Modified spinel lithium manganate material and preparation method thereof

A spinel lithium manganate, modification technology, applied in the direction of manganate/permanganate, nanotechnology for materials and surface science, electrical components, etc., can solve the problem of inability to guarantee cycle performance and hinder marketization Application, limited cobalt resources and other issues, to achieve the effects of reducing production costs, inhibiting the John-Teller effect, improving cycle performance and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

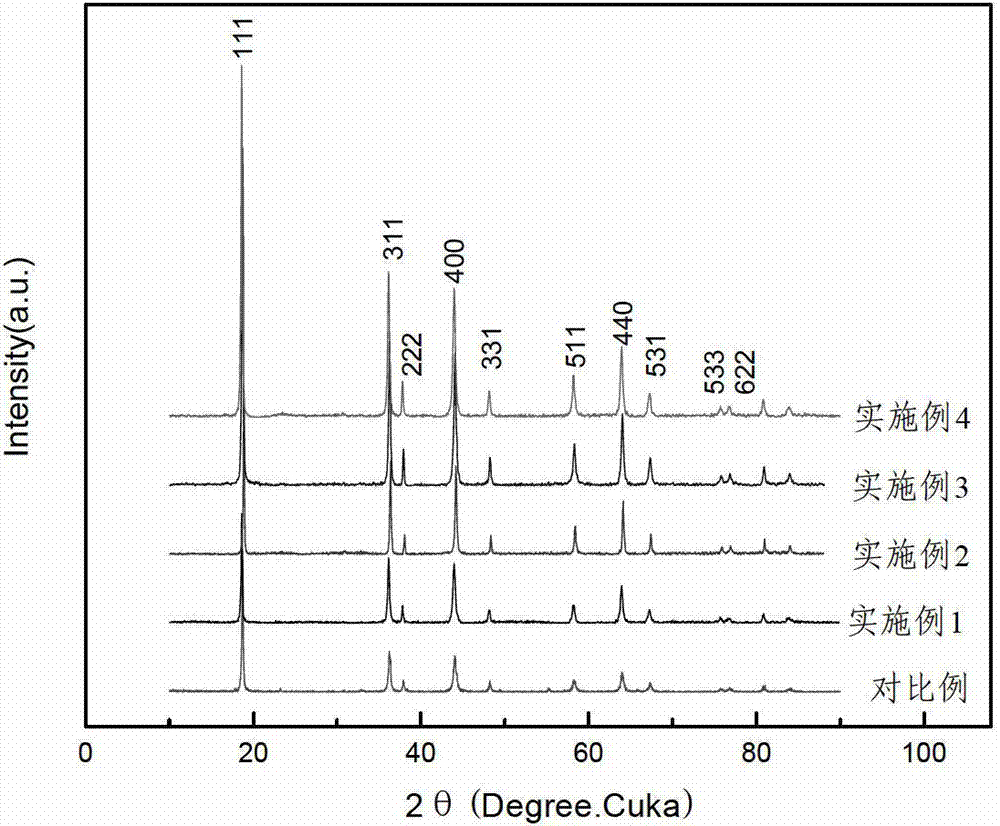

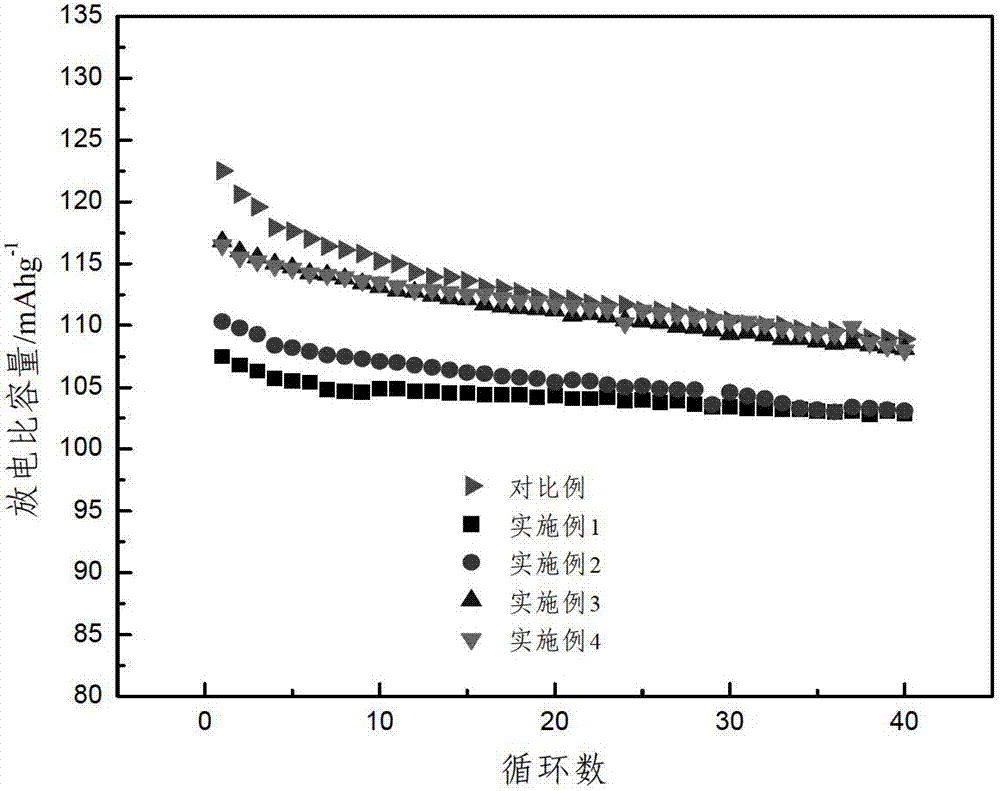

[0026] Using Al, Zn compound doping, its chemical formula is: Li 1.03 al 0.03 Zn 0.03 mn 1.91 o 4 .

[0027] (1) Preparation of xerogel: LiNO 3 , Mn(CH 3 COO) 2 4H 2 O, Al(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O was weighed according to the molar ratio of Li:Mn:Al:Zn of 1.03:1.91:0.03:0.03, ground in a mortar and mixed evenly, dissolved in deionized water at about 1g / mL, and mixed evenly , add citric acid in an amount equal to the sum of the molar amounts of all metal ions, mix and stir evenly, adjust the pH value to 8 with concentrated ammonia water with a mass fraction of 24%, and heat and stir in a water bath at 80°C to evaporate to obtain a light pink wet gel; Dry the wet gel at 120°C for 12 hours to obtain a dry gel;

[0028] (2) Burning: Take the dry gel prepared in step (1) and place it at 480°C for pre-burning treatment for 6 hours, cool it down to room temperature naturally, grind it, and pass it through a 200-mesh sieve; put the ground dry gel at 600°C fo...

Embodiment 2

[0031] Using Zn, Mg composite doping, its chemical formula is: Li 1.03 Zn 0.03 Mg 0.03 mn 1.91 o 4 .

