Preparation method of water-soluble N-acetyl-L-cysteic acid-modified CdTe quantum dot

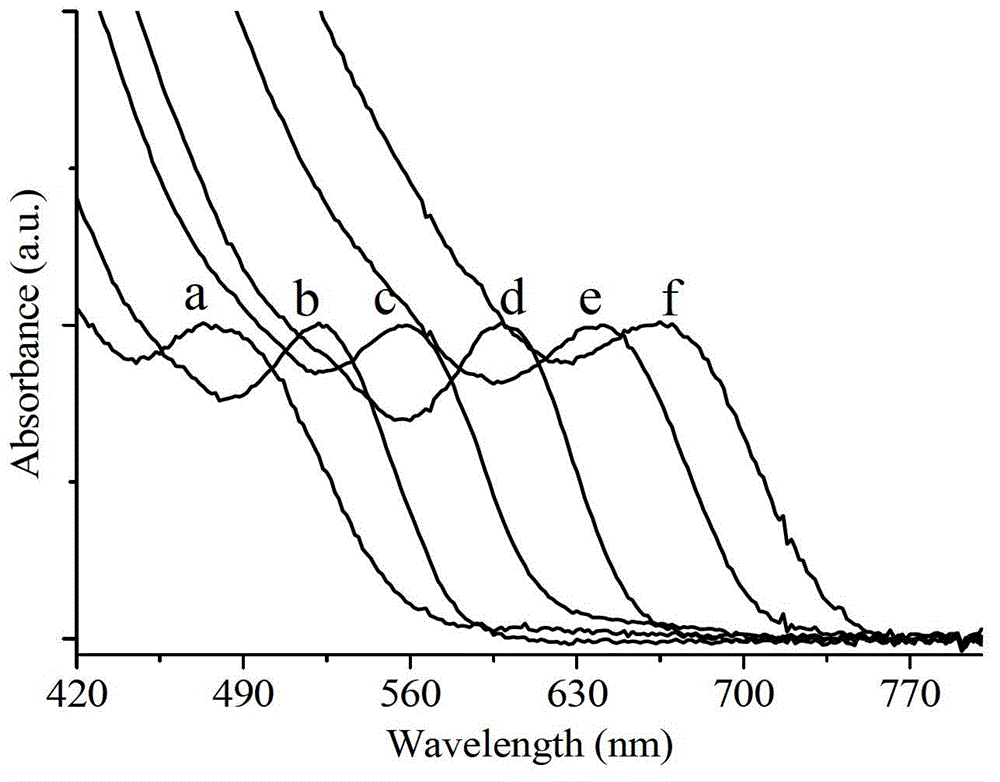

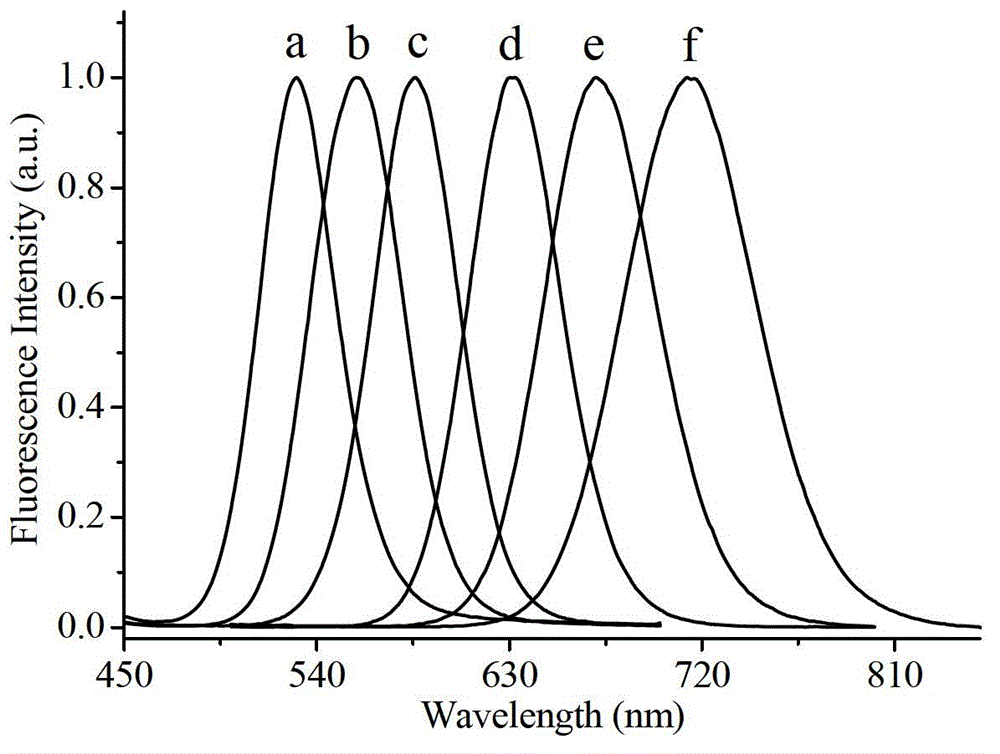

A cysteine and water-soluble technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of limiting the application of CdTe quantum dots, poor biocompatibility, and instability of small molecules, and achieve low cost and biophase Good capacity, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of water-soluble N-acetyl-L-cysteine modified CdTe quantum dots, the steps are as follows:

[0023] (1) Preparation of sodium telluride hydride NaHTe solution

[0024] 0.2mmol Te powder and 0.4mmol NaBH 4 Put it into a two-necked flask, add 5mL of distilled water, protect it with nitrogen, and react at 70°C for 1h to obtain a sodium telluride hydride NaHTe solution for later use;

[0025] (2) Preparation of CdTe quantum dots

[0026] 0.02mmol CdCl 2 Dissolve 0.02mmol N-acetyl-L-cysteine in 40mL distilled water, adjust the pH value to 8.0 with 1mol / L NaOH solution, add 50μL sodium telluride hydride NaHTe solution, protect with nitrogen, and heat to reflux at 70°C for 5min , 40 mL of water-soluble CdTe quantum dot solution with adjustable fluorescence emission wavelength and high fluorescence quantum yield can be obtained.

Embodiment 2

[0028] A preparation method of water-soluble N-acetyl-L-cysteine modified CdTe quantum dots, the steps are as follows:

[0029] 1. Preparation of potassium hydride telluride KHTe solution

[0030] 0.4mmol Te powder and 2.0mmol KBH 4 Put it into a two-necked flask, add 4mL of distilled water, protect it with nitrogen, and react at 90°C for 12h to obtain potassium telluride hydride KHTe solution for later use;

[0031] 2. Preparation of CdTe quantum dots

[0032] 0.4mmol CdBr 2 Dissolve 0.8mmol N-acetyl-L-cysteine in 20mL distilled water, adjust the pH value to 10.0 with 1mol / L NaOH solution, add 2mL potassium telluride hydride KHTe solution, protect with nitrogen, and heat at reflux at 90°C for 35min , 20 mL of water-soluble CdTe quantum dot solution a with adjustable fluorescence emission wavelength and high fluorescence quantum yield can be obtained.

Embodiment 3

[0034] A preparation method of water-soluble N-acetyl-L-cysteine modified CdTe quantum dots, the steps are as follows:

[0035] 1. The preparation of potassium hydride telluride KHTe solution is the same as step 1 of embodiment 2. The preparation of potassium hydride telluride KHTe solution.

[0036] 2. Preparation of CdTe quantum dots The rest of the conditions are the same as step 2. Preparation of CdTe quantum dots in Example 2, only the reaction time is changed to 42min, then 20mL of quantum dot solution b is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com