Heat insulating sludge drying incineration device and heat insulating sludge drying incineration method

A sludge incineration and sludge drying technology, which is applied in combustion methods, dehydration/drying/concentrated sludge treatment, incinerators, etc., can solve the problem of being easily affected by ambient temperature and humidity, easily polluting the atmosphere, and water embankments , Soil, sludge transportation distance and other problems, to save investment costs and later management costs, to achieve the effect of sludge reduction and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

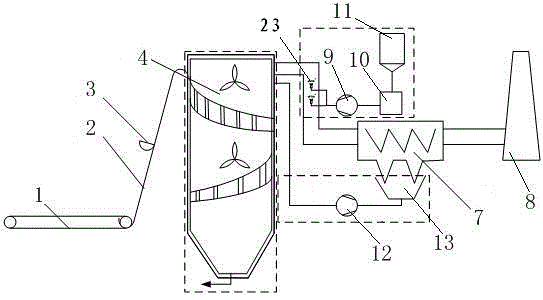

[0034] like figure 1 , 2 , 4, and 5, the following parts of this embodiment describe the adiabatic sludge drying and incineration device and method:

[0035] The adiabatic sludge drying and incineration device includes conveyor 1, elevator 2, sludge hopper 3, sludge incinerator 4, activated carbon injection system, fly ash recycling system, dust collector 7, chimney 8, and the sludge passes through conveyor 1 Sent to the elevator 2, and then lifted by the sludge hopper 3 to the sludge incinerator 4 through the elevator 2, and enters the sludge incinerator 4 from the sludge inlet for incineration, and the flue gas in the process of sludge incineration passes through the activated carbon injection system The heavy metals and other pollutants in the flue gas are removed, and then the dust and activated carbon particles in the flue gas are removed by the dust collector 7, and the clean flue gas is finally discharged from the chimney 8; the dust and activated carbon particles remo...

Embodiment 2

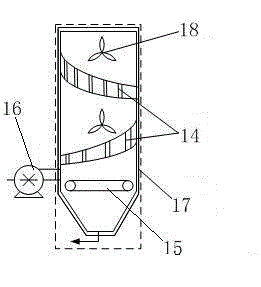

[0044] like image 3 As shown, the difference between this embodiment and Embodiment 1 is only that the furnace type of the sludge incinerator 4 is a fluidized bed furnace.

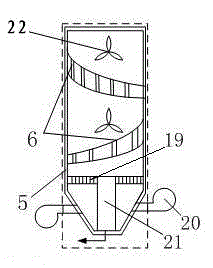

[0045] The main body of the fluidized bed furnace is a fluidized bed furnace body 5, and the fluidized bed furnace body 5 is provided with a fluidized bed furnace equalizer plate net 6, a fluidized bed furnace stirring blade 22, a deflector plate 19, and a fluidization fan 20 , slag leakage door 21, after the sludge enters the fluidized bed furnace body 5, 2-4 grades of fluidized bed furnace equalizing plate nets 6 are arranged along the vertical direction in the furnace, and the top of each level of fluidized bed furnace equalizing plate nets 6 The fluidized bed furnace stirring blade 22 that can rotate is housed, and rotates 0.5~4 weeks per minute. Sludge is put in from the top of the furnace, and on the upper fluidized bed furnace uniform flow plate net 6, it is agitated by the fluidized bed furnace s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com