[0032] (1) Preparation of xerogel: LiNO 3 , Mn(CH 3 COO) 2 4H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O was weighed according to the ratio of Li:Mn:Zn:Mg molar ratio of 1.03:1.91:0.03:0.03, ground in a mortar and mixed evenly, dissolved in deionized water at about 1g / mL, and mixed evenly , add citric acid in an amount equal to the sum of the molar amounts of all metal ions, mix and stir evenly, adjust the pH value to 8 with concentrated ammonia water with a mass fraction of 25%, heat and stir in a water bath at 90°C to evaporate, and obtain a light pink wet gel; Dry the wet gel at 130°C for 10-14 hours to obtain a dry gel;

[0033] (2) Burning: Take the dry gel prepared in step (1) and place it at 490°C for pre-burning treatment for 8 hours, cool it down to room temperature naturally, grind it, and pass it through a 220-mesh sieve; place the ground dry gel at...

Embodiment 3

[0036] Using Al, Mg compound doping, its chemical formula is: Li 1.03 al 0.03 Mg 0.03 mn 1.91 o 4 ,

[0037] (1) Preparation of xerogel: LiNO 3 , Mn(CH 3 COO) 2 4H 2 O, Al(NO 3 ) 3 9H 2 O, Mg(NO 3 ) 2 ·6H 2 O is weighed according to the molar ratio of Li:Mn:Al:Mg of 1.03:1.91:0.03:0.03, ground in a mortar and mixed evenly, dissolved in deionized water at about 1g / mL, and mixed evenly , adding citric acid in an amount equal to the sum of the molar amounts of all metal ions, mixing and stirring evenly, adjusting the pH value to 6 with concentrated ammonia water with a mass fraction of 22%, heating and stirring in a water bath at 70°C for evaporation, and obtaining a light pink wet gel; Dry the wet gel at 110°C for 10 hours to obtain a dry gel;

[0038] (2) Burning: Take the dry gel prepared in step (1) and place it at 470°C for pre-burning treatment for 4 hours, cool it down to room temperature naturally, grind it, and pass it through a 180-mesh sieve; put the gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com