Method for removing nitrogen and phosphorus by modifying sintered red mud

A sintering method and red mud technology, applied in the field of water treatment technology and comprehensive utilization of solid waste, to achieve the effects of low price, simple operation and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

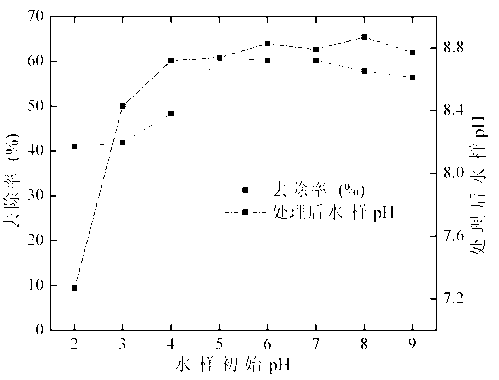

[0019] Example 1 Nitrogen removal effect of modified sintering red mud

[0020] Take 50 mL of untreated water sample containing 20 mg / L ammonia nitrogen and pH 5.0, add 0.5 g of modified sintering red mud, shake at 25 °C and 180 r / min for 1 h, centrifuge to get the supernatant, and use The concentration of ammonia nitrogen determined by Nessler's reagent colorimetry was 6.75 mg / L, the removal rate of ammonia nitrogen was 66.5%, the adsorption capacity of ammonia nitrogen was 1.34 mg / g, and the pH of the treated water sample was 7.9.

Embodiment 2

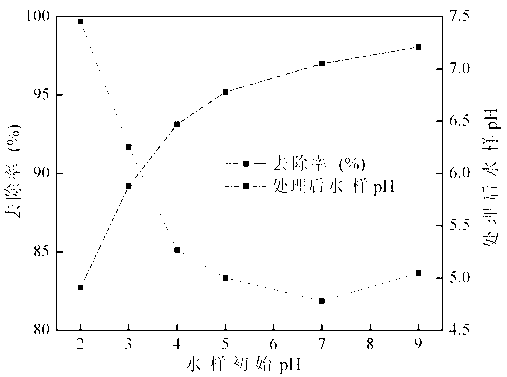

[0021] Example 2 Phosphorus removal effect of red mud by modified sintering method

[0022] Take 40 mL of untreated water sample containing 30 mg / L orthophosphate ion and pH 2.0, add 0.2 g of modified sintering red mud, shake at 25°C and 180 r / min for 4 h, centrifuge to get the supernatant The concentration of orthophosphate was determined by the ammonium molybdate colorimetric method to be 0.09 mg / L, the removal rate of orthophosphate was 99.7%, the adsorption amount of orthophosphate was 5.96 mg / g, and the pH of the treated water sample was 4.9.

Embodiment 3

[0023] Example 3 Application of Modified Sintering Red Mud in Actual Wastewater

[0024] The actual wastewater used in this example was taken from Chengguo River, Tengzhou City, Shandong Province. The concentration of ammonia nitrogen in the water sample was 4.55 mg / L, the concentration of orthophosphate was 0.48 mg / L, and the pH of the water sample was 7.8; 0.5 g of modified The sintering red mud was added to 50 mL of river water, shaken at 25 °C and 180 r / min for 4 h, centrifuged to take the supernatant, and the concentration of ammonia nitrogen was 2.17 mg / L, and the concentration of orthophosphate was 0 mg / L. The removal rate of ammonia nitrogen was 52.2%, the removal rate of orthophosphate was 100%, and the pH of the treated water sample was 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com