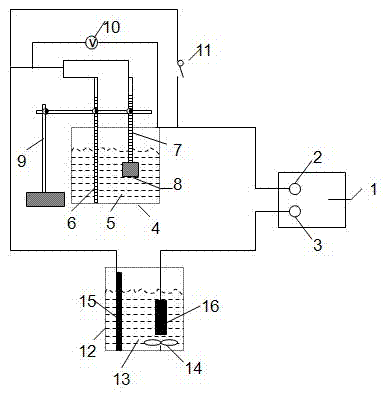

Liquid-phase plasma electrolysis osmosis treatment device

A liquid-phase plasma and treatment device technology, applied in the direction of electrolytic coatings, surface reaction electrolytic coatings, coatings, etc. The effect of large degree, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

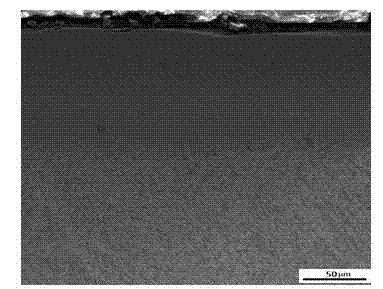

[0023] Embodiment 1: in (NH 2 ) 2 CO+KCl+H 2 In the electrolyte system of O, the anode is a titanium plate, the cathode is 38CrMoAl steel, the size is 2mmx12mmx15mm, the concentration of urea is 20% to 60% (mass fraction), and a pulse-free voltage of 160V to 300V is applied between the anode and cathode, then A liquid-phase plasma arc discharge is formed on the surface of the cathode 38CrMoAl steel, and the discharge time is 2 to 10 minutes. The solitary light and temperature of the sample surface are controlled by adjusting the depth of the first and second wires with scale values in the electrolyte solution. On the 38CrMoAl steel surface of the cathode, a permeated layer with a thickness of 20 μm to 80 μm is formed, the surface is relatively smooth, and the microhardness of the permeated layer is about 600 to 1040HV 0.1 .

Embodiment 2

[0024] Example 2: In HCONH 2 +KCl+H 2 In the electrolyte system of O, the anode is an aluminum plate, the cathode is 38CrMoAl steel, the size is 2mmx12mmx15mm, the concentration of formamide is 20% to 80% (mass fraction), and a pulse-free voltage of 160V to 300V is applied between the anode and cathode, then A liquid-phase plasma arc discharge is formed on the surface of the 38CrMoAl steel at the cathode, and the discharge time is 2 to 10 minutes. When HCONH 2When the concentration is low (the water content has a great influence on the temperature), or when the voltage is high, the temperature and arc are controlled by adjusting the double wires, and a permeation layer with a thickness of 20 μm to 130 μm is formed on the surface of the cathode 38CrMoAl steel, and the surface is dark gray. , bright and clean, the microhardness of the seepage layer is about 600~980HV 0.1 .

Embodiment 3

[0025] Example 3: In NH 3 .H 2 O+KCl+H 2 Under the electrolyte system of O, the anode is stainless steel, the cathode is 38CrMoAl steel, the size is 2mmx12mmx15mm, the concentration of ammonia water is 20% to 80% (mass fraction), and a pulse-free voltage of 160V to 300V is applied between the anode and cathode, then the The 38CrMoAl steel surface of the cathode forms a liquid-phase plasma arc discharge, and the discharge time is 2 to 10 minutes. When NH 3 .H 2 When the concentration of O is low (the water content has a great influence on the temperature), or when the voltage is high, the temperature and arc are controlled by adjusting the double wires, and a permeation layer with a thickness of 20 μm to 180 μm is formed on the surface of the cathode 38CrMoAl steel. The surface is gray, very smooth, and the microhardness of the seepage layer is about 600-950HV 0.1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com