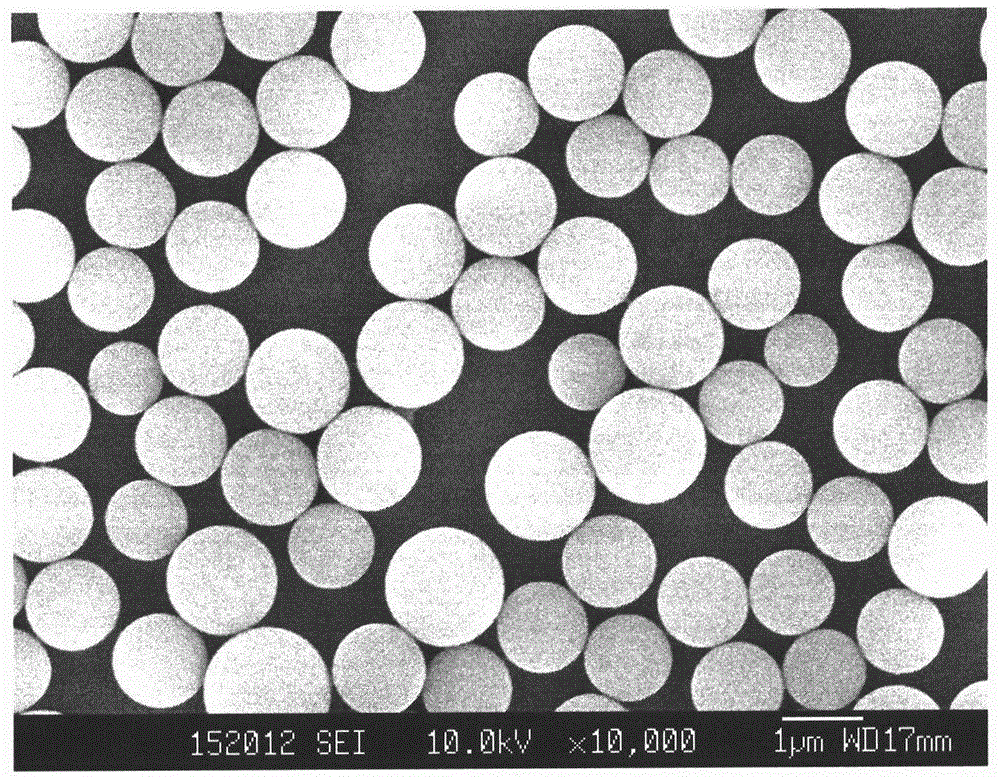

[0042] Such as Figure 4 As shown, the concentration of the reversible addition-fragmentation chain transfer agent RAFT (BDMAT) used in this example is 0.25%, and the rest of the reagents, their dosages, and implementation steps are the same as in Example 1. The yield obtained was 95%. The shape of the product was observed by SEM, and it was a uniform spherical shape. The weight-average diameter (Dw) of all microspheres obtained from the SEM pictures was 1.00m, and the standard deviation rate (CV) was 1.61.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